Preparation method of ceramic membrane loaded zinc oxide photocatalyst

A technology of photocatalyst and ceramic membrane, which is applied in the field of catalysis to achieve the effects of improving activity, avoiding separation of catalyst and product, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

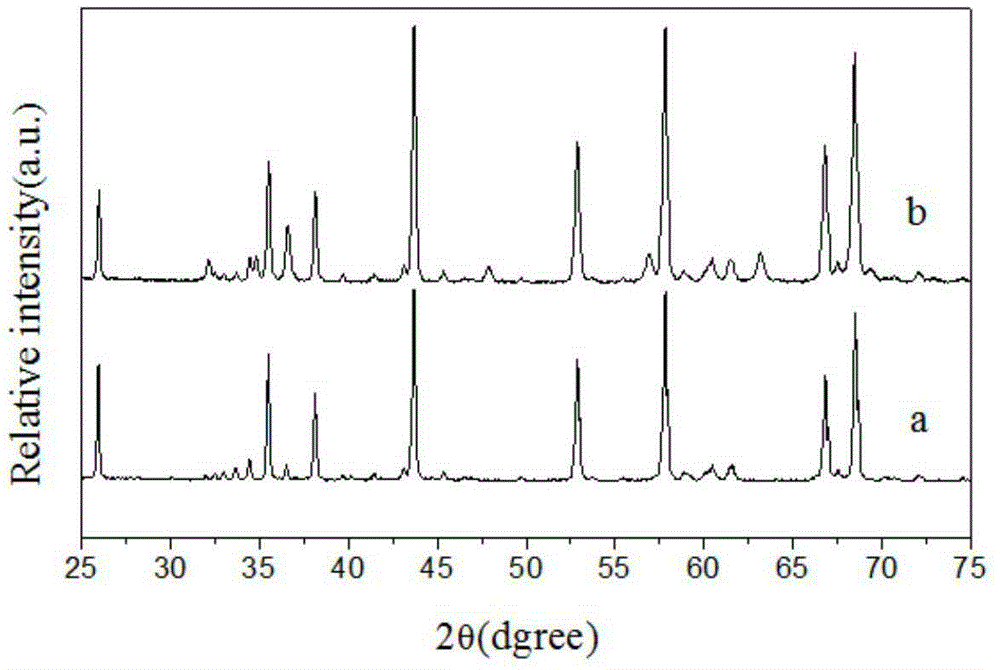

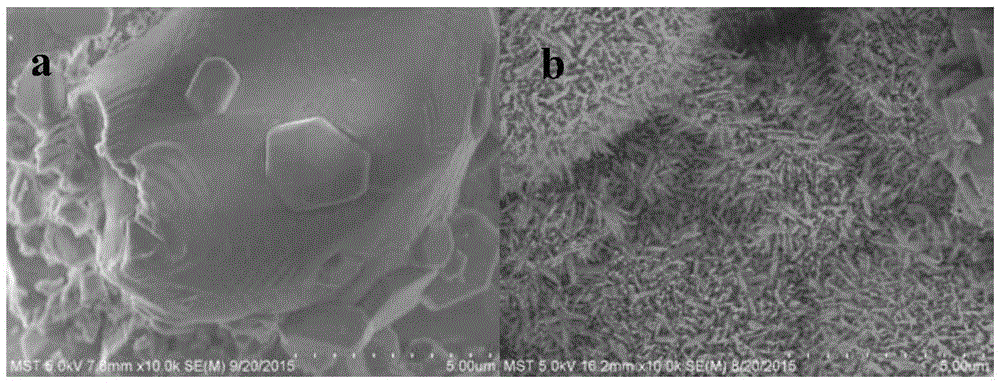

Embodiment 1

[0024] Measure 7.3384g of anhydrous zinc acetate and 2.4mL of ethanolamine into 80mL of ethylene glycol methyl ether, stir at 60°C for 40min to prepare a seed crystal growth solution with a concentration of 0.5mol / L. Soak Al in deionized water 2 o 3 Membrane tube, the length of the membrane tube is 6cm, the outer diameter is 12mm, the inner diameter is 8mm, the membrane pore diameter is 5000nm, and it is dried for later use. Fix the membrane tube on the immersion pulling machine, control the pulling speed to 3200 μm / s, and the immersion time to 10s. Then the ceramic membrane tube was placed in a muffle furnace and calcined at 600° C. for 40 min, and calcined twice. Weigh 1.7849g of zinc nitrate hexahydrate and 0.4206g of hexamethyleneimine into 160mL of deionized water, stir at room temperature for 40min to prepare a hydrothermal solution with a zinc nitrate hexahydrate concentration of 0.075mol / L (amine-zinc molar ratio 0.5:1), while adding 0.45 mL of 1,3-propylenediamine ...

Embodiment 2

[0028] Measure 9.6327g of anhydrous zinc acetate and 3.1mL of ethanolamine into 70mL of ethylene glycol methyl ether, stir at 60°C for 40min to prepare a seed crystal growth solution with a concentration of 0.75mol / L. Soak TiO with deionized water 2 Membrane tube, the length of the membrane tube is 6cm, the outer diameter is 12mm, the inner diameter is 8mm, the membrane pore diameter is 500nm, and it is dried for later use. Fix the film tube on the immersion pulling machine, control the pulling speed to 2500 μm / s, and the immersion time to 20s. Then the ceramic membrane tube was placed in a muffle furnace, and calcined at 300° C. for 20 min, and calcined three times. Weigh 1.1899g of zinc nitrate hexahydrate and 1.0134g of hexamethyleneimine into 80mL of deionized water, stir at room temperature for 40min to prepare a hydrothermal solution with a zinc nitrate hexahydrate concentration of 0.1mol / L (amine-zinc molar ratio 2:1), while adding 0.35 mL of 1,3-propylenediamine (the...

Embodiment 3

[0031] Measure 3.2109g of anhydrous zinc acetate and 1mL of ethanolamine into 70mL of ethylene glycol methyl ether, stir at 60°C for 40min to prepare a seed crystal growth solution with a concentration of 0.25mol / L. Soak ZrO in deionized water 2 , the length of the membrane tube is 6cm, the outer diameter is 12mm, the inner diameter is 8mm, the membrane pore diameter is 5nm, and it is dried for later use. Fix the membrane tube on the immersion pulling machine, control the pulling speed to 3000 μm / s, and the immersion time to 15s. Then the membrane tube was placed in a muffle furnace and calcined at 400° C. for 60 min, and calcined four times. Weigh 0.8929g of zinc nitrate hexahydrate and 0.6304g of hexamethyleneimine into 80mL of deionized water, stir at room temperature for 40min to prepare a hydrothermal solution with a zinc nitrate hexahydrate concentration of 0.075mol / L (amine-zinc molar ratio 1.5:1), while adding 0.5 mL of 1,3-propylenediamine (the molar ratio of 1,3-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com