Acid, alkali and organic solvent resisting diaphragm material, and preparation method and application thereof

A technology resistant to organic solvents and diaphragm materials, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high cost of membrane materials, narrow range of acid and alkali resistance and solvent resistance, and meet separation requirements. The effect of maintaining hydrophilicity and preventing the decrease of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

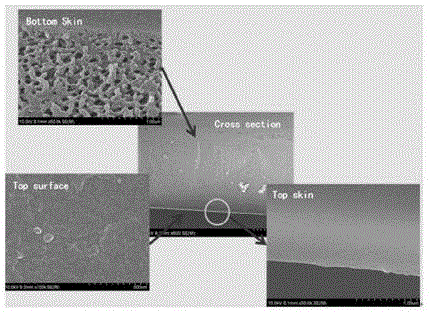

[0042] Prepare a homogeneous, clear casting solution as follows: 25 grams of methylisopropylene-propenyl alcohol copolymer (wherein the propenyl alcohol content is 45%) is dissolved in 75 grams of N-methylpyrrolidone, heated at 80 ° C, Stir for 12 hours until it reaches a uniform, colorless and clear state, the viscosity of the casting solution is 10000cp, and let it stand for defoaming. At an ambient temperature of 25°C and a relative humidity of 60%, the casting solution was scraped with a 200 μm scraper to form a nascent film, and then quickly immersed in a water bath at 20°C to solidify to form a film. After washing with water, 30% ethylene glycol is used for moisturizing treatment, and LiCl / water of 0.1mol / L is used as the raw material solution for Li + Ion diffusion test, the diffusion rate is 1.76*10 -8 mol cm -2 ·s -1 . The scanning electron micrograph of the prepared separator material is shown in figure 1 . figure 1 The crosssection in means: section; topsurfac...

