Composite nanodot based on carbon nanodot and preparation technology thereof

A technology of carbon nano-dots and preparation process, which is applied in preparations for in vivo experiments, luminescent/biological dyeing preparations, drug delivery, etc., can solve problems such as poor stability, high sex-to-noise ratio, short metabolic cycle, etc., and achieve stability Good, good monodispersity, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

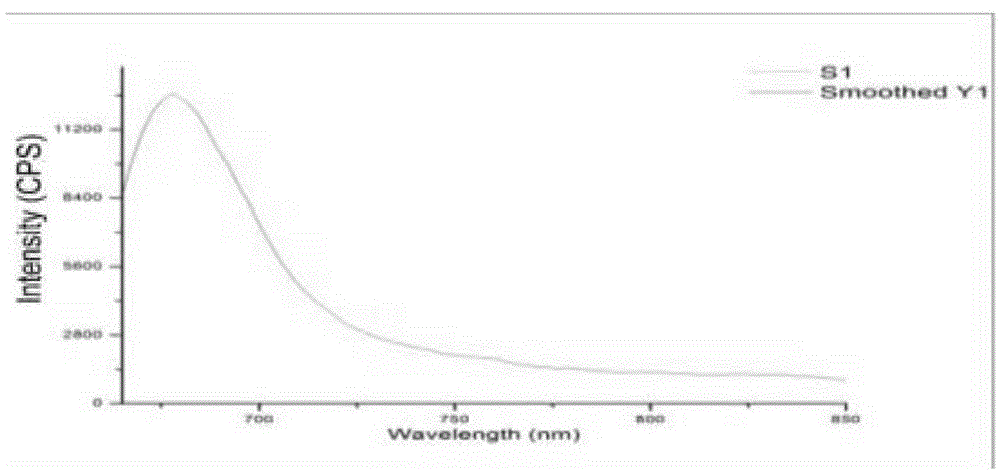

[0033] Example 1: Take 2 milliliters of Lycium barbarum extract and 2 milliliters of methylene blue solution (0.5 mg / ml) and mix them, and dilute it with ultra-pure water 1 time to prepare a precursor solution, put the precursor solution into a 5 milliliter microwave reactor special glass bottle, And it was placed in a microwave reactor, and the reaction conditions were set at 180 degrees Celsius for 30 minutes. The reaction system was left to stand for 50 minutes, centrifuged, and the supernatant liquid was retained, and the composite carbon nano-dots were obtained after ultrafiltration. The concentration of methylene blue in the composite nano-dots measured by the ultraviolet spectrophotometer standard curve method is 5.6 micrograms per milliliter; measured by the laser particle size analyzer based on the principle of dynamic light scattering, the particle size distribution of the composite carbon nano-dots is 179 ± 77.1 nanometers (see attached Figure 2a ), the surface pot...

