Click preparation and application of allyl cationic cyclodextrin chiral resolution material

A technology of chiral resolution and allyl cation, applied in separation methods, solid adsorbent liquid separation, other chemical processes, etc., can solve the problem of difficulty in ensuring the stability of chromatographic separation conditions and finding multiple chiral recognition sites Bonding arms and other problems, to achieve excellent splitting ability, reduce the difficulty of immobilization, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

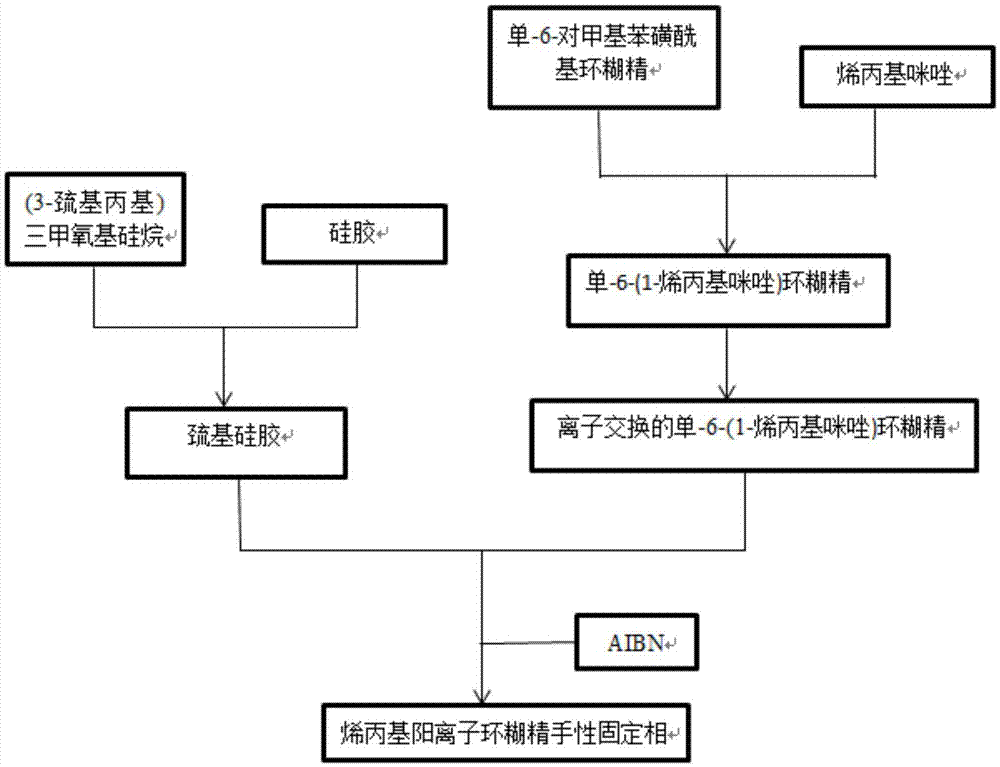

[0031] Such as figure 1 Shown in the present invention, the click preparation method of allyl cationic cyclodextrin chiral resolution material, the steps are as follows:

[0032] Step 1, the preparation of mono-6-(1-allylimidazole) cyclodextrin:

[0033]Add mono-6-p-toluenesulfonyl cyclodextrin and 1-allylimidazole in an organic solvent, and the organic solution used is toluene, ethanol, acetonitrile, pyridine, N,N-dimethylformamide (DMF ), one of dimethyl sulfoxide. The mono-6-p-toluenesulfonyl cyclodextrins used were mono-6-p-toluenesulfonyl-α-cyclodextrin, mono-6-p-toluenesulfonyl-β-cyclodextrin and One of the mono-6-p-toluenesulfonyl-γ-cyclodextrins. The molar ratio of the mono-6-p-methylbenzenesulfonyl cyclodextrin to 1-allylimidazole is 1:2 to 1:5, react at 50 to 150°C for 20 to 40 hours, and then the reaction system Pour into acetonitrile to precipitate a solid, wash twice with acetonitrile, and dry to obtain mono-6-(1-allylimidazole) cyclodextrin.

