Method and device for preparing sodium chlorite through comprehensive method chlorine dioxide process

A technology of chlorine dioxide and sodium chlorite, which is applied in the direction of chlorine oxide and chlorous acid, can solve the problems of by-product neutral thenardite discharge, waste acid discharge, and low investment, and achieve long-term production economic benefits and strong market competition power and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

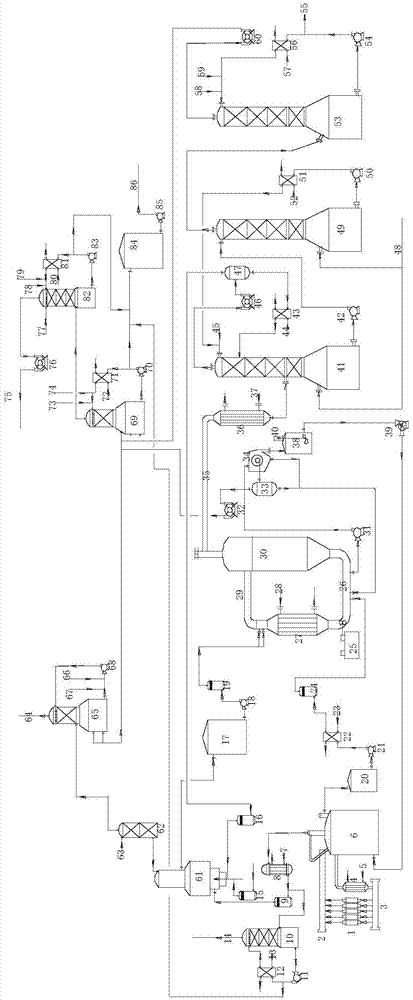

[0024] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

[0025] refer to figure 1 , the present invention prepares sodium chlorite technique with comprehensive method chlorine dioxide mainly by sodium chlorate (NaClO 3 ) electrolysis unit, hydrochloric acid (HCl) synthesis unit, chlorine dioxide (ClO 2 ) preparation unit, and sodium chlorite (NaClO 2 ) preparation unit, and a tail gas treatment unit is added at the same time. The reaction principles of the first four units are as follows:

[0026] (1) Sodium chlorate electrolysis: NaCl+3H 2 O→NaClO 3 +3H 2

[0027] (2) Synthesis of hydrochloric acid: H 2 +Cl 2 →2HCl

[0028] (3) Preparation of chlorine dioxide: NaClO 3 +2HCl→NaCl+ClO 2 +1 / 2Cl 2 +H 2 o

[0029] (4) preparation of sodium chlorite: 2ClO 2 +2NaOH+H 2 o 2 →2NaClO 2 +2H 2 O+O 2

[0030] Specifically, the sodium chlorate ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com