High-power femtosecond fiber laser device

A high-power, laser technology, used in lasers, laser components, phonon exciters, etc., can solve problems such as gaps in overall performance and stability, and achieve suppression of nonlinear effects, system simplicity, and strong tolerance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

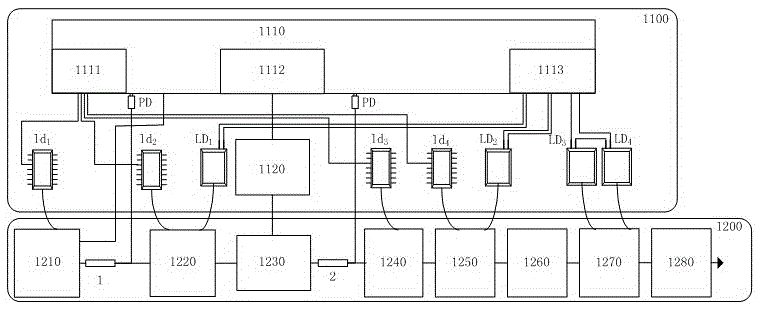

[0054] refer to figure 1 , The central wavelength of the spectrum of the high-power fiber laser of the present invention is 1064nm, the pulse repetition frequency is 500kHz, the average power is 10W, the single pulse energy is 20μJ, the pulse width is <500fs, and the pulse peak power is 40MW.

[0055] The laser includes a circuit part 1100 and an optical path part 1200 .

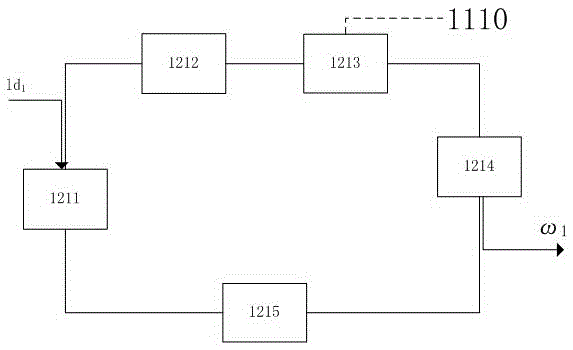

[0056] The circuit part 1100 is composed of a circuit board 1110, an acousto-optic modulation driver 1120 and 8 pumping sources. The circuit board 1110 is powered by an external power supply. A low-power pump control module 1111 and an acousto-optic modulation driver are fixed on the circuit board 1110. The control module 1112 and the high-power pump control module 1113, the acousto-optic modulation driver control module 1112 is connected to the acousto-optic modulation driver 1120; the low-power pump control module 1111 is connected to four low-power pumps ld 1 、ld 2 、ld 3 and ld 4 ; High-power pump con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com