[0034] The str...

Embodiment 1

[0050] 5 g of mono-6-p-toluenesulfonyl-β-cyclodextrin, 20 mL of DMF and 2 mL of 1-allylimidazole were successively added into a 100 mL three-necked flask, and the reaction was stirred at 90° C. for 36 hours. Acetonitrile was added, and a large amount of white solid was precipitated, which was filtered by suction and dried in vacuum at 60° C. for 3 hours. Mono-6-(1-allylimidazole)-β-cyclodextrin was obtained.

[0051] Dissolve mono-6-(1-allylimidazolium)-β-cyclodextrin in a 300mL beaker, install the chloride-type anion resin in an ion-exchange column, and wash it with water continuously until the resin is neutral. The mono-6-(1-allylimidazole)-β-cyclodextrin solution was poured into an ion exchange column, rinsed continuously with a large amount of water, and the obtained filtrate was spin-dried with a rotary evaporator to obtain the product.

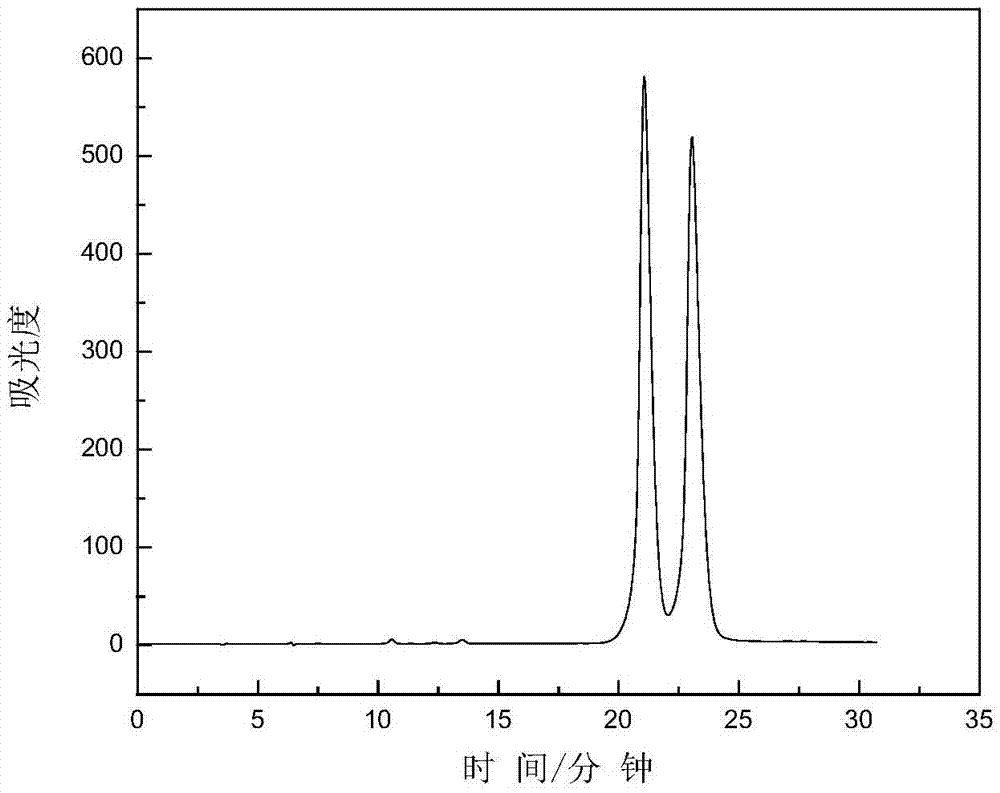

[0052] Add 2.94g silica gel, 30mL anhydrous toluene (CaH 2 dry), 0.75mL (3-mercaptopropyl)trimethoxysilane, reflux at 120°C for 8 hou...

