Preparation method of hydrophobically associating polymer inverse emulsion

An inverse emulsion and hydrophobic association technology, which is applied in the field of preparation of hydrophobically associated polymer inverse emulsion, can solve the problems of slow dissolution process and complicated post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

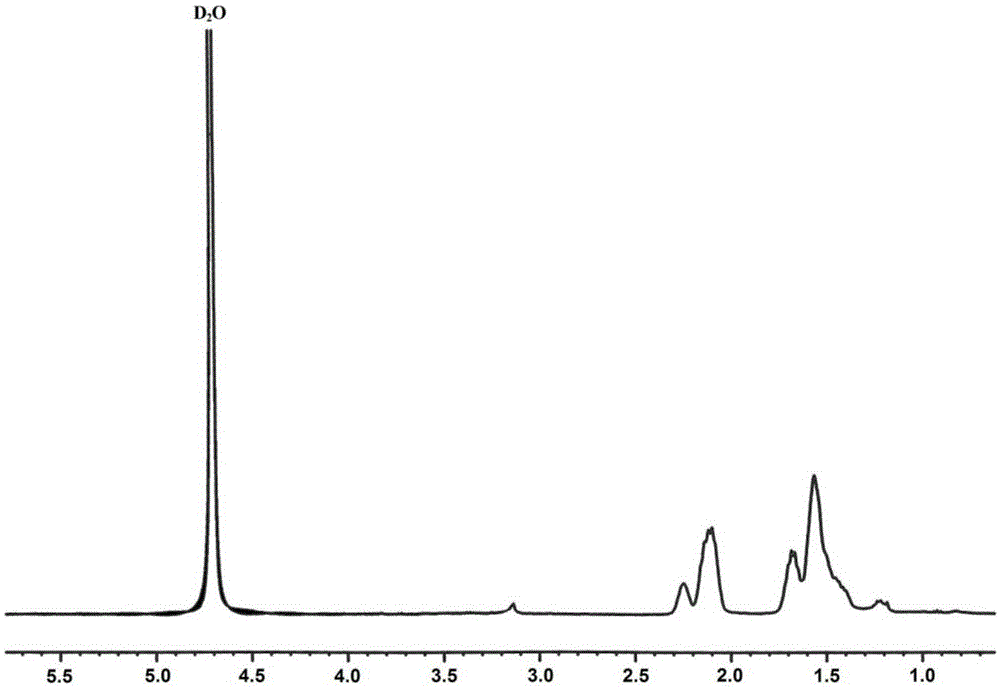

Image

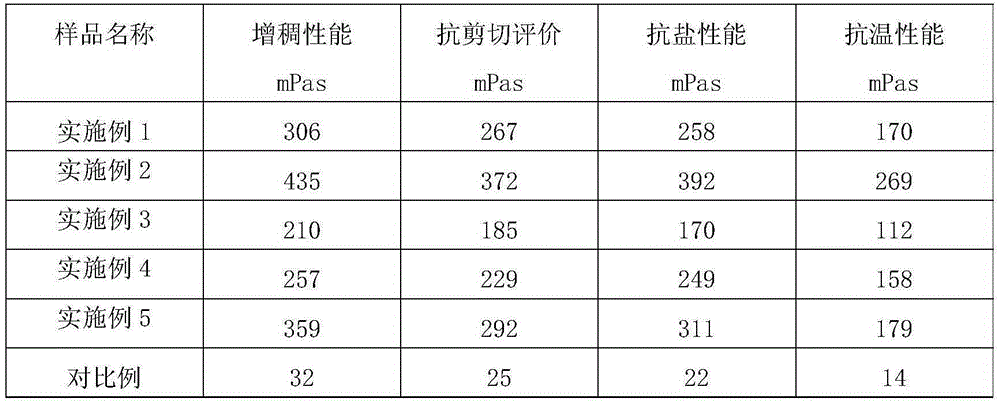

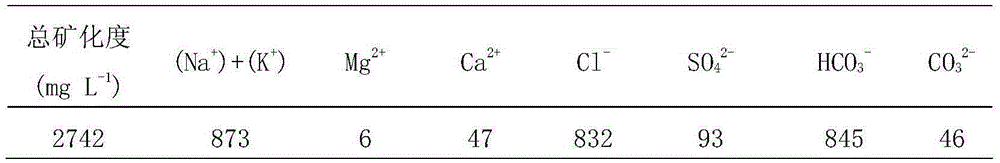

Examples

Embodiment Construction

[0010] Technical scheme of the present invention is as follows:

[0011] A preparation method for hydrophobically associated polymer inverse emulsion, comprising steps as follows:

[0012] (1) Oil phase

[0013] Dissolve emulsifiers Span80 and OP10 in white oil and stir evenly; the mass ratio of Span80 and OP10 is (20-8):1, and the amount of Span80 added is 1-8g dL relative to the total volume of the system -1 ;

[0014] (2) Water phase

[0015] Mix and dissolve hydrophobic monomers and water-soluble monomers in water at a mass ratio of 1: (10 to 500), and adjust the pH of the system by mixing the total mass of water-soluble monomers to water at a mass ratio of 1:5 to 1.5:1 value to 7~11, add cyclodextrin and reducing agent tetramethylethylenediamine (TMEDA), stir evenly, the mass ratio of cyclodextrin and hydrophobic monomer is (0.3~10):1; relative to the total volume of the system , the total amount of tetramethylethylenediamine added is 2.5~5.5mmol·L -1 ;

[0016] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com