Manufacturing method for ultraviolet LED device

A technology for LED devices and manufacturing methods, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult airtight packaging, temperature limitation of welding process, affecting the performance and reliability of LED devices, etc., so as to improve airtightness, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

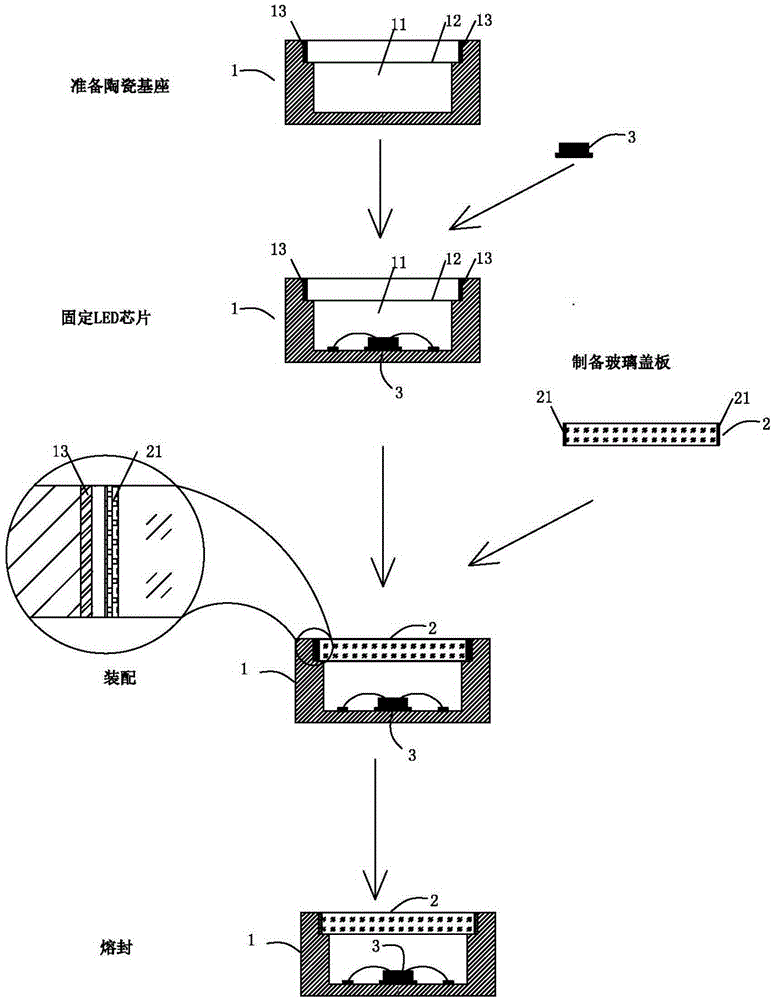

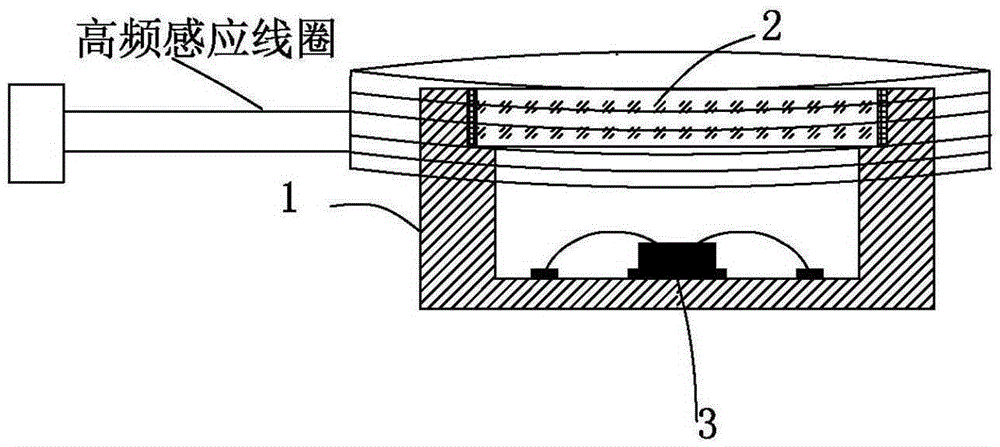

[0028] refer to figure 1 , a kind of manufacture method of ultraviolet LED device, comprises the following steps:

