Detection method for decitabine impurities

A technology of citabine and determination method, applied in the field of medical analysis, can solve the problems of poor stability of raw glycosides, low recovery rate, solvent peak interference, etc., and achieve the effects of good recovery rate, high recovery rate and high accuracy of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

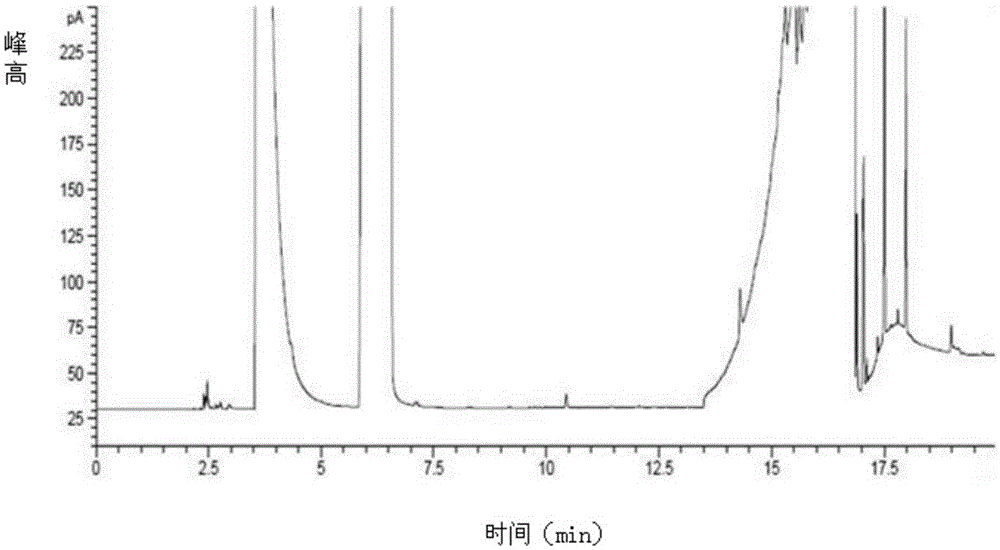

[0072] Chromatographic conditions:

[0073] Column temperature: programmed temperature rise: the initial temperature was 40°C and kept for 8 minutes, then the temperature was raised to 220°C at a rate of 20°C per minute and kept for 19 minutes.

[0074] Injection port temperature: 250°C;

[0075] Flame ionization detector temperature: 300°C;

[0076] Carrier gas: nitrogen;

[0077] Carrier gas flow rate: 3.0ml / min;

[0078] Split ratio: 20:1.

[0079] 1. Detection

[0080] A. Preparation of the test solution:

[0081] First, prepare the mixed solution of methanol-N-methylpyrrolidone-triethylamine at a volume ratio of 47.5:47.5:5 and set aside;

[0082] Again, accurately weigh 1.0 g of glucoside, put it in a 10 ml volumetric flask, dissolve and dilute it into a 0.1 g / ml solution with the prepared mixed solution of methanol-N-methylpyrrolidone-triethylamine, mix well, and set aside;

[0083] B. Preparation of reference substance solution: Accurately weigh 200 μg of pyridi...

