Milk favored paste used as dog food

A milk-flavored and dog food technology, applied in the field of pet food, can solve the problems of dog food that cannot be stressed by puppies, lack of meat flavor, etc., achieve balanced and comprehensive nutrition, improve recognition and love, and relieve stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

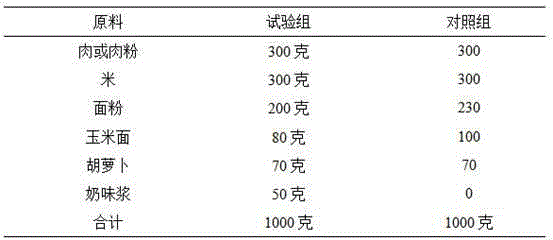

Image

Examples

Embodiment 1

[0015] A milk-flavored syrup for dog food, made of the following raw materials in parts by mass: 20 parts by mass of enzymatic cream, 60 parts of visceral reactants, and the rest of the raw materials are freely supplemented according to taste in the following ingredients: ethyl lactate 0.1-1, butyl lactate Lactone 1-5, milk lactone 0.5-2, diacetyl 0.1-0.5, isovaleric acid 0.1-0.3, butyl-octyl lactone 0.2-3, coconut aldehyde 0.1-2, butyl-octyl lactone 0.1-2 , Dodecanoic acid 0.5-4, C-decalactone 0.5-3.

[0016] The above-mentioned enzymatically hydrolyzed cream is prepared by the following steps: after mixing the cream and water, ultrasonically dissolving, pasteurize, adding lipase and flavor protease with a mass fraction of 1% each at 45°C, and performing enzymatic hydrolysis for 5 hours, Raise the temperature to 85°C and keep it for 30 minutes, and take the upper oil phase after standing still.

[0017] The above-mentioned visceral reactants are prepared through the followin...

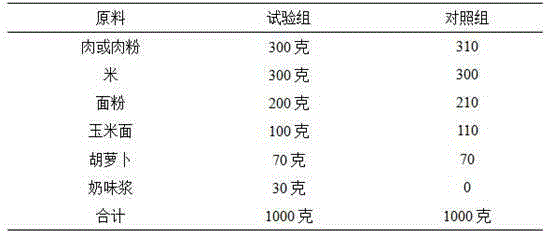

Embodiment 2

[0028] A milk-flavored syrup for dog food, made of the following raw materials in parts by mass, enzymatic cream 50, visceral reactants 35, and the rest of the raw materials are freely supplemented according to taste in the following ingredients: ethyl lactate 0.1-1, butyl lactate Lactone 1-5, milk lactone 0.5-2, diacetyl 0.1-0.5, isovaleric acid 0.1-0.3, butyl-octyl lactone 0.2-3, coconut aldehyde 0.1-2, butyl-octyl lactone 0.1-2 , Dodecanoic acid 0.5-4, C-decalactone 0.5-3.

[0029] The above-mentioned enzymatically hydrolyzed cream is prepared by the following steps: after mixing the cream and water, ultrasonically dissolving, pasteurize, adding lipase and flavor protease with a mass fraction of 1% each at 45°C, and performing enzymatic hydrolysis for 5 hours, Raise the temperature to 85°C and keep it for 30 minutes, and take the upper oil phase after standing still.

[0030] The above-mentioned visceral reactants are prepared through the following steps:

[0031] ⑴Taking...

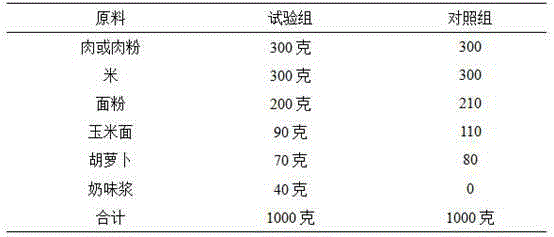

Embodiment 3

[0042] A milk-flavored syrup for dog food, made of the following raw materials in parts by mass, enzymatic cream 55, viscera reactant 30, and the rest of the raw materials are freely supplemented according to taste in the following ingredients: ethyl lactate 0.1-1, butyl lactate Lactone 1-5, milk lactone 0.5-2, diacetyl 0.1-0.5, isovaleric acid 0.1-0.3, butyl-octyl lactone 0.2-3, coconut aldehyde 0.1-2, butyl-octyl lactone 0.1-2 , Dodecanoic acid 0.5-4, C-decalactone 0.5-3.

[0043] The above-mentioned enzymatically hydrolyzed cream is prepared by the following steps: after mixing the cream and water, ultrasonically dissolving, pasteurize, adding lipase and flavor protease with a mass fraction of 1% each at 45°C, and performing enzymatic hydrolysis for 5 hours, Raise the temperature to 85°C and keep it for 30 minutes, and take the upper oil phase after standing still.

[0044] The above-mentioned visceral reactants are prepared through the following steps:

[0045] ⑴Taking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com