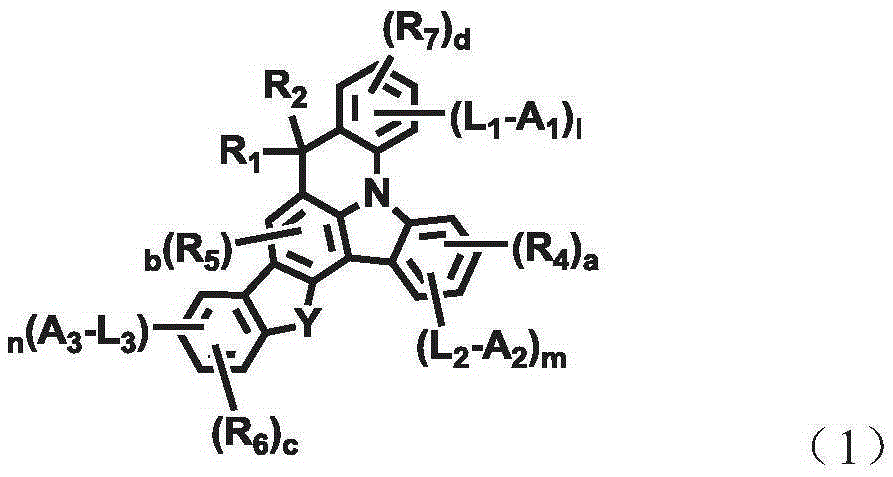

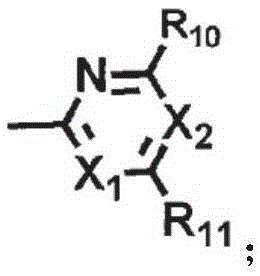

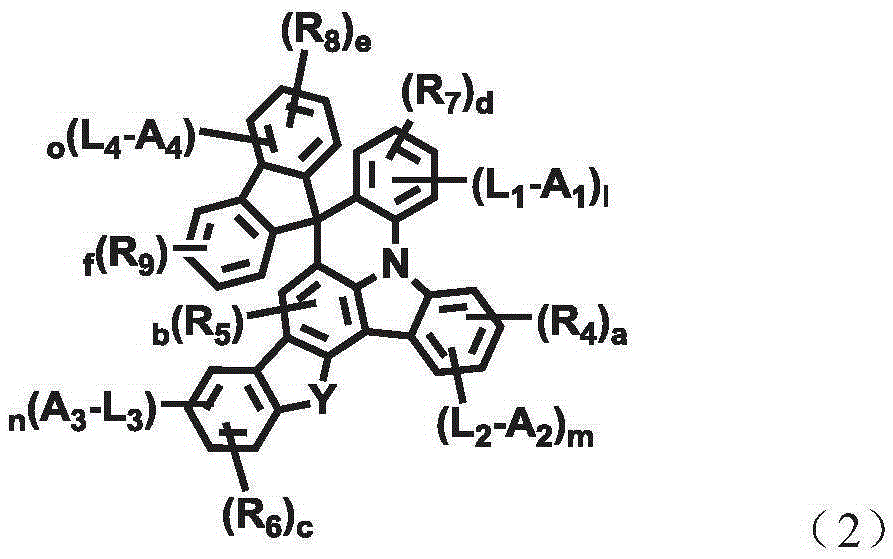

Novel organic electroluminescent compounds and organic electroluminescent device comprising the same

A compound and luminescent technology, applied in organic chemistry, luminescent materials, chemical instruments and methods, etc., can solve the problems of high driving voltage, decomposition, low glass transition temperature, etc., achieve high electron transmission efficiency, reduce voltage requirements, Effect of Improving Current Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0097] Example 1: Preparation of compound H-2

[0098]

[0099] Preparation of compound H-2-2

[0100] Compound H-2-1 (60.0 g, 263.0 mmol), 2-bromonitrobenzene (44.2 g, 219.0 mmol), tetrakis(triphenylphosphine)palladium(0) were stirred at reflux in a 2L round bottom flask (RBF). [Pd(PPh 3 ) 4 ] (7.6g, 6.57mmol), K 2 CO 3 (60.5g, 438.0mmol), toluene (900.0mL), ethanol (EtOH) (220.0mL) and H 2 O (220.0 mL). After 5 h, the mixture was washed with dichloromethane (DCM) and H 2 O extraction, and DCM layer in MgSO 4 Dry and filter. The resulting solid was dissolved in CHCl 3 and separated by silica gel column chromatography to obtain compound H-2-2 (74.8 g, 93%).

[0101] Preparation of compound H-2-3

[0102] Compound H-2-2 (74.8g, 245.0mmol), triethyl phosphite [P(OEt) 3 ] (500.0 mL) and 1,2-dichlorobenzene (1,2-DCB) (200.0 mL). After 13 hours, the solvent was distilled off and the solid was dissolved in CHCl 3 and separated by silica gel column chromatograph...

example 2

[0119] Device Example 2: Fabrication of OLED Devices Using Organic Electroluminescent Compounds of the Invention

[0120] An OLED device was fabricated in the same manner as in Device Example 1, except that Compound H-2 as a host was introduced into one unit of a vacuum vapor deposition apparatus, Compound D-88 as a dopant was introduced into the other unit, and both The materials were evaporated at different rates and the dopant was deposited at a doping amount of 4% by weight based on the total weight of the host and the dopant, forming a light-emitting layer with a thickness of 30 nm on the hole transport layer. Next, 2-(4-(9,10-bis(naphthalene-2-yl)anthracen-2-yl)phenyl)1-phenyl-1H-benzo[d]imidazole was introduced into one unit, and Lithium quinolate was introduced in one unit, and the two materials were evaporated at the same rate and deposited at a doping amount of 50% by weight, respectively, to form an electron transport layer with a thickness of 30 nm on the light e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com