Embodiment 2

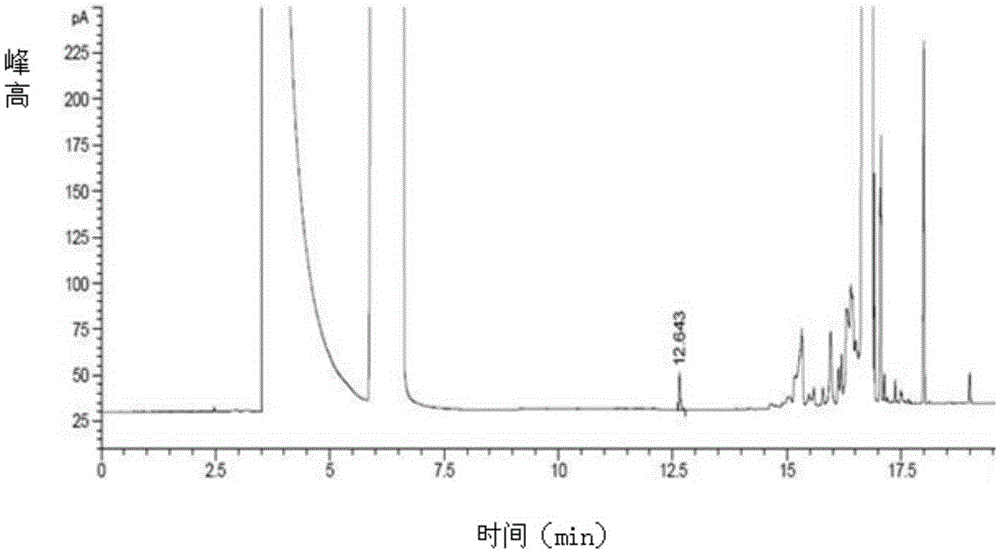

[0127] The difference between this embodiment and embodiment 1 is that the volume ratio of methanol-N-methylpyrrolidone-triethylamine is

[0128] 45:45:10.

[0129] Chromatographic conditions:

[0130] Column temperature: programmed temperature rise: the initial temperature was 40°C and kept for 8 minutes, then the temperature was raised to 220°C at a rate of 20°C per minute and kept for 19 minutes.

[0131] Injection port temperature: 230°C;

[0132] Flame ionization detector temperature: 280°C;

[0133] Carrier gas: nitrogen;

[0134] Carrier gas flow rate: 2.0ml / min;

[0135] Split ratio: 10:1.

[0136] According to the above conditions, three batches of test solution were detected, and no pyridine peak was detected in the chromatograms. After calculation, the residual amount of pyridine in the glycoside was 0%.

Embodiment 3

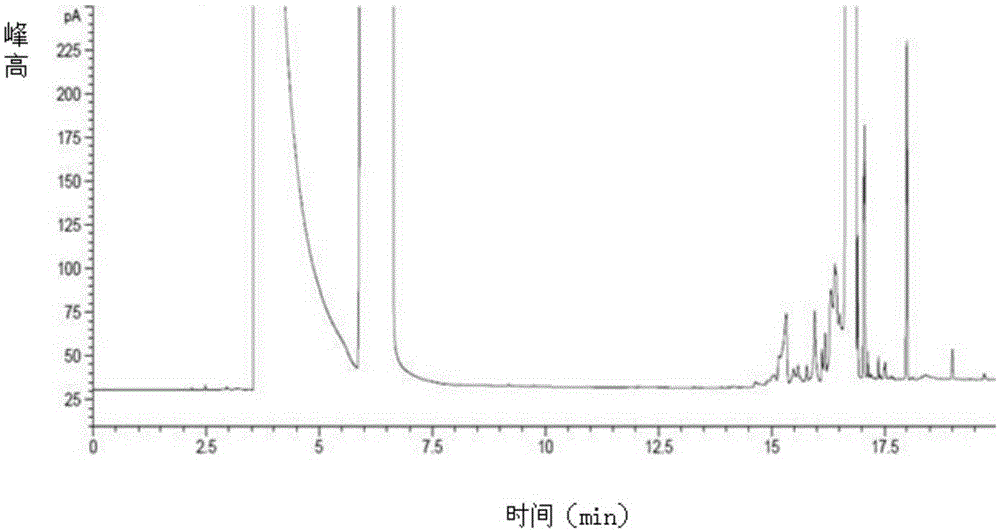

[0138] The difference between this embodiment and embodiment 1 is that the volume ratio of methanol-N-methylpyrrolidone-triethylamine is

[0139] 48:48:4.

[0140] Chromatographic conditions:

[0141] Column temperature: programmed temperature rise: the initial temperature was 40°C and kept for 8 minutes, then the temperature was raised to 220°C at a rate of 20°C per minute and kept for 19 minutes.

[0142] Injection port temperature: 270°C;

[0143] Flame ionization detector temperature: 320°C;

[0144] Carrier gas: nitrogen;

[0145] Carrier gas flow rate: 4.0ml / min;

[0146] Split ratio: 30:1.

[0147] According to the above conditions, three batches of test solution were detected, and no pyridine peak was detected in the chromatograms. After calculation, the residual amount of pyridine in the glycoside was 0%.

[0148] In addition, other residual solvents in the test product can also be detected according to the methods provided in the above-mentioned Examples 1 to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com