[0029] Prepare the ceramic base 1: the ceramic base 1 has a cavity 11, a groove 12 is arranged on the upper part of the cavity 11, and a metal layer 13 is formed on the side wall of the groove 12 by sputtering, evaporation or co-firing. The first metal layer 13 can be a copper film layer, a tin film layer or a silver film layer. The copper film layer, tin film layer and silver film layer mentioned here do not include the metal layer formed only by copper, tin or silver, but also include the film layer formed by the alloy mainly composed of copper, tin and silver. Preferably, the thickness of the first metal layer 13 is 10-30 μm, such as 10 μm, 20 μm, 25 μm, 30 μm and so on.

[0030] Fixing the LED chip 3: fixing the ultraviolet LED chip 3 on the bottom of the cavity 11 of the ceramic base 1 through crystal bonding and wire bonding processes.

[0031] Prepare t...

Embodiment approach 2

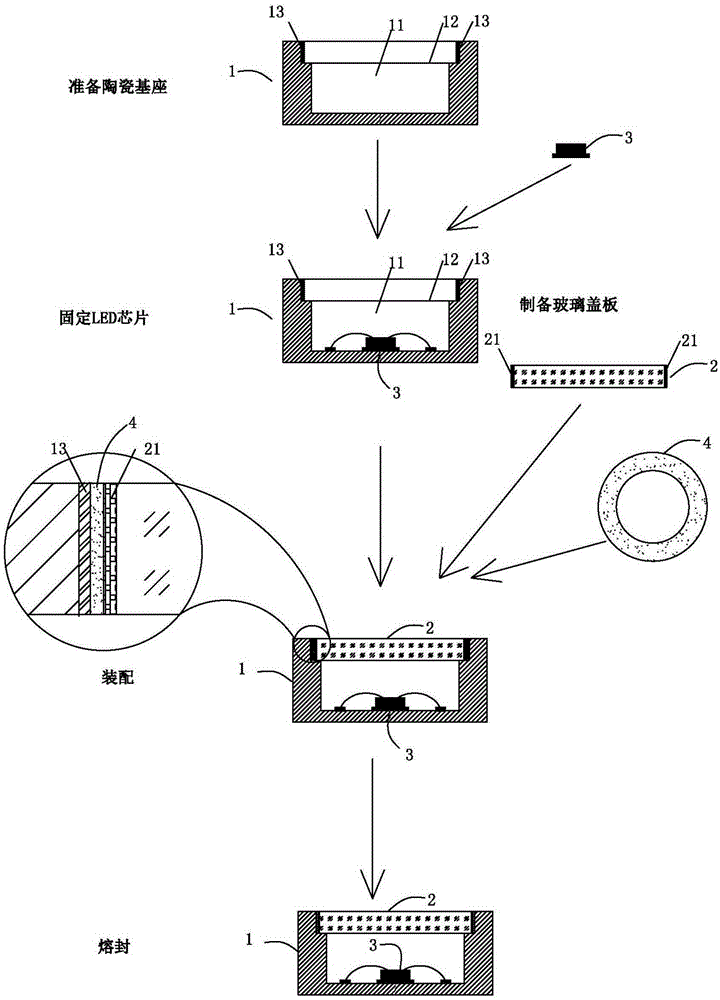

[0035] Or, as an improvement, in order to better realize fusion sealing, the manufacturing method of the present invention can refer to such as figure 2 The flowchart shown.

[0036] Prepare the ceramic base 1: the ceramic base 1 has a cavity 11, the upper part of the cavity 11 is provided with a groove 12, and the side wall of the groove 12 is provided with a metal layer 13 by sputtering, evaporation or co-firing; the metal layer 1 13 may be a copper film layer, a tin film layer or a silver film layer. The copper film layer, tin film layer and silver film layer mentioned here do not include the metal layer formed only by copper, tin or silver, but also include the film layer formed by the alloy mainly composed of copper, tin and silver. Preferably, the thickness of the first metal layer 13 is 10-30 μm, such as 10 μm, 20 μm, 25 μm, 30 μm and so on.

[0037] Fixing the LED chip 3: fixing the ultraviolet LED chip 3 on the bottom of the cavity 11 of the ceramic base 1 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com