Ordered mesoporous organosilicon fluorescent nanometer material and preparation method thereof

A fluorescent nanomaterial and mesoporous organosilicon technology, which is applied in the fields of chemistry and material science, can solve the problems of unsuitable application, limited application of fluorescent mesoporous nanoparticles, occupying space of pores, etc., and achieves the effect of good fluorescence tunability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

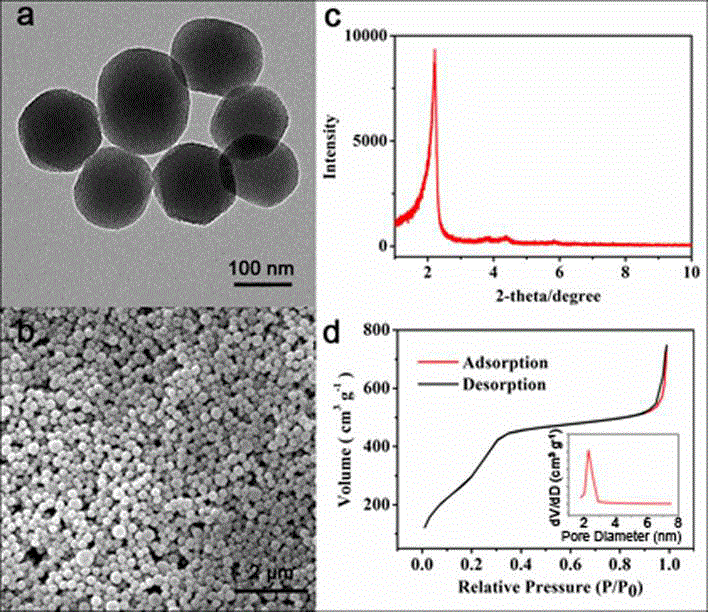

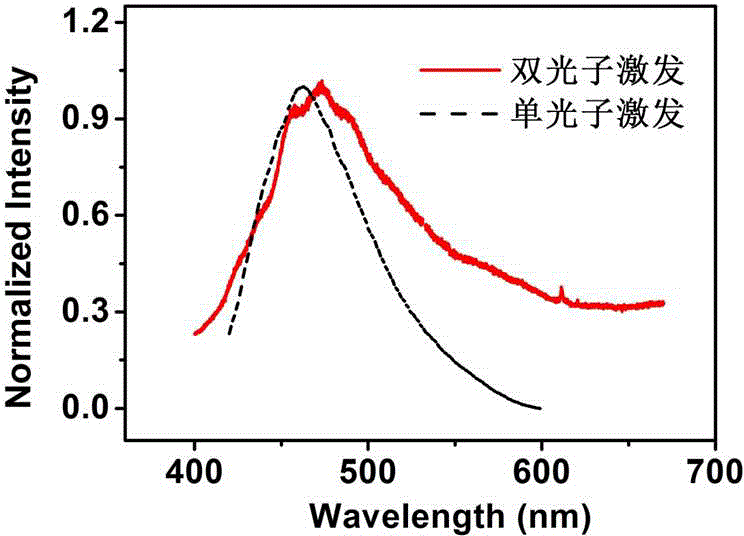

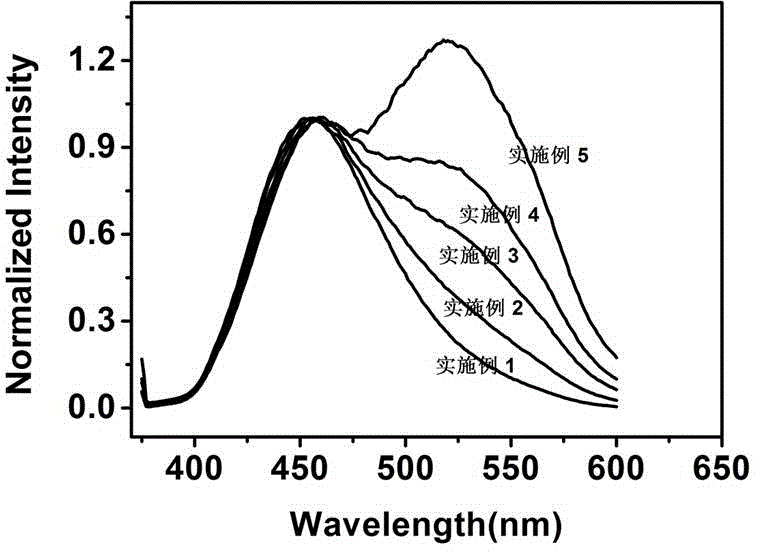

[0027] Measure 0.7ml of 2M sodium hydroxide aqueous solution, add 90ml of water to dilute, and stir evenly at 40°C; weigh 0.2g of dodecyltrimethylammonium bromide (CTAB), dissolve it in 10ml of water, and add it to the hydroxide In sodium aqueous solution, stir evenly; heat up to 70°C, after 10 minutes, add 1.0ml tetraethyl orthosilicate, 100ul carbon quantum dots (CD), after stirring for 2 minutes, add 1.0ml ethyl acetate, stir for 30 seconds, in Stand at 70°C for 2 hours; obtain a solid by centrifugation, wash with water and ethanol repeatedly, and dry. The surfactant is extracted and removed to obtain ordered mesoporous organic silicon fluorescent nanoparticles.

Embodiment 2

[0029] Measure 0.7ml of 2M sodium hydroxide aqueous solution, add 90ml of water to dilute, and stir evenly at 40°C; weigh 0.2g of dodecyltrimethylammonium bromide (CTAB), dissolve it in 10ml of water, and add it to the hydroxide In sodium aqueous solution, stir evenly; heat up to 70°C, after 10 minutes, add 1.0ml tetraethyl orthosilicate, 200ul carbon quantum dots (CD), after stirring for 2 minutes, add 1.0ml ethyl acetate, stir for 30 seconds, in Stand at 70°C for 2 hours; obtain a solid by centrifugation, wash with water and ethanol repeatedly, and dry. The surfactant is extracted and removed to obtain ordered mesoporous organic silicon fluorescent nanoparticles.

Embodiment 3

[0031] Measure 0.7ml of 2M sodium hydroxide aqueous solution, add 90ml of water to dilute, and stir evenly at 40°C; weigh 0.2g of dodecyltrimethylammonium bromide (CTAB), dissolve it in 10ml of water, and add it to the hydroxide In sodium aqueous solution, stir evenly; heat up to 70°C, after 10 minutes, add 1.0ml tetraethyl orthosilicate, 500ul carbon quantum dots (CD), after stirring for 2 minutes, add 1.0ml ethyl acetate, stir for 30 seconds, in Stand at 70°C for 2 hours; obtain a solid by centrifugation, wash with water and ethanol repeatedly, and dry. The surfactant is extracted and removed to obtain ordered mesoporous organic silicon fluorescent nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com