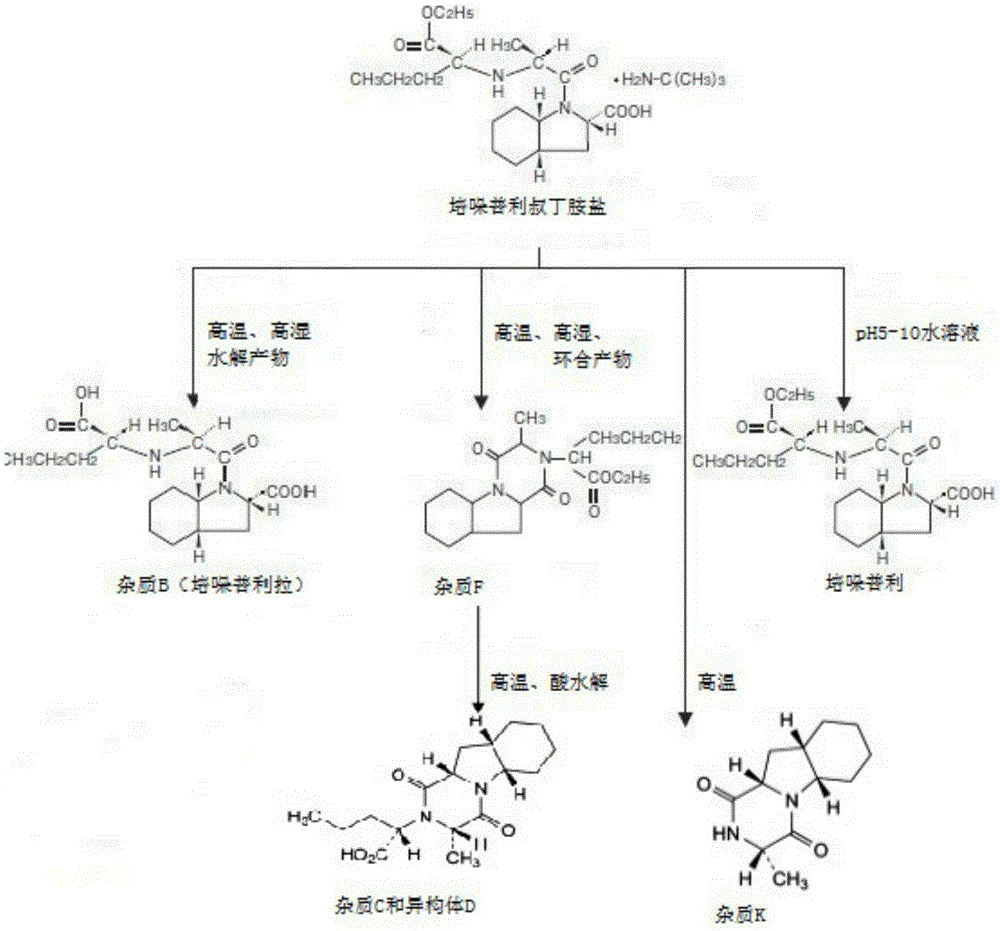

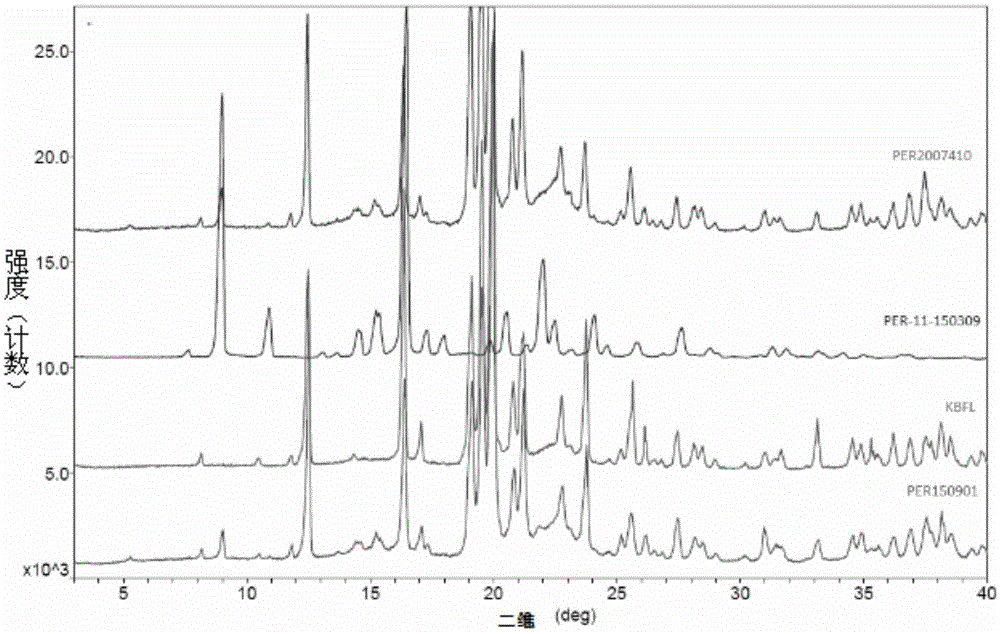

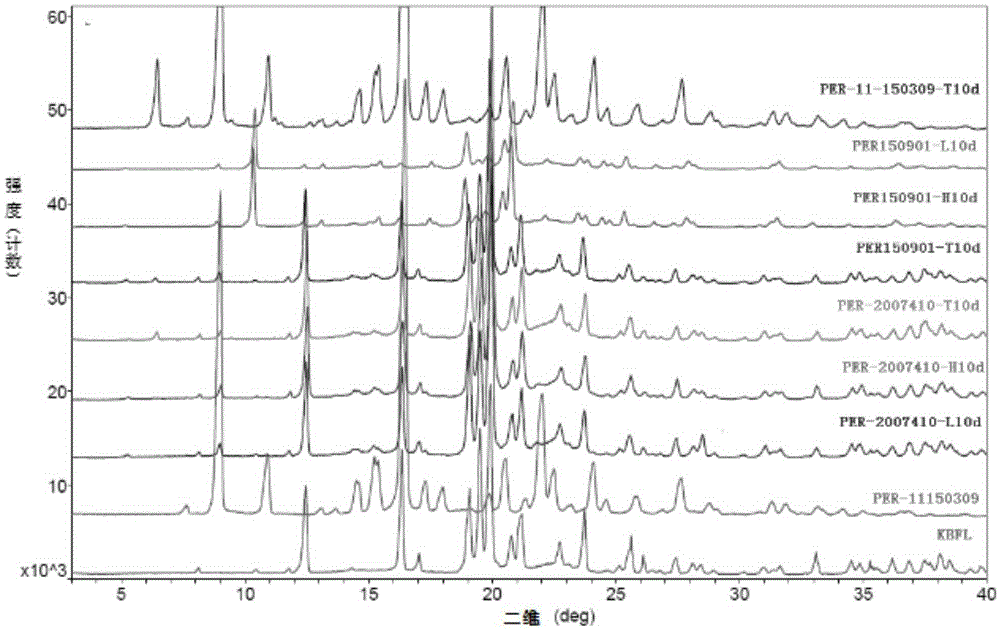

Stable alpha-crystalline form perindopril tert-butylamine tablet and preparation method thereof

A technology of tert-butylamine tablets and perindopril, which is applied in the field of medicine, can solve the problems of impurity degradation rate and crystal form transformation, and achieve the effects of reducing moisture control and disintegration risk, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of perindopril tablet, described perindopril tablet is made up of following components according to parts by weight:

[0039] Alpha crystal form perindopril tert-butylamine: 4 parts;

[0040] Lactose: 65 parts;

[0041] Microcrystalline cellulose: 20 parts;

[0042] Magnesium stearate: 1 part.

[0043] The tablet weighing about 90mg of last system, its preparation process comprises the following steps:

[0044] (1) Take lactose and microcrystalline cellulose and pass through a 50-mesh sieve respectively, mix, dry until the moisture is lower than 4.5%, divide into 3 parts, and control the humidity in the process to be lower than 40% RH.

[0045] (2) Take one portion and mix it with perindopril tert-butylamine passing through a 80-mesh sieve, and pass through a 60-mesh sieve to mix;

[0046] (3) Continue to add a part of the mixed auxiliary materials in (1) and mix;

[0047] (4) Mix (3) with the remaining auxiliary materials in (1) for 20 minutes;

[0048] (5) ...

Embodiment 2

[0055] A kind of perindopril tablet, described perindopril tablet is made up of following components according to parts by weight:

[0056] Alpha crystal form perindopril tert-butylamine: 4 parts;

[0057] Lactose: 60 parts;

[0058] Microcrystalline cellulose: 25 parts;

[0059] Magnesium stearate: 1 part.

[0060] The tablet weighing about 90mg of last system, its preparation process comprises the following steps:

[0061] (1) Take lactose and microcrystalline cellulose and pass through a 50-mesh sieve respectively, mix, dry until the moisture is lower than 4.5%, divide into 3 parts, and control the humidity in the process to be lower than 40% RH;

[0062] (2) Take one portion and mix it with perindopril tert-butylamine through a 60-mesh sieve, and mix evenly through a 60-mesh sieve;

[0063] (3) Continue to add a part of the mixed auxiliary materials in (1) and mix;

[0064] (4) Mix (3) with the remaining auxiliary materials in (1) for 20 minutes;

[0065] (5) Add mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com