Automatic welding process for Invar die steel

A technology of automatic welding and mold steel, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems that the production and application have not been fully promoted, and achieve the purpose of overcoming poor fusion between layers, shortening the teaching time before welding, and reducing angular deformation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

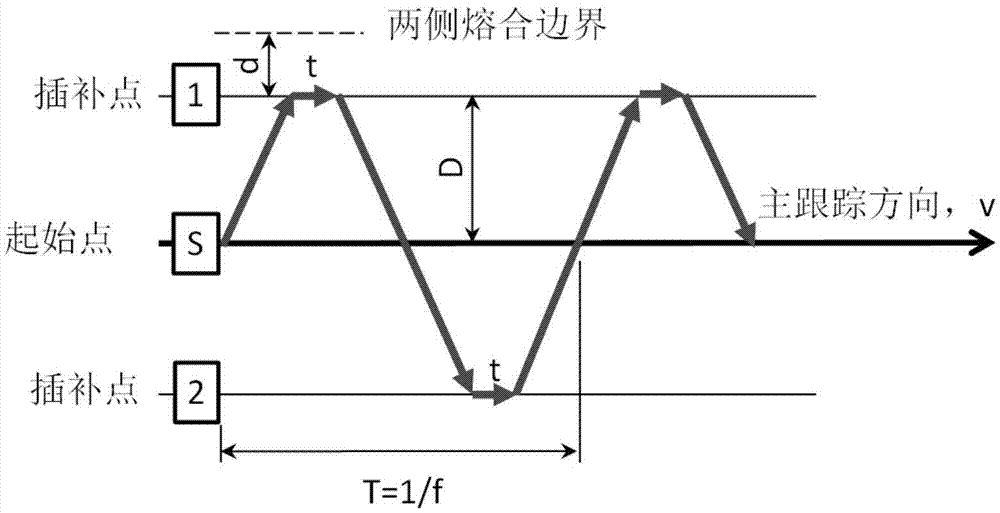

Method used

Image

Examples

Embodiment 1

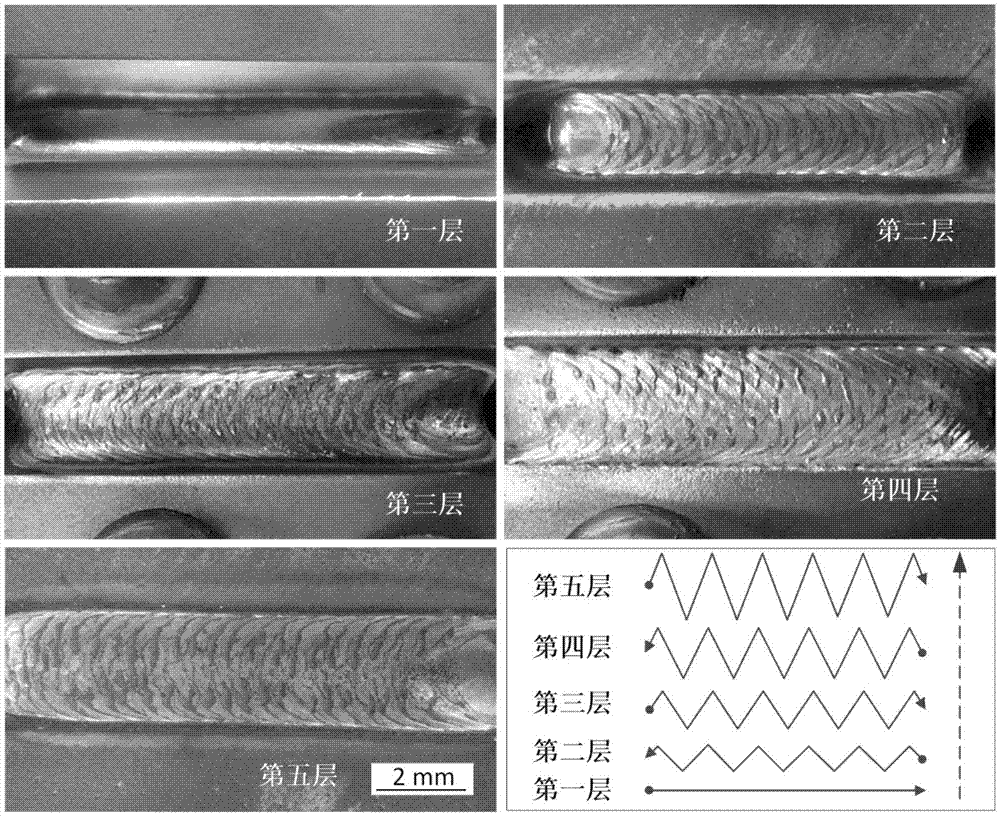

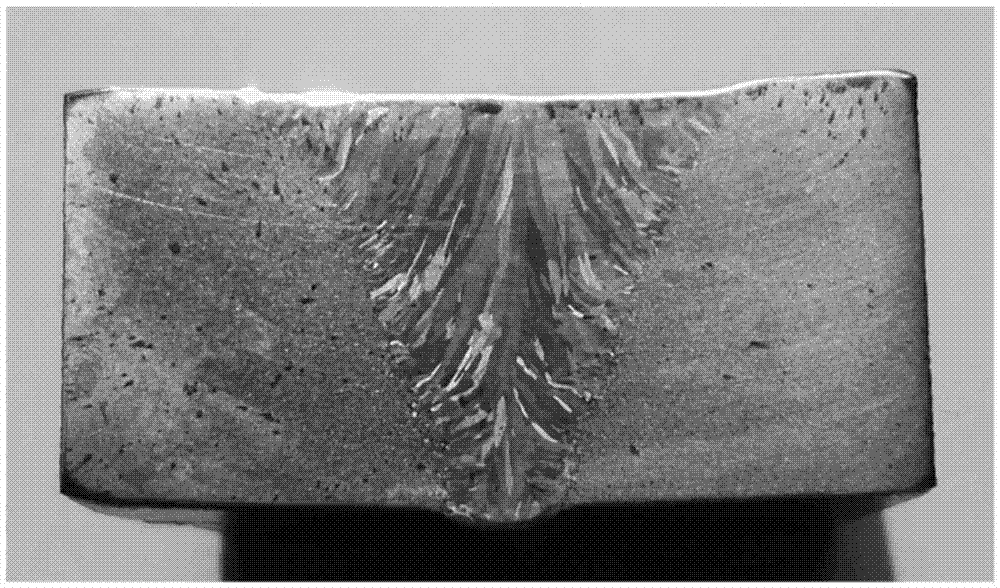

[0032] The welding base material is Invar steel with a Ni content of 35.67%, with a size of 100mm×50mm×19.05mm, a 60° groove, a blunt edge thickness of 1mm, and a spacing of 1.8mm; the welding wire is InvarM93, with a Ni content of 36.20%, and a diameter of 1.2mm. Flexible clamping is adopted, the reserved anti-deformation angle is 2°, and the flow rate of argon-rich atmosphere is 18L / min; the welding equipment is TAWERS-1400 integrated welding special robot produced by Tangshan Panasonic, the welding torch is perpendicular to the workpiece to be welded, and DC positive connection is adopted; Before welding, grind the groove of the workpiece and wipe it with acetone to remove the oxide film and impurities on the surface; after that, teach the welding track and set the parameters. The specific parameters are as follows:

[0033] ●The first layer: straight track, welding current 235A, welding voltage 26.3V, speed 0.35m / min;

[0034] ●Second layer: simple low-speed swing trajecto...

Embodiment 2

[0042] The welding base material is Invar steel with a Ni content of 35.67%, with a size of 250mm×250mm×19.05mm, a 60° groove, a blunt edge thickness of 1mm, and a spacing of 1.6mm; the welding wire is InvarM93, with a Ni content of 36.20%, and a diameter of 1.2mm. Flexible clamping is adopted, the reserved anti-deformation angle is 1.8°, and the flow rate of argon-rich atmosphere is 18L / min; the welding equipment is TAWERS-1400 integrated welding special robot produced by Tangshan Panasonic, the welding wire is tilted forward by 10°, and DC positive connection is adopted; welding The left and right directions alternate with each other; before welding, the groove of the workpiece is polished and wiped with acetone to remove the surface oxide film and impurities; after that, the teaching of the welding track and the setting of parameters are carried out. The specific parameters are:

[0043] ●The first layer: straight track, welding current 240A, welding voltage 27.3V, speed 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com