Embodiment 2

[0057] Add 10.5g of mono-6-p-toluenesulfonyl-β-cyclodextrin, 15mL of DMF and 3.5mL of 1-allylimidazole into a 250mL three-necked flask in sequence, and stir at 80°C for 24 hours. Acetonitrile was added, and a large amount of white solid was precipitated, which was filtered by suction and dried in vacuum at 60° C. for 3 hours. Mono-6-(1-allylimidazole)-β-cyclodextrin was obtained.

[0058] Dissolve mono-6-(1-allylimidazole)-β-cyclodextrin in a 100mL beaker, install the nitrate anion resin in an ion exchange column, and wash it with water continuously until the resin is neutral. The mono-6-(1-allylimidazole)-β-cyclodextrin solution was poured into an ion exchange column, rinsed continuously with a large amount of water, and the obtained filtrate was spin-dried with a rotary evaporator to obtain the product.

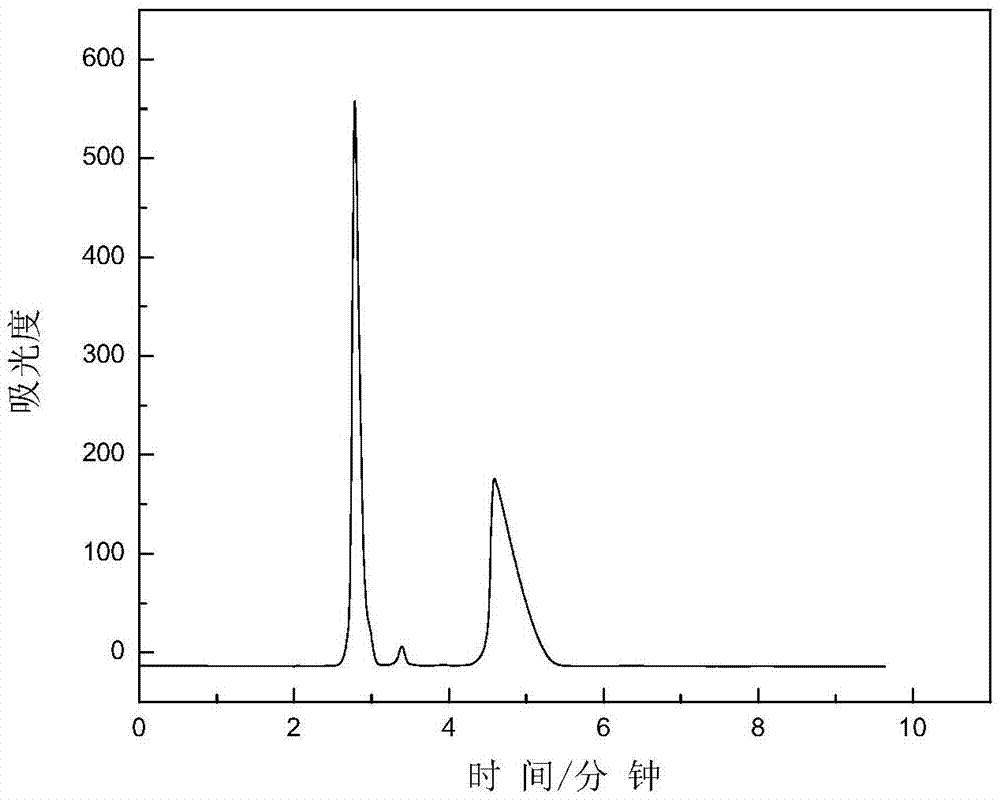

[0059] Add 2.94g of microspherical silica gel, 30mL of anhydrous toluene (CaH 2 dry), 0.75mL (3-mercaptopropyl)trimethoxysilane, reflux at 120°C for 8 hours. Filter, was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com