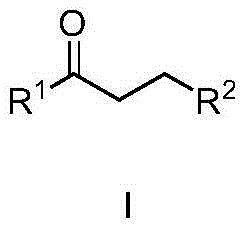

Method for synthesizing alpha-alkyl ketone

A technology of alkyl ketone and alkyl group, which is applied in the field of synthesis of α-alkyl ketone and achieves the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

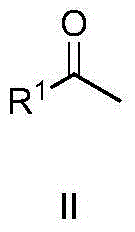

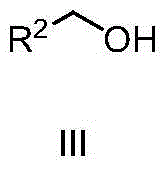

[0025] Example 1: 1,3-diphenyl-1-propanone

[0026] 1,3-diphenylpropan-1-one

[0027]

[0028] Acetophenone (120mg, 1mmol), cat.1 (5.4mg, 0.01mmol, 1mol%), cesium carbonate (33mg, 0.1mmol, 0.1equiv.), benzyl alcohol (120mg, 1.1mmol) and tert-amyl alcohol ( 1ml) into a 5mL round bottom flask in turn. The reaction mixture was refluxed in air for 6 hours and then cooled to room temperature. Rotary evaporation removes solvent, then obtains pure target compound by column chromatography (developing solvent: sherwood oil / ethyl acetate), productive rate: 92%

[0029] 1 HNMR (500MHz, CDCl 3 )δ7.96(d, J=7.2Hz, 2H, ArH), 7.55(t, J=6.9Hz, 1H, ArH), 7.45(t, J=6.9Hz, 2H, ArH), 7.34-7.23(m ,4H,ArH),7.20(t,J=6.7Hz,1H,ArH),3.30(t,J=7.3Hz,2H,CH 2 ), 3.07(t, J=7.3Hz, 2H, CH 2 ); 13 CNMR (125MHz, CDCl 3 )δ 199.2, 141.3, 136.9, 133.0, 128.6, 128.5, 128.4, 128.0, 126.1, 40.4, 30.1.

Embodiment 2

[0030] Example 2: 3-(4-methylphenyl)-1-phenyl-1-propanone

[0031] 1-phenyl-3-p-tolylpropan-1-one

[0032]

[0033] Acetophenone (120mg, 1mmol), cat.1 (5.4mg, 0.01mmol, 1mol%), cesium carbonate (33mg, 0.1mmol, 0.1equiv.), 4-methylbenzyl alcohol (135mg, 1.1mmol) and Tert-amyl alcohol (1 mL) was sequentially added to a 5 mL round bottom flask. The reaction mixture was refluxed in air for 6 hours and then cooled to room temperature. Rotary evaporation removes solvent, then obtains pure target compound by column chromatography (developing solvent: sherwood oil / ethyl acetate), productive rate: 88%

[0034] 1 HNMR (500MHz, CDCl 3 )δ7.96(d, J=6.4Hz, 2H, ArH), 7.55(t, J=7.1Hz, 1H, ArH), 7.45(t, J=7.4Hz, 2H, ArH), 7.21-7.05(m ,4H,ArH),3.28(t,J=7.2Hz,2H,CH 2 ), 3.03(t, J=7.2Hz, 2H, CH 2 ),2.32(s,3H,CH 3 ); 13 CNMR (125MHz, CDCl 3 )δ 199.3, 138.2, 136.9, 135.6, 133.0, 129.2, 128.6, 128.3, 128.0, 40.6, 29.7, 21.0.

Embodiment 3

[0035] Example 3: 3-(4-methoxyphenyl)-1-phenyl-1-propanone

[0036]3-(4-methoxyphenyl)-1-phenylpropan-1-one

[0037]

[0038] Acetophenone (120mg, 1mmol), cat.1 (5.4mg, 0.01mmol, 1.0mol%), cesium carbonate (33mg, 0.1mmol, 0.1equiv.), 4-methoxybenzyl alcohol (152mg, 1.1mmol ) and tert-amyl alcohol (1 mL) were sequentially added to a 5 mL round bottom flask. The reaction mixture was refluxed in air for 6 hours and then cooled to room temperature. Rotary evaporation removes solvent, then obtains pure target compound by column chromatography (developing solvent: sherwood oil / ethyl acetate), productive rate: 90%

[0039] 1 HNMR (500MHz, CDCl 3 )δ7.96(d, J=7.5Hz, 2H, ArH), 7.55(t, J=7.1Hz, 1H, ArH), 7.45(t, J=7.4Hz, 2H, ArH), 7.17(d, J =8.0Hz,2H,ArH),6.84(d,J=8.0Hz,2H,ArH),3.79(s,3H,CH 3 )3.27(t, J=7.5Hz, 2H, CH 2 ), 3.01(t, J=7.5Hz, 2H, CH 2 ); 13 CNMR (125MHz, CDCl 3 )δ199.3, 157.9, 136.8, 133.3, 133.0, 129.3, 128.5, 128.0, 113.9, 55.2, 40.7, 29.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com