Equipment and process for collecting and treating drilling waste without falling to the ground

A technology for drilling waste and treatment equipment, applied in mining wastewater treatment, sludge treatment, water/sewage treatment and other directions, can solve the problems of secondary pollution, large amount of curing agent, difficult transportation and cleaning, etc. Water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

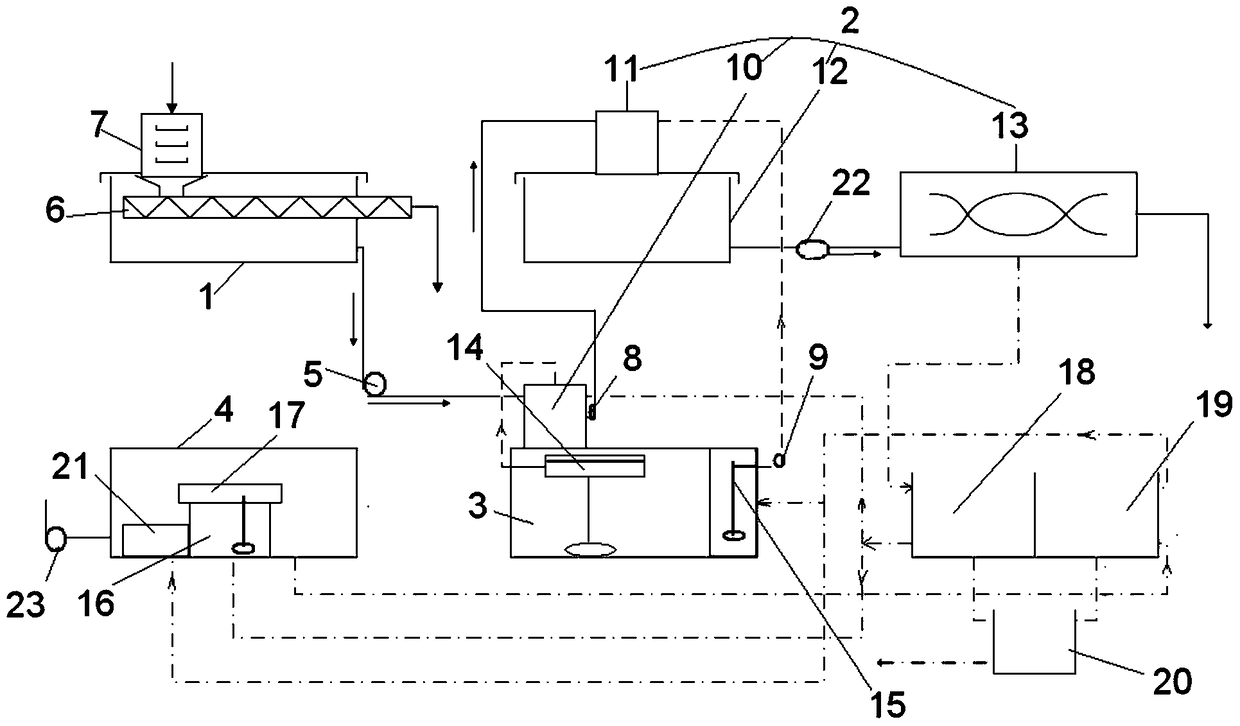

[0023] A non-landing collection and treatment equipment for drilling waste, including a drilling waste mud collection unit 1, a mud dewatering unit 2, a dosing unit 3, a water treatment and reuse unit 4; the drilling waste mud collection unit 1 includes a screw conveyor 6 And drying screen 7; the mud dewatering unit 2 includes a dilution and destabilizing tank 10, a sludge mixing tank 11, a sludge collection tank 12, and a sludge dewatering machine 13; the dosing unit 3 includes a gel breaker dosing device 14 , Flocculant dosing device 15; The water treatment and reuse unit 4 includes a coagulation sedimentation tank 16, an activated carbon adsorption tank 17, a dehydration buffer tank 18, a water reuse tank 19, an overflow liquid collection tank 20 and an ultrafiltration reactor Infiltration device 21; the upper part of the coagulation sedimentation tank 16 is connected to the activated carbon adsorption tank 17; the drilling waste mud collection unit 1 is connected to the dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com