Compound polymer electrolyte material, preparation method thereof, electrolyte membrane and all-solid-state lithium secondary battery

A technology of composite polymers and electrolyte materials, applied in the field of polymer electrolyte membranes, can solve problems such as low metal lithium stability and electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The present invention provides a method for preparing a composite polymer electrolyte material described in the above technical solution, comprising the following steps:

[0077] Mixing the polymer matrix, alkali metal salt, solvent and sulfide inorganic electrolyte to obtain a composite electrolyte solution;

[0078] The composite electrolyte solution is sequentially cast and dried to obtain a composite polymer electrolyte material.

[0079] The invention adopts solution casting method to prepare composite polymer electrolyte material.

[0080] The invention mixes polymer matrix, alkali metal salt, solvent and sulfide inorganic electrolyte to obtain composite electrolyte solution.

[0081] In the present invention, the type, source and amount of the polymer matrix, alkali metal salt and sulfide inorganic electrolyte are consistent with the type, source and amount of the polymer matrix, alkali metal salt and sulfide inorganic electrolyte described in the above technica...

Embodiment 1

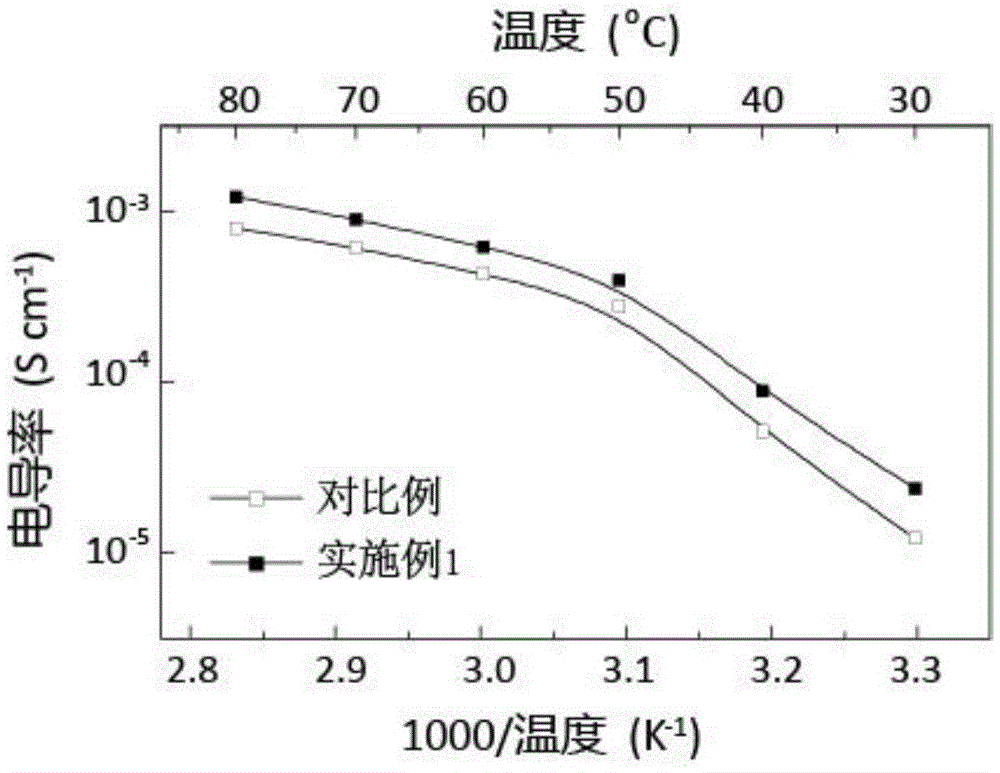

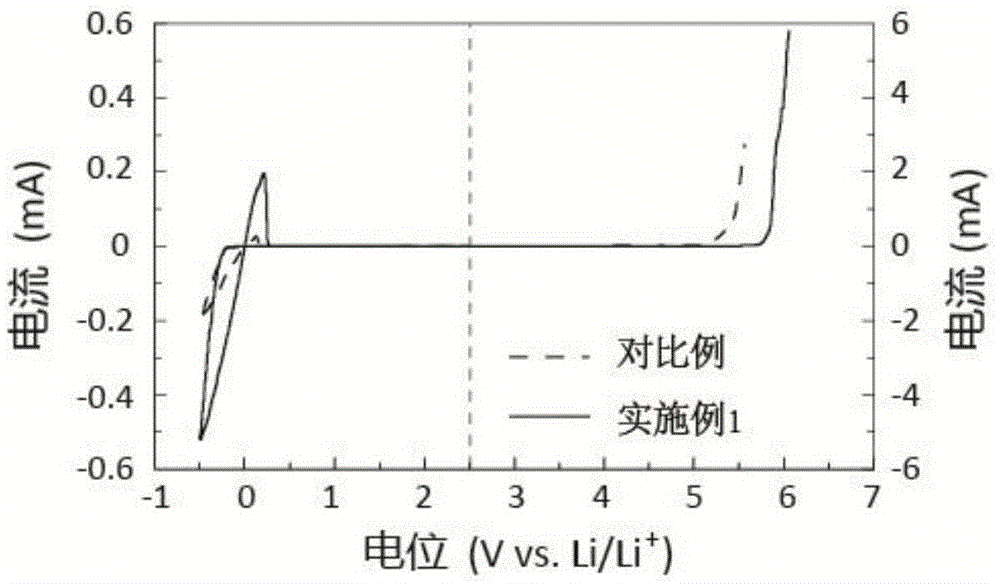

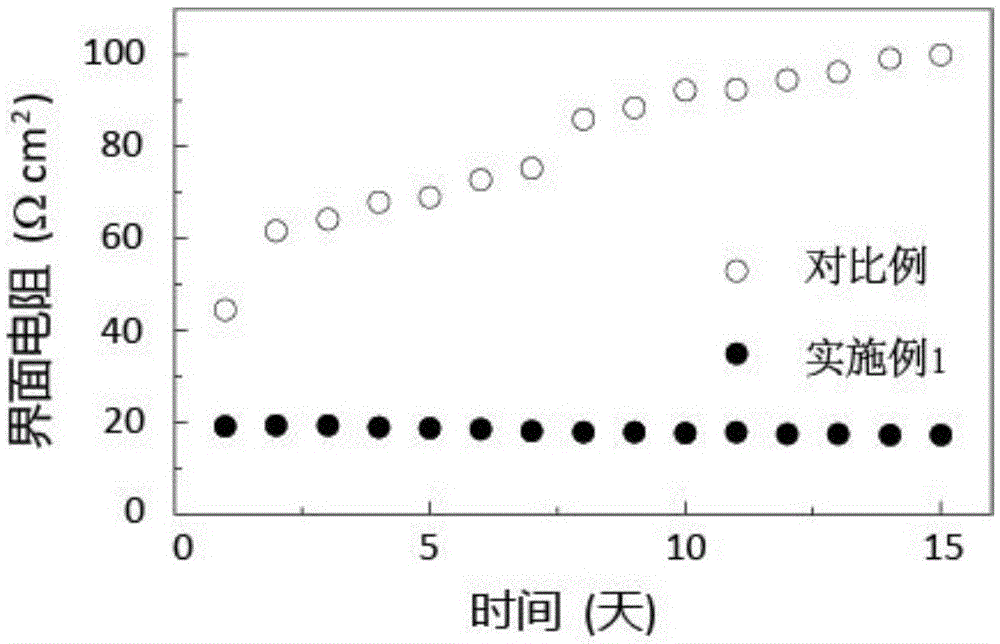

[0095] Under the protection of argon atmosphere, PEO and LiTFSI were weighed according to the EO / Li molar ratio of 18:1, stirred in acetonitrile (ACN), and after the stirring was uniform, 1% Li 10 GeP 2 S 12 , continue to stir to obtain a casting solution; cast the casting