Preparation method for super-hydrophobic aluminum surface

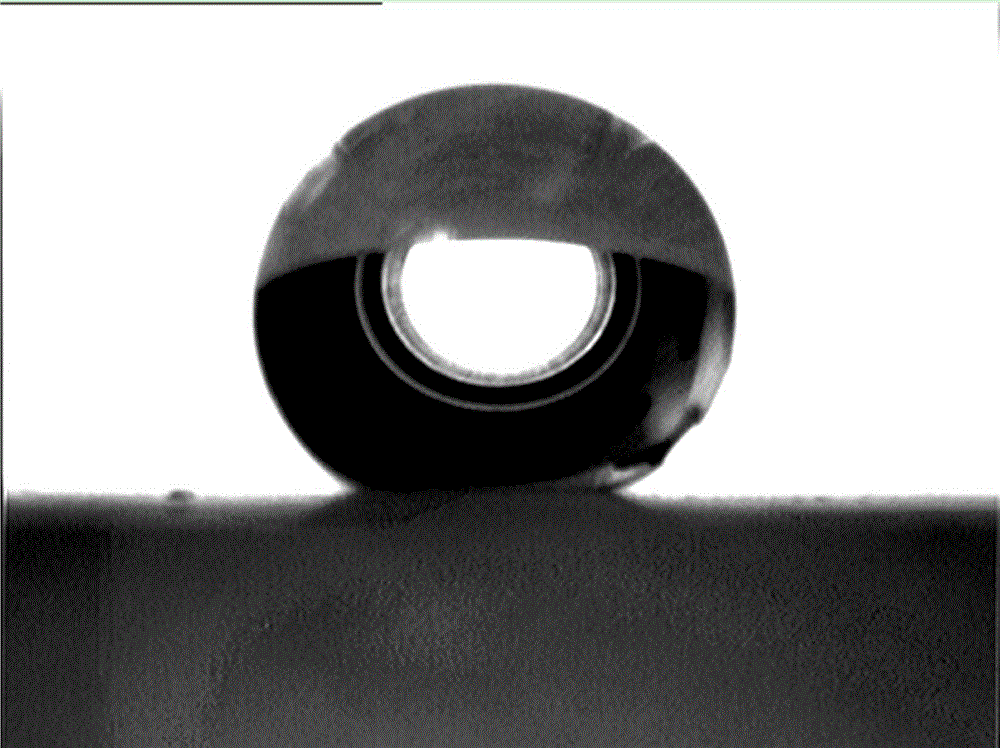

An aluminum surface, super-hydrophobic technology, applied in the direction of surface reaction electrolytic coating, gaseous chemical plating, anodic oxidation, etc., can solve the problems of wire galloping, broken wire, inverted rod, etc., and achieve high stability, cold resistance and moisture resistance Good, good hydrophobicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

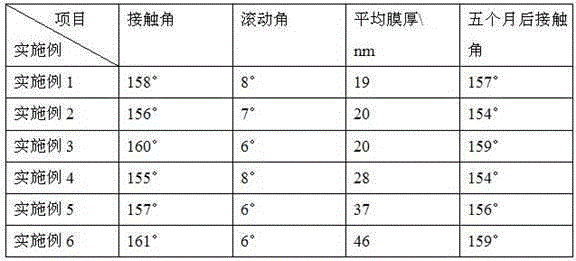

Embodiment 1

[0019] A preparation method for superhydrophobic aluminum surface, is characterized in that, comprises the following steps:

[0020] (4) Aluminum sheet pretreatment: select aluminum with a purity of 99.99%, prepare an aluminum sheet with a size of 2cm×1cm×1mm, and put it into 10wt% detergent aqueous solution, 95% ethanol solution and deionized aqueous solution in sequence. Ultrasonic cleaning, each ultrasonic cleaning time is 20min; then the aluminum sheet is put into the electrolytic polishing solution for polishing, and the polishing time is controlled at 8min; then the aluminum sheet is taken out, placed in a drying oven, and dried at 80°C.

