A kind of protein and sugar grafting reaction equipment and preparation method of glycosylated protein

A technology of grafting reaction and protein, applied in the field of protein deep processing, can solve the problems of low production efficiency, discontinuous reaction, long grafting reaction time of protein and sugar, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

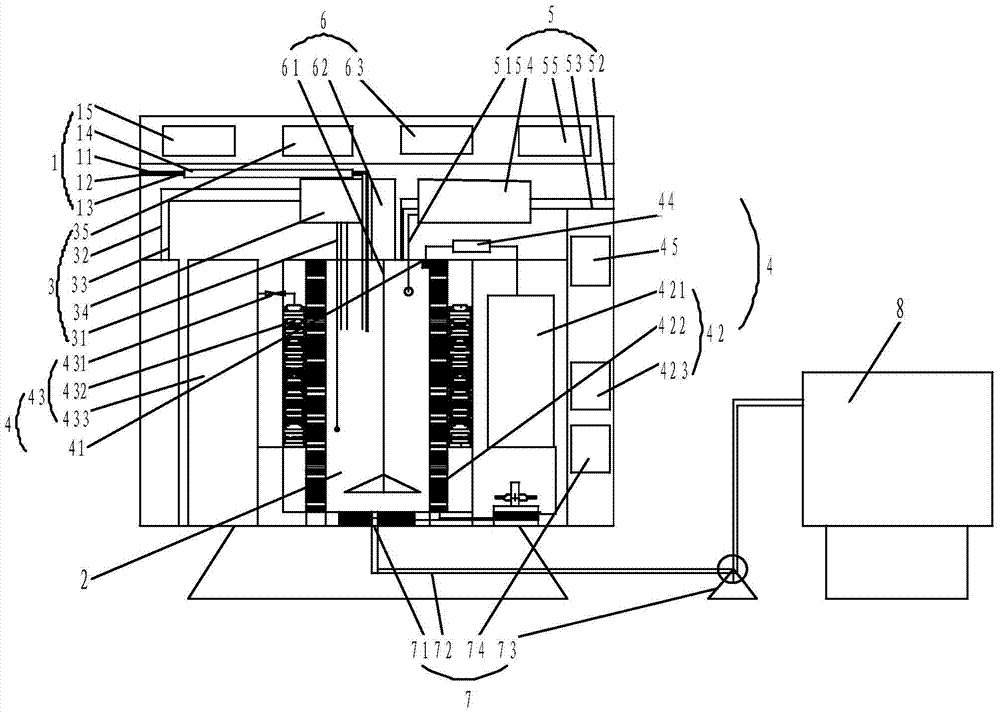

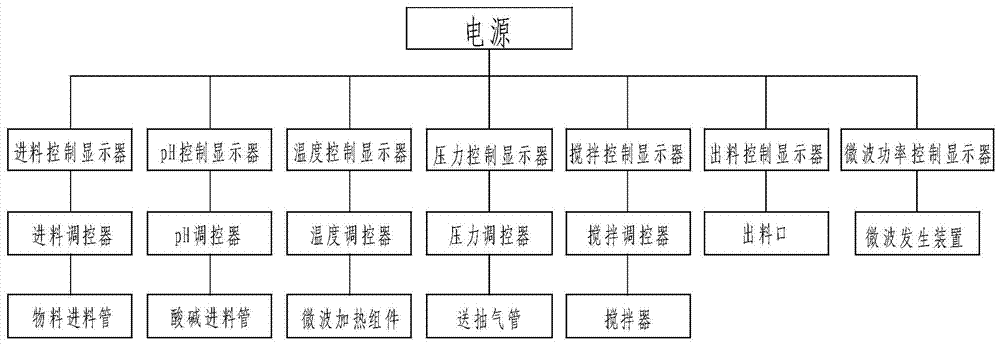

Method used

Image

Examples

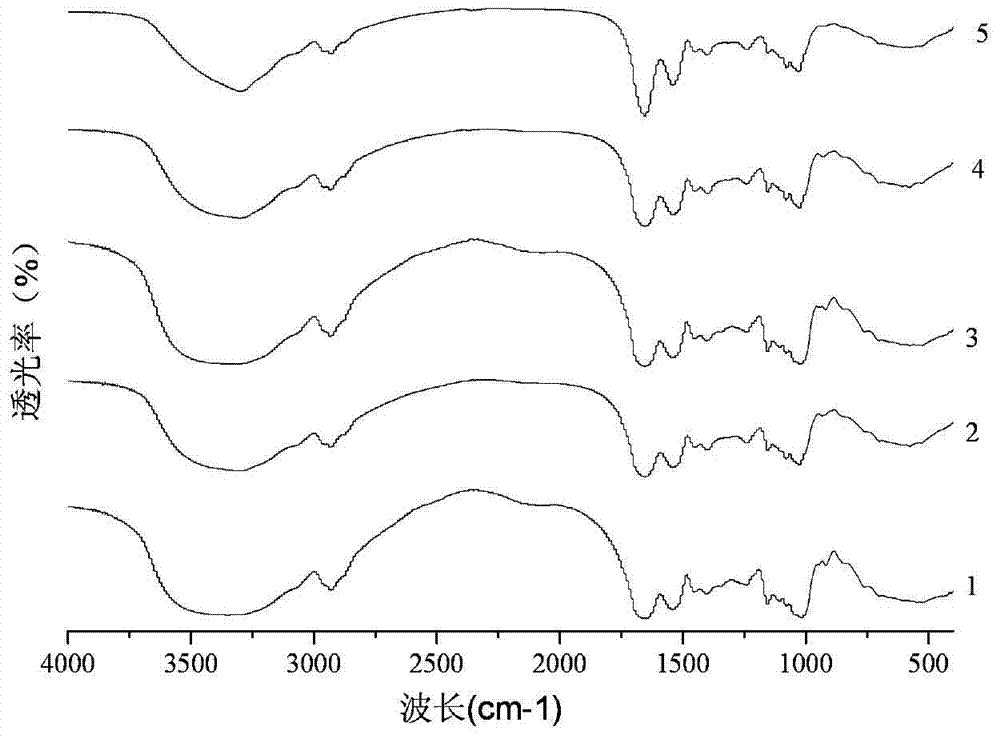

Embodiment 1

[0046] 1) Set the amount of rice protein required for the grafting reaction on the feed control display to be 10g, and the amount of distilled water to be set to 1000mL;

[0047] 2) Set the pH required for preparing the protein solution on the pH control display to 12, and set the stirring speed required for preparing the protein solution on the stirring control display to 300r / min;

[0048] 3) Start the grafting reaction equipment, the reaction time is 30min, and suspend the equipment after making protein solution;

[0049] 4) The amount of sugar required for the grafting reaction is set to 30g on the feed control display, and the connection is set on the pH control display, temperature control display, microwave power control display, pressure control display, stirring control display and discharge control display. The pH required for the branching reaction is 10.5, the temperature is 110°C, the microwave power is 100W, the pressure is 100MPa, the stirring speed is 300r / min,...

Embodiment 2

[0052] The difference from Example 1 is:

[0053] In step 1), the amount of rice protein added is set to 20g, the amount of distilled water is set to 1500mL, and the stirring speed of the protein liquid is 400r / min;

[0054] The sugar added in step 4) is maltodextrin, the added amount is set to 60g, the reaction temperature is 100°C, the microwave power is 300W, the pressure is 80MPa, the stirring speed is 400r / min, and the reaction time is 15min.

Embodiment 3

[0056] The difference from Example 1 is:

[0057] In step 1), the amount of rice protein added is set to 10g, the amount of distilled water is set to 1500mL, and the stirring speed of the protein liquid is 500r / min;

[0058] The sugar added in step 4) is glucose, the amount added is 20g, the reaction temperature is 90°C, the microwave power is 500W, the pressure is 60MPa, the stirring speed is 500r / min, and the reaction time is 25min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com