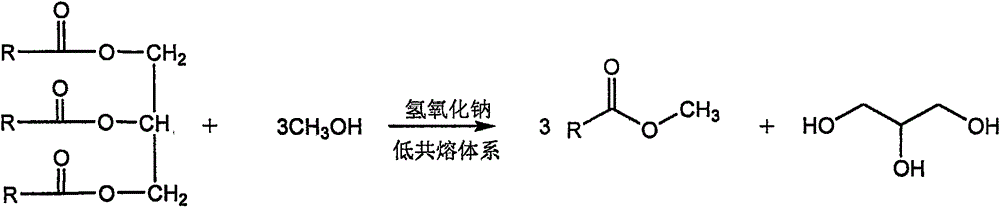

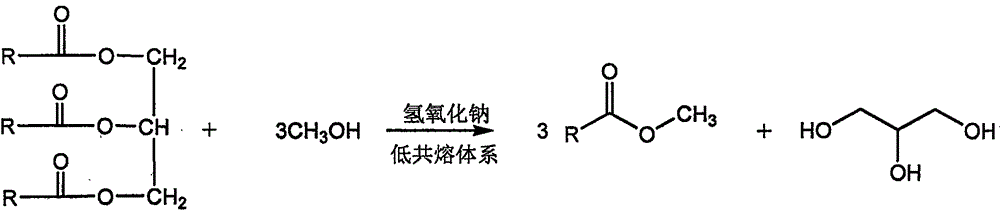

Method for synthesizing biodiesel in eutectic system

A biodiesel, synthetic biology technology, applied in biofuels, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of difficult separation and recovery, strong catalyst corrosion, secondary environmental pollution, etc., to reduce equipment and cost investment , The effect of simplifying the production process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In a 100mL three-necked round-bottomed flask, add 2.24g N-sulfonic acid propyl group-N, N, N-trihydroxyethylammonium, 0.76g glycerol (molar ratio is 1:1), 30g (0.034mol) soybean oil ( The average molecular weight is 878.25), heated in a water bath at 65°C for 10 minutes (to reduce the viscosity of vegetable oil), then added 0.3g (0.0075mol) NaOH, 6g methanol (0.1875mol), stirred and refluxed for 4.0 hours under normal pressure in a water bath at 65°C, and cooled to room temperature, transferred to a separatory funnel for stratification (rapid stratification), the lower layer is a mixture of excess methanol, glycerin, deep eutectic solvent, and NaOH; Drying under vacuum gave 25.7 g of pure product with a yield of about 85%.

Embodiment 2

[0031] In a 100mL three-necked round-bottomed flask, add 2.98g N-sulfonic acid propyl-N, N, N-trihydroxyethylammonium, 1.52g glycerol (molar ratio is 1:1), 30g (0.034mol) soybean oil ( Average molecular weight 878.25), heated under 65 ℃ water bath for 10 minutes, then added 0.15g of NaOH, 8.7g of methanol (0.27mol), 4.5g of deep eutectic solvent (N-sulfonic acid propyl-N, N, N-trihydroxy Ethylammonium / glycerol molar ratio is 1: 1.5), reflux reaction under normal pressure under 65°C water bath for 2.0 hours, cooled to room temperature, transferred to a separatory funnel for layering (rapid layering), the lower layer is excess methanol, glycerin , a mixture of deep eutectic solvent and NaOH; the upper layer is the product, after washing with hot water for 3 to 5 times, vacuum drying at 400 Pa and 80°C to obtain 26.0 g of the pure product, with a yield of about 86%.

Embodiment 3

[0033] In a 100mL three-necked round-bottomed flask, add 1.98g N-sulfonic acid propyl-N, N, N-trihydroxyethylammonium, 2.02g glycerin (molar ratio is 1:3), 30g soybean oil (average molecular weight 878.25) , heated in a water bath at 65°C for 10 minutes, then added 1.5g of NaOH, 8g of methanol, stirred and refluxed under normal pressure in a water bath at 65°C for 3.0 hours, cooled to room temperature, and transferred to a separatory funnel for layering (rapid layering), the lower layer was A mixture of excess methanol, glycerin, deep eutectic solvent, and NaOH; the upper layer is the product. After washing with hot water for 3 to 5 times, vacuum drying at 400 Pa and 80° C. gives 26.6 g of pure product, with a yield of about 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com