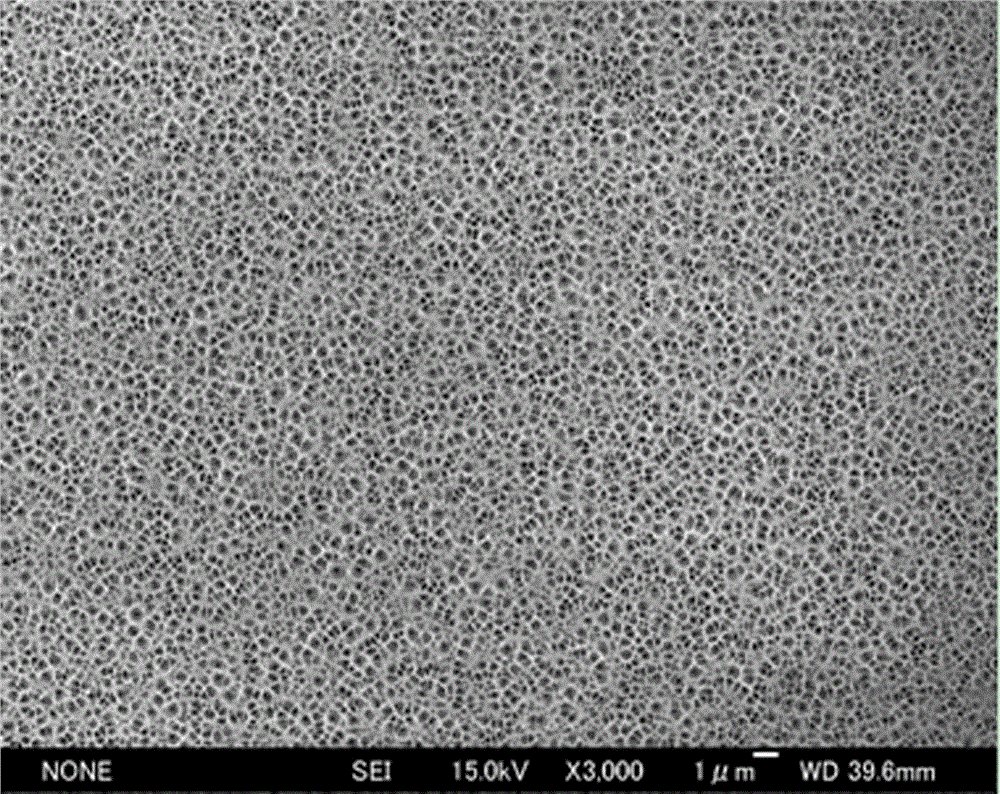

[0021] (5) Anodizing: Use the pretreated aluminum sheet as the anode, the graphite rod as the cathode, and the phosphoric acid solution with a concentration of 0.2M as the electrolyte. Put the electrolytic cell into a constant temperature water tank for electrolysis. The time is 1.5h, the voltage is 130V; after the electrolysis is comp...

Embodiment 2

[0028] A preparation method for superhydrophobic aluminum surface, is characterized in that, comprises the following steps:

[0029] (1) Aluminum sheet pretreatment: select aluminum with a purity of 99.99%, prepare an aluminum sheet of 2cm×1cm×1mm, put it into 10wt% detergent aqueous solution, 95% ethanol solution and deionized aqueous solution for ultrasonic cleaning, The ultrasonic cleaning time is 20 minutes each time; then the aluminum sheet is put into the electrolytic polishing solution for polishing treatment, and the polishing time is controlled at 8 minutes; then the aluminum sheet is taken out, placed in a drying oven, and dried at 80°C.

[0030] (2) Anodizing: Use the pretreated aluminum sheet as the anode, the graphite rod as the cathode, and the phosphoric acid solution with a concentration of 0.3M as the electrolyte. Put the electrolytic cell into a constant temperature water tank for electrolysis. The time is 1.5h, the voltage is 130V; after the electrolysis is ...

Embodiment 3

[0037] A preparation method for superhydrophobic aluminum surface, is characterized in that, comprises the following steps:

[0038] (1) Aluminum sheet pretreatment: select aluminum with a purity of 99.99%, prepare an aluminum sheet of 2cm×1cm×1mm, put it into 10wt% detergent aqueous solution, 95% ethanol solution and deionized aqueous solution for ultrasonic cleaning, The ultrasonic cleaning time is 20 minutes each time; then the aluminum sheet is put into the electrolytic polishing solution for polishing treatment, and the polishing time is controlled at 8 minutes; then the aluminum sheet is taken out, placed in a drying oven, and dried at 80°C.

[0039] (2) Anodizing: Use the pretreated aluminum sheet as the anode, the graphite rod as the cathode, and the phosphoric acid solution with a concentration of 0.4M as the electrolyte. Put the electrolytic cell in a constant temperature water tank for electrolysis. The time is 1.5h, the voltage is 130V; after the electrolysis is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com