Processing method of preserved low-sugar purple sweet potato

A processing method and technology of purple sweet potato, which are applied in the confectionery industry, confectionery, food ingredient functions and other directions, can solve the problems of not conforming to the health care concept, high sugar content and high sulfur content, and achieve products with high added value and rich nutrition. , the effect of eating convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for processing low-sugar preserved purple sweet potato, comprising the following steps:

[0033] (1) Material selection, cleaning, and cutting: choose purple sweet potatoes that are plump, free from mechanical damage, rotten, and insect-free, and rinse with clean water. Peel off the outer skin with a knife according to known methods, then cut into strips of 10cm*1cm*0.4cm.

[0034] (2) Color protection and hardening: Soak the purple potato strips in the color protection and hardening solution for 30 minutes, and then take out the dry water. Color protection hardening liquid formula (mass fraction): 0.05CaCl 2 +0.6% chlorogenic acid +0.05% citric acid +1.0% VC. The mass ratio of purple sweet potato to color-protecting hardening solution is 1:5 (g / g).

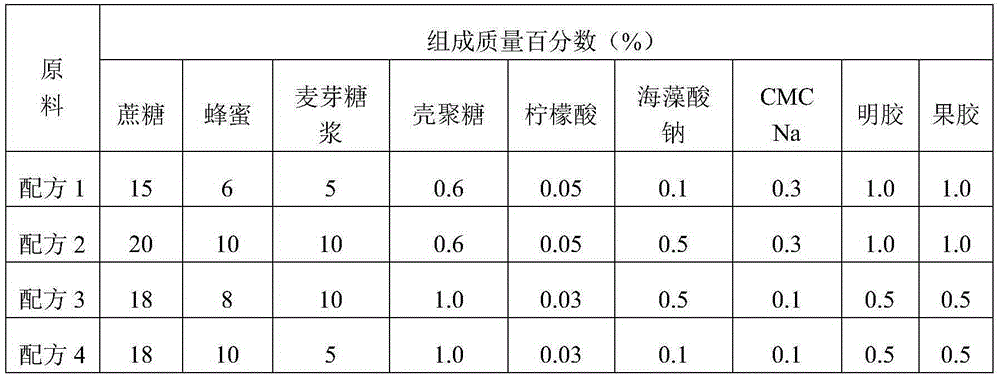

[0035] (3) Sugar infiltration promoting solution treatment: immerse the color-protected and hardened purple potato strips in the infiltration promoting solution for 30 minutes, and then remove and drain. The f...

Embodiment 2

[0040] A method for processing low-sugar preserved purple sweet potato, comprising the following steps:

[0041] (1) Material selection, cleaning, and cutting: choose purple sweet potatoes that are plump, free from mechanical damage, rotten, and insect-free, and rinse with clean water. Peel off the outer skin with a knife according to known methods, then cut into strips of 10cm*1cm*0.4cm.

[0042] (2) Color protection and hardening: Soak the purple potato strips in the color protection and hardening solution for 50 minutes, and then take out the dry water. Color protection hardening liquid formula (mass fraction): 1.0% CaCl 2 + 0.03% chlorogenic acid + 0.03% citric acid + 0.5% VC; the mass ratio of purple sweet potato to color-protecting hardening solution is 1:5 (g / g).

[0043] (3) Sugar infiltration promoting solution treatment: immerse the color-protected and hardened purple potato strips in the infiltration promoting solution for 90 minutes, and then remove and drain. T...

Embodiment 3

[0048] A method for processing low-sugar preserved purple sweet potato, comprising the following steps:

[0049] (1) Material selection, cleaning, and cutting: choose purple sweet potatoes that are plump, free from mechanical damage, rotten, and insect-free, and rinse with clean water. Peel off the outer skin with a knife according to known methods, then cut into strips of 10cm*1cm*0.4cm.

[0050] (2) Color protection and hardening: Soak the purple potato strips in the color protection and hardening solution for 30 minutes, and then take out the dry water. Color protection hardening liquid formula (mass fraction): 1.0% CaCl 2 +0.6% chlorogenic acid +0.03% citric acid +0.5% VC. The mass ratio of purple sweet potato to color-protecting hardening solution is 1:5 (g / g).

[0051] (3) Sugar infiltration promoting solution treatment: immerse the color-protected and hardened purple potato strips in the infiltration promoting solution for 30 minutes, and then remove and drain. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com