Production method for refined hemp and regenerated cellulose fiber high-count blended yarn

A technology of regenerated cellulose and refined hemp, which is applied in spinning machines, textile material processing, yarn, etc., can solve the impact of product diversification and high-end, and it is difficult to achieve high count and high distribution of hemp regenerated cellulose fiber blended yarn , Restricting the healthy and rapid development of the hemp industry and other issues, to achieve the effect of strong improvement, improvement of production rate and quality, and improvement of spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 65% of the hemp fiber and 35% of the lyocell fiber adopt the production process method of the present invention, evenly spray a certain proportion of softening penetrating agent to the hemp fiber, carry out the treatment of moistening and oiling to the hemp fiber, then put the hemp fiber into The steam room controls the moisture regain of the hemp fiber treated by health care at 12-15%, softens the fiber, reduces the static electricity of the fiber, improves the spinnability of the fiber, and improves the production rate and quality of the product; through cleaning, carding, and Finally, the drawn roving is sent to the spinning frame that adopts the drafting of compact double aprons, and the roving is drafted, twisted and wound into a spun bobbin.

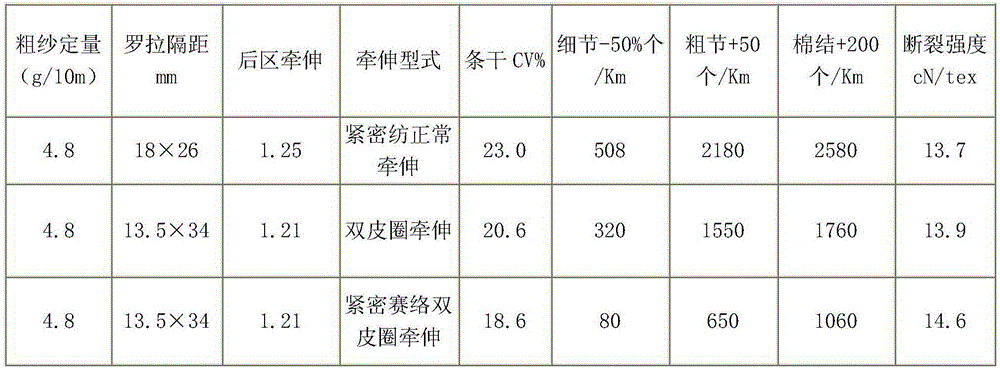

[0048] The spinning frame used in this embodiment is the FA506 spinning frame, wherein the technical requirements for the roving weight, the roller gauge of the spinning frame, the drafting multiple in the rear area, and the ...

Embodiment 2

[0052] 50% of the hemp fiber and 50% of the lyocell fiber adopt the production process of the present invention, evenly spray a certain proportion of softening penetrating agent to the hemp fiber, carry out the treatment of moistening and oiling to the hemp fiber, and then put the hemp fiber into The steam room controls the moisture regain of the hemp fiber treated by health care at 12-15%, softens the fiber, reduces the static electricity of the fiber, improves the spinnability of the fiber, and improves the production rate and quality of the product; through cleaning, carding, and Finally, the drawn roving is sent to the spinning frame that adopts the drafting of compact double aprons, and the roving is drafted, twisted and wound into a spun bobbin.

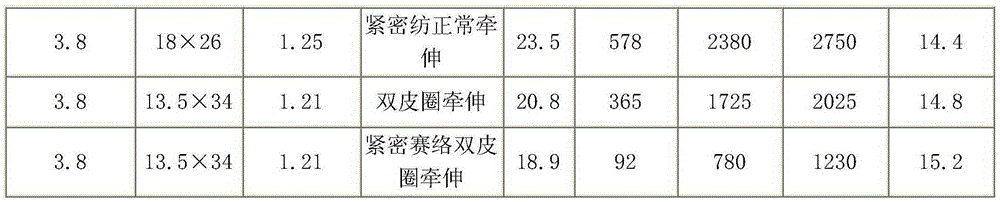

[0053] The spinning frame used in this embodiment is the FA506 spinning frame, wherein the technical requirements for the roving weight, the roller gauge of the spinning frame, the drafting multiple in the rear area, and the dra...

Embodiment 3

[0058] 55% of the hemp fiber and 45% of the lyocell fiber adopt the production process of the present invention, evenly spray a certain proportion of softening and penetrating agent to the hemp fiber, carry out the wetting and oiling treatment to the hemp fiber, and then put the hemp fiber into The steam room controls the moisture regain of the hemp fiber treated by health care at 12-15%, softens the fiber, reduces the static electricity of the fiber, improves the spinnability of the fiber, and improves the yield and quality of the product; through cleaning, carding, and Finally, the drawn roving is sent to the spinning frame that adopts the drafting of compact double aprons, and the roving is drafted, twisted and wound into a spun bobbin.

[0059] The spinning frame used in this embodiment is the FA506 spinning frame, wherein the technical requirements for the roving weight, the roller gauge of the spinning frame, the drafting multiple in the rear area, and the drafting form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com