Method for quickly treating excrement wastewater in large-scale dairy farm

A dairy farm and manure technology, applied in the field of environmental engineering, can solve the problems of high operating costs, long treatment cycle, deep color, etc., and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

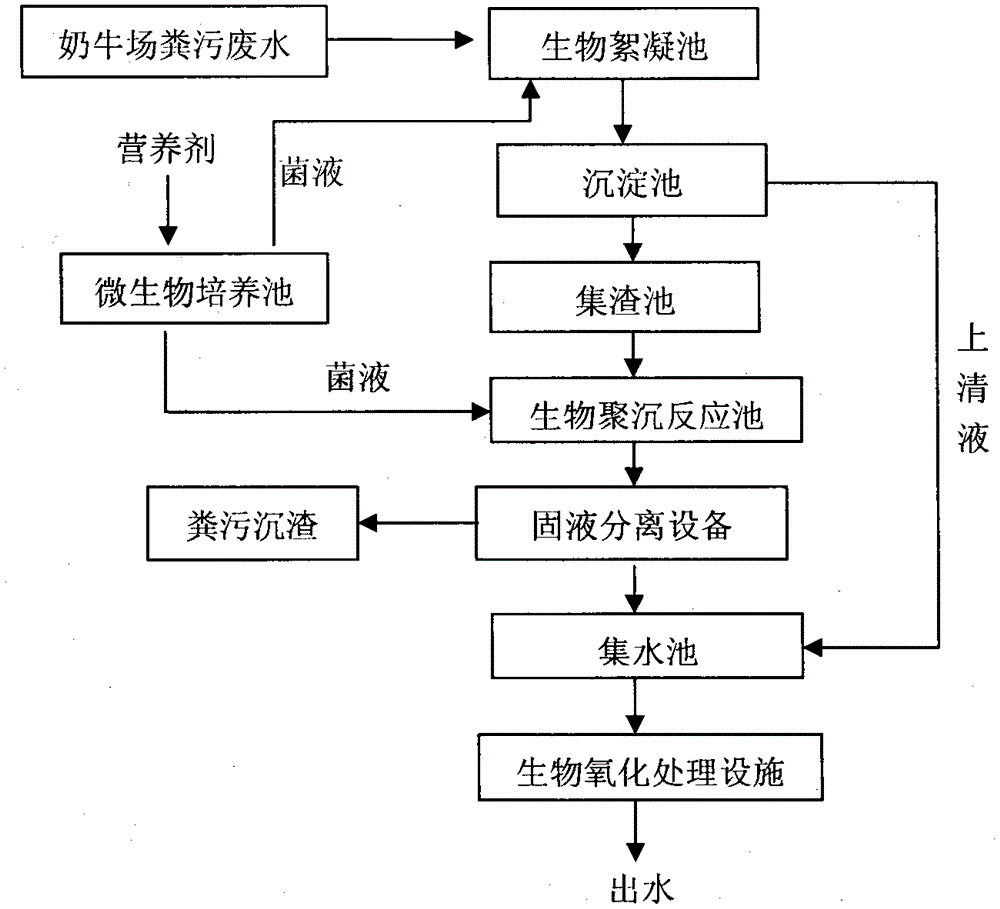

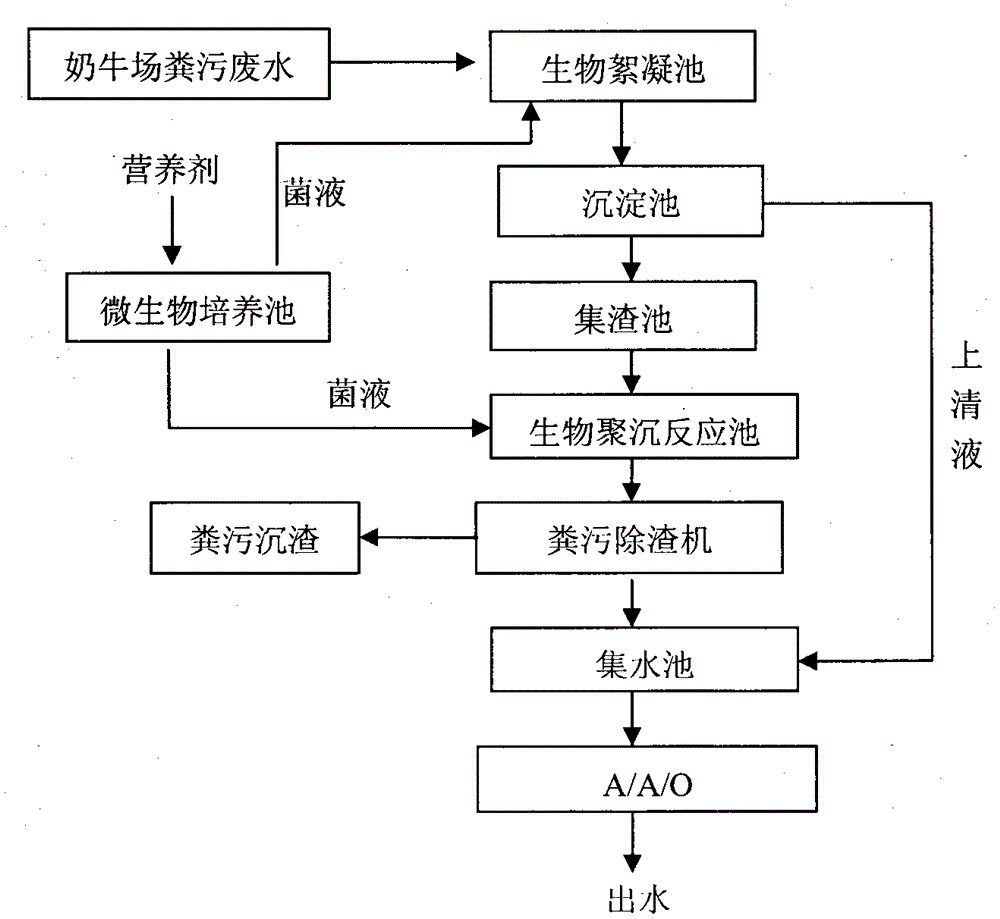

[0023] figure 2 It is a process flow chart of a large-scale dairy farm manure wastewater treatment method in the embodiment of the present invention. Such as figure 2 As shown, the method includes the following treatment facilities: biological flocculation tank, advection sedimentation tank, slag collection tank, biological coagulation reaction tank, chamber filter press, microbial culture tank, sump and nitrogen and phosphorus removal process (A / A / O).

[0024] In the biological flocculation tank, the fecal waste water of the dairy farm and the Klebsiella heterotrophic bacteria F1 in the microbial culture tank are fully mixed under the action of the mixer, and the Klebsiella heterotrophic bacteria F1 produces an efficient biological flocculant, which is mixed with the manure Particulate matter and colloidal substances in sewage and wastewater undergo flocculation and precipitation reactions. Fecal wastewater stays in the bioflocculation tank for 0.5h, and the effective v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com