Embodiment 2

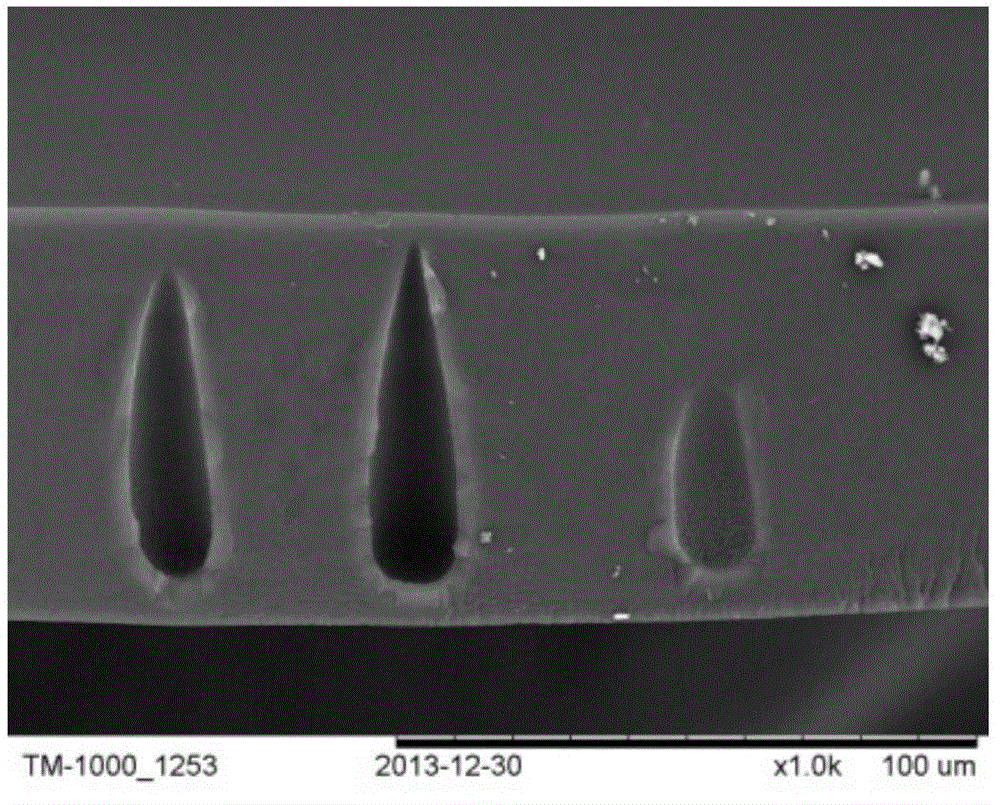

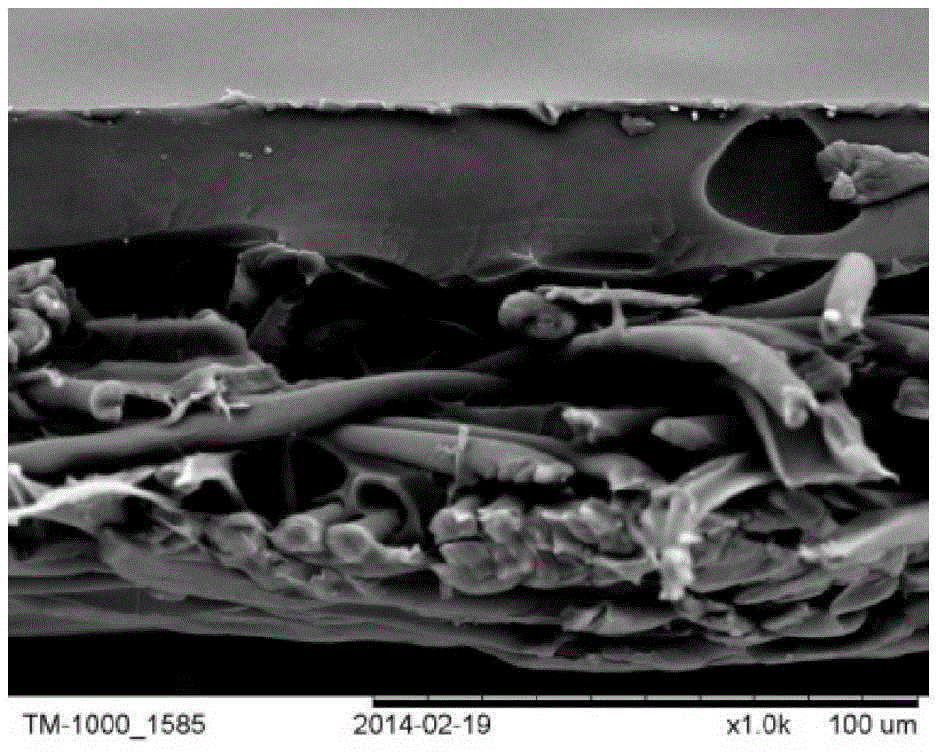

[0044] A homogeneous, clear casting solution was prepared as follows: 22 grams of ethylene-acrylic acid copolymer (wherein the ethylene content was 50%) was dissolved in 78 grams of dimethyl sulfoxide, allowed to stand for 6 hours for defoaming, and the ambient temperature was 25 ℃, humidity 60%, scrape the obtained homogeneous film casting solution on the 54um non-woven support layer with a 100μm scraper to form a nascent film with support, and quickly immerse it in a 3.5℃ gel bath to solidify and form a film. After washing with water, 30% glycerin was used for moisturizing treatment, thereby preparing a flat diaphragm material. see figure 2 with image 3 , are the cross-sectional topography of the flat diaphragm material and the cross-sectional topography of the non-woven support section, respectively. As shown in the figure, the thickness of the prepared film was 70.2 μm, and 0.1mol / LLiCl / water was used as the raw material solution for Li + Ion diffusion test, the diffu...

Embodiment 3

[0046] Prepare a homogeneous and clear casting solution as follows: Dissolve 30 grams of ethylene-vinyl alcohol copolymer with an ethylene content of 38% at 100°C in 70 grams of N,N-dimethylacetamide, seal and let stand Degassing for 6 hours, at an ambient temperature of 18.1°C and a humidity of 55%, scrape the obtained homogeneous film casting solution on a glass plate with a 200 μm scraper to form a nascent film, and quickly immerse it in a gel bath at 1.5°C to solidify and form a film , 25% polyethylene glycol moisturizing treatment after washing with water, thus obtaining the final product. The thickness of the prepared film is 102.5 μm, 0.1mol / LLiCl / water is used as the raw material solution for Li+ ion diffusion test, and the diffusion rate is 1.97*10 -8 mol cm -2 ·s -1 , with 0.1035mol / LLiCl+1.0mol / LNaOH as the water phase, 0.4mol / LHA+0.2mol / LQCl in the organic phase (wherein, HA and QCl refer to 1-phenylazo-2-naphthol and methyl Trioctylammonium chloride) is the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com