Chain or network silica sol and superhydrophilic self-cleaning anti-reflection coating solution and its preparation and application

A silica sol and chain-like technology, applied in the field of anti-reflection coating solutions for glass, can solve the problems of large sol particle size, high refractive index and low refractive index, and achieve obvious power gain, high film hardness and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

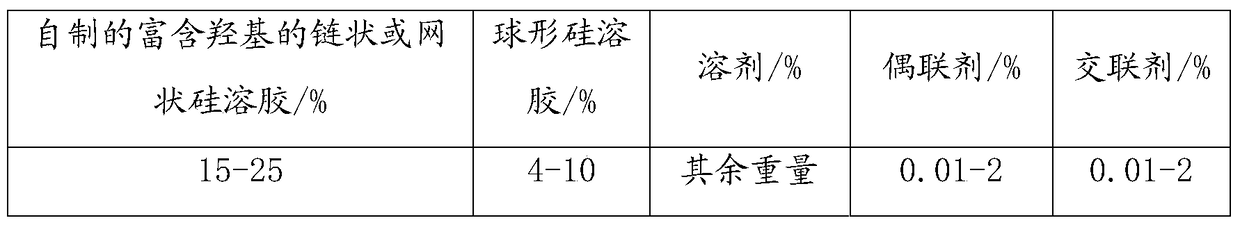

Method used

Image

Examples

Embodiment 1

[0061] (1) Preparation of hydroxyl-rich chain or network silica sol

[0062] (1) Add 100 mL of isopropanol as a solvent into a three-necked flask, and under stirring at 15°C, slowly add deionized water and hydrochloric acid as a catalyst into the three-necked flask, and continue stirring for 30 minutes to obtain liquid A;

[0063] (2) Under the condition of stirring at 15°C, silicone oil (polydimethylsiloxane, commercially available from Shanghai Kaishida Chemical Co., Ltd., model No. PMX-200 silicone oil, 0.65-2cSt) was slowly added to liquid A, and continued to stir for 30 minutes to obtain liquid B;

[0064] (3) Under the condition of stirring at 15°C, mix methyltriethoxysilane and tetraethoxysilane as an alkoxysilane evenly, then slowly add the evenly mixed alkoxysilane into liquid B, and heat up to 40 °C, continue to stir for 0.5h, then stop stirring, age at 25°C for 1 day, and obtain hydroxyl-rich chain or network silica sol after cooling.

[0065] Wherein, the volume...

Embodiment 2

[0093] (1). Preparation of hydroxyl-rich chain or network silica sol

[0094] (1) Add 100 mL of isopropanol as a solvent into the three-necked flask, and under stirring at room temperature, slowly add the uniformly mixed deionized water and oxalic acid as a catalyst into the three-necked flask, and continue stirring for 30 minutes to obtain liquid A;

[0095] (2) Under stirring conditions at room temperature, silicone oil (polydimethylsiloxane, commercially available from Shanghai Kaishida Chemical Co., Ltd., model No. PMX-200 silicone oil, 5-20cSt) was slowly added to liquid A, and continued to stir for 30 minutes to obtain liquid B;

[0096] (3) Under the condition of stirring at room temperature, mix tetramethoxysilane and methyltrimethoxysilane as an alkoxysilane evenly, then slowly add the evenly mixed alkoxysilane into liquid B, and heat up to 80°C Continue to stir for 5 hours, then stop stirring, age at 80°C for 5 days, and obtain hydroxyl-rich chain or network silica...

Embodiment 3

[0118] (1). Preparation of hydroxyl-rich chain or network silica sol

[0119] (1) Add 100 mL of methanol as a solvent into the three-necked flask, and under stirring at 35°C, slowly add the uniformly mixed deionized water and nitric acid as a catalyst into the three-necked flask, and continue stirring for 30 minutes to obtain liquid A;

[0120] (2) Under the condition of stirring at 35°C, silicone oil (polydimethylsiloxane, commercially purchased from Shanghai Kaishida Chemical Co., Ltd., model No. PMX-200 silicone oil, 0.65-2cSt) was slowly added to liquid A, and continued to stir for 30 minutes to obtain liquid B;

[0121] (3) Under the condition of stirring at 35°C, mix tetramethoxysilane, phenyltriethoxysilane and dimethyldiethoxysilane as alkoxysilane evenly, and then mix the evenly mixed alkoxysilane Slowly add silane into liquid B, raise the temperature to 50°C and continue to stir for 3 hours, then stop stirring, age at 70°C for 5 days, and obtain hydroxyl-rich chain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com