Embodiment 2

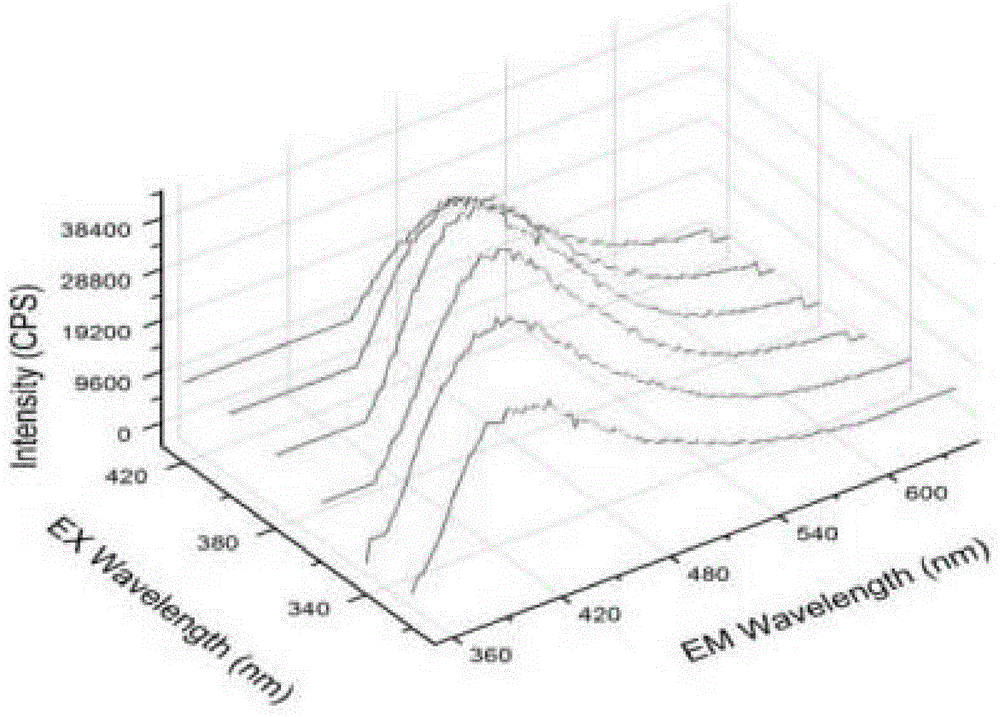

[0034] Example 2: Mix 10 ml of freshly ground soybean milk with 1 ml of methylene blue solution (0.5 mg / ml) and dilute it 10 times with ultrapure water to prepare a precursor solution. Take 5 ml of the precursor solution and put it into a 5 ml microwave reactor glass bottle, and it was placed in a microwave reactor, and the reaction conditions were set at 100 degrees Celsius for 5 hours. The reaction system was left to stand for 60 minutes, then centrifuged, and the supernatant liquid was retained, and the composite carbon nano-dots were obtained after ultrafiltration. The concentration of methylene blue in the composite carbon nano-dots was measured to be 8.6 μg / ml by the UV spectrophotometer standard curve method. According to the principle of dynamic light scattering and measured by laser particle size analyzer, the particle size distribution of the composite carbon nano-dots supported by methylene blue is 197.9±79.7 nm (see attached Figure 3a ), the surface potential is ...

Embodiment 3

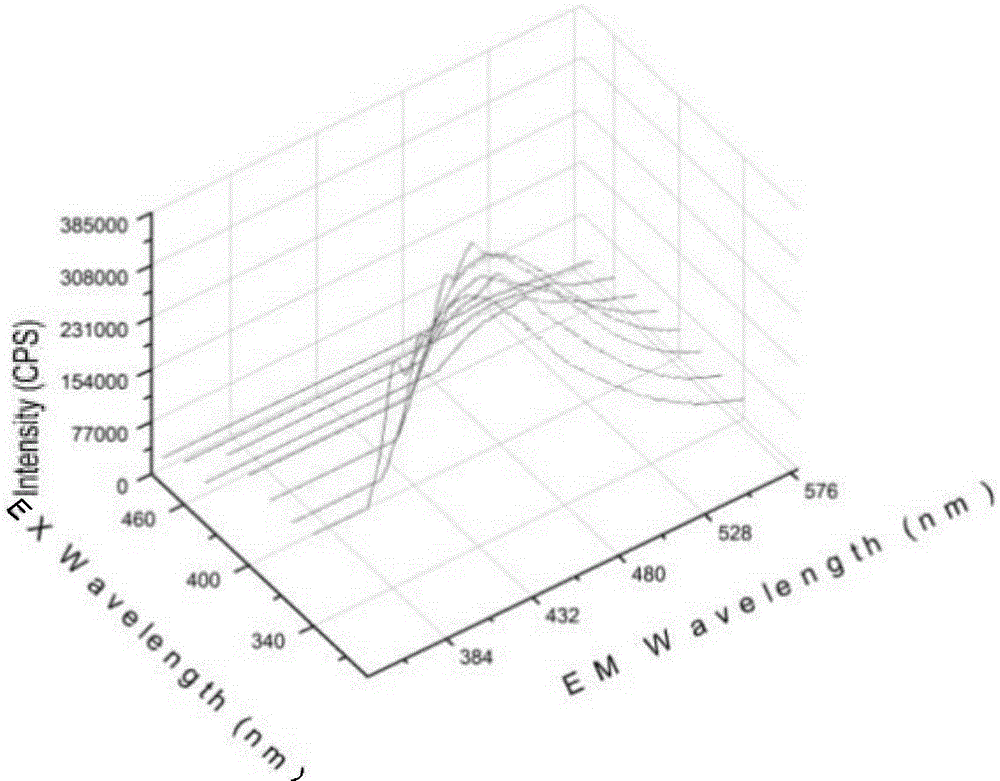

[0035] Example 3: Mix 1 ml of edible milk with 10 ml of methylene blue solution (0.5 mg / ml) and dilute it 5 times with ultrapure water to prepare a precursor solution, take 5 ml of the precursor solution and put it into 5 ml of special glass for microwave reactor bottle, and it was placed in a microwave reactor, and the reaction conditions were set at 160 degrees Celsius for 2 hours. The reaction system was left to stand for 1 hour, and the supernatant was retained by centrifugation, and the composite carbon nano-dots were obtained after dialysis treatment. The concentration of methylene blue in the composite carbon nano-dots measured by the standard curve method was 1.8 μg / ml. According to the principle of dynamic light scattering and measured by a laser particle size analyzer, the particle size of the composite carbon nano-dots loaded with methylene blue is 434.4±196.8 nanometers (see attached Figure 4a ), the surface potential is 4.92±2.88 mV (see attached Figure 4b); t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com