Resistance reducing agent, resistance reducing solution containing resistance reducing agent, and application of resistance reducing solution

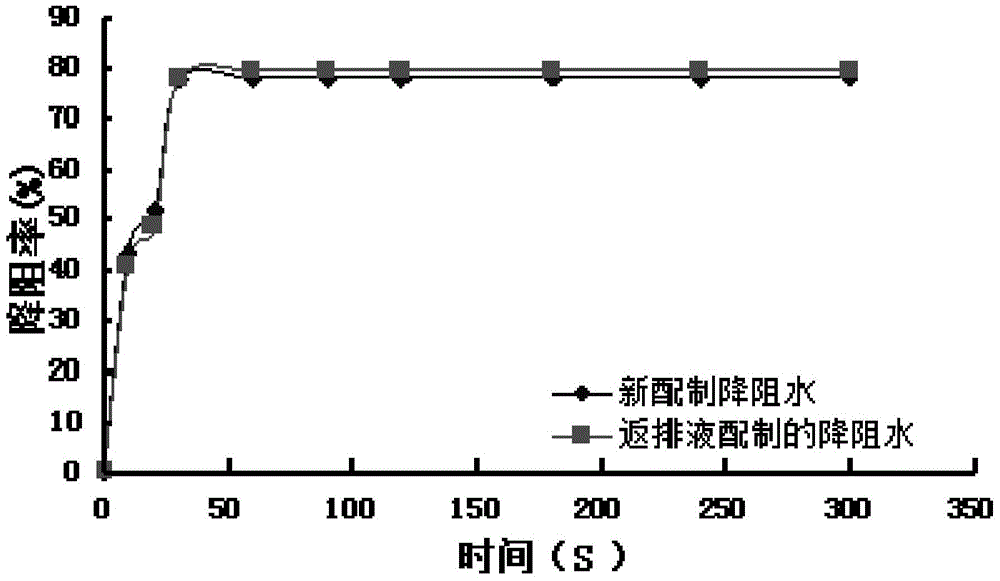

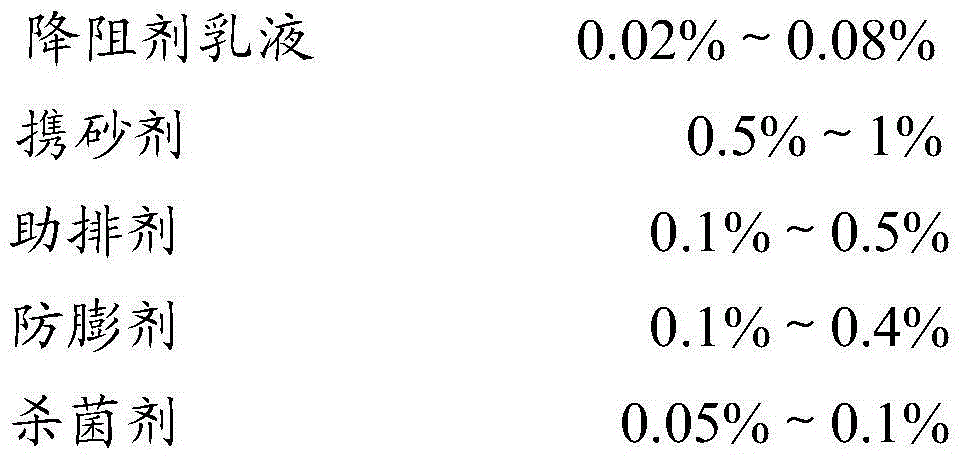

A drag-reducing agent and water-resistance reducing technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of reservoir damage, drag-reducing agent cannot be degraded, etc. The effect of improving sand-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

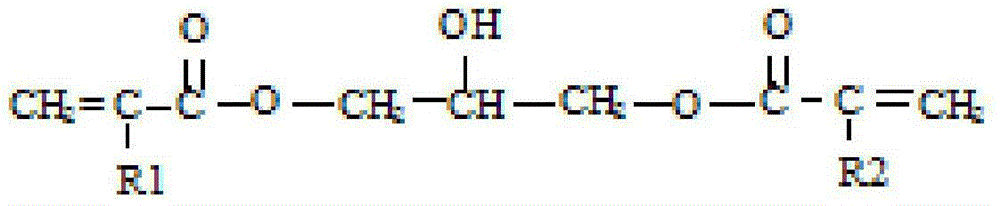

[0062] Based on the total mass of raw materials participating in inverse emulsion polymerization, the drag reducer emulsion was synthesized according to the following specific steps:

[0063] 1) Preparation of the water phase: Dissolve 40.17g of glyceryl dimethacrylate, 47.73g of allyltrimethylammonium chloride, and 25g of acrylamide in distilled water, add 0.15g of disodium EDTA, and add 0.045g of disodium EDTA before emulsification to trigger Agent V50, dissolved evenly.

[0064] 2) Preparation of the oil phase: Weigh 64g of white oil with a mass ratio of 20%, and emulsifiers Span-80 (4%, 12.8g), span85 (1%, 3.2g).

[0065] 3) Emulsification: add the water phase dropwise under the condition of Jingjing nitrogen (that is, nitrogen with a purity of 99.99%), the stirring speed is 2000r / min during the dropping, and the dropping time is 65-75min. After the dropwise addition, stir for 30 minutes.

[0066] 4) Reaction: control the heating rate, raise the temperature to 63-65° C.,...

Embodiment 2

[0071] Based on the total mass of raw materials participating in inverse emulsion polymerization, the drag reducer emulsion was synthesized according to the following specific steps:

[0072] 1) Preparation of the water phase: Dissolve 40.17g of glyceryl dimethacrylate, 23.87g of allyltrimethylammonium chloride, and 37.53g of acrylamide in distilled water, add 0.15g of disodium EDTA, and add 0.05g of it before emulsification Initiator V50, dissolves evenly.

[0073] 2) Preparation of the oil phase: Weigh 64g of white oil with a mass ratio of 20%, and emulsifiers Span-80 (4%, 12.8g), span85 (1%, 3.2g).

[0074] 3) Emulsification: add the water phase dropwise under the condition of nitrogen, the stirring speed is 2000r / min, and the dropping time is 65-75min. After the dropwise addition, stir for 30 minutes.

[0075] 4) Reaction: Control the heating rate, raise the temperature to 63-65°C, and stop the reaction after 4.5 hours.

[0076] Take 492.35ml of distilled water and plac...

Embodiment 3

[0080] Based on the total mass of raw materials participating in inverse emulsion polymerization, the drag reducer emulsion was synthesized according to the following specific steps:

[0081] 1) Preparation of the water phase: Dissolve 40.17g of glyceryl dimethacrylate, 73.11g of methacryloyloxyethyltrimethylammonium chloride, and 37.53g of acrylamide in distilled water, and add 0.15g of disodium EDTA to emulsify Before adding 0.53g initiator V50, dissolve evenly.

[0082] 2) Preparation of the oil phase: Weigh 64g of white oil with a mass ratio of 20%, and emulsifiers Span-80 (4%, 12.8g), span85 (1%, 3.2g).

[0083] 3) Emulsification: Circulate the oil phase, add the water phase dropwise under the condition of purifying nitrogen, the stirring speed is 2000r / min during the dropwise addition, the dropwise addition time is 65-75min, and stir for 30min after the dropwise addition is completed.

[0084] 4) Reaction: Control the heating rate, raise the temperature to 63-65°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com