solution in a polytetrafluoroethylene mold, place it at room temperature for 24 hours to volatilize the solvent, and then place it in an oven at 50°C for 48 hours to completely volatilize the solvent to obtain a composite polymer electrolyte membrane . Using stainless steel as the blocking electrode, the electrochemical impedance spectroscopy (EIS) test was carried out at different temperatures to calculate its conductivity. The results are as follows: figure 1 as shown, figure 1 It is the conductivity spectrum of the organic / inorganic composite electrolyte membranes prepared in Example 1 and Comparative Example of the present invention as a function of temperature. From figure 1 It can be seen that the...

Embodiment 2

[0097] Under the protection of argon atmosphere, PEO and LiTFSI were weighed according to the EO / Li molar ratio of 15:1, stirred in tetrahydrofuran (THF), and after the stirring was uniform, 1% Li 2 S-P 2 S 5 -P 2 o 5 (70:29:1), continue stirring to obtain a casting solution; cast the casting solution in a polytetrafluoroethylene mold, place it at room temperature for 24 hours to evaporate the solvent, and then dry it in an oven at 50°C for 48 hours to completely evaporate the solvent , to obtain a composite polymer electrolyte membrane. Using stainless steel as the blocking electrode, EIS tests were carried out at different temperatures to calculate its conductivity. The results are as follows: Figure 6 as shown, Figure 6 It is the conductivity spectrum of the composite polymer electrolyte membrane prepared in Example 2 of the present invention as a function of temperature. From Figure 6 It can be seen that the ionic conductivity of this system is 9.09×10 at 80°C -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com