An anticorrosion wear-resistant coating for an aluminium alloy surface and a preparing method thereof

An aluminum alloy surface, anti-corrosion and wear-resistant technology, applied in the direction of anti-corrosion coating, metal material coating process, coating, etc., can solve the problems of poor film stability and unsatisfactory use effect, and achieve excellent friction resistance and anti-corrosion performance Excellent and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In a typical embodiment, the preparation method of the aluminum alloy surface anticorrosion wear-resistant coating of the present invention can comprise:

[0030] Texturing the surface of the aluminum alloy substrate to form a textured layer mainly composed of micro-nano structures;

[0031] The surface of the aluminum alloy substrate is immersed in a solution containing hydrolysis products of more than one organosilicon compound, so as to self-assemble on the textured layer to form a monomolecular silane film.

[0032] Wherein, the "micro-nano structure" is a micro / nano-scale composite undulating morphology formed by a combination of micro / nano-scale protrusions and / or depressions distributed on the surface of the aluminum alloy substrate.

[0033] Preferably, the aluminum alloy substrate having the monomolecular silane film on the surface can also be heat treated.

[0034] As one of the preferred implementation manners, the aluminum alloy substrate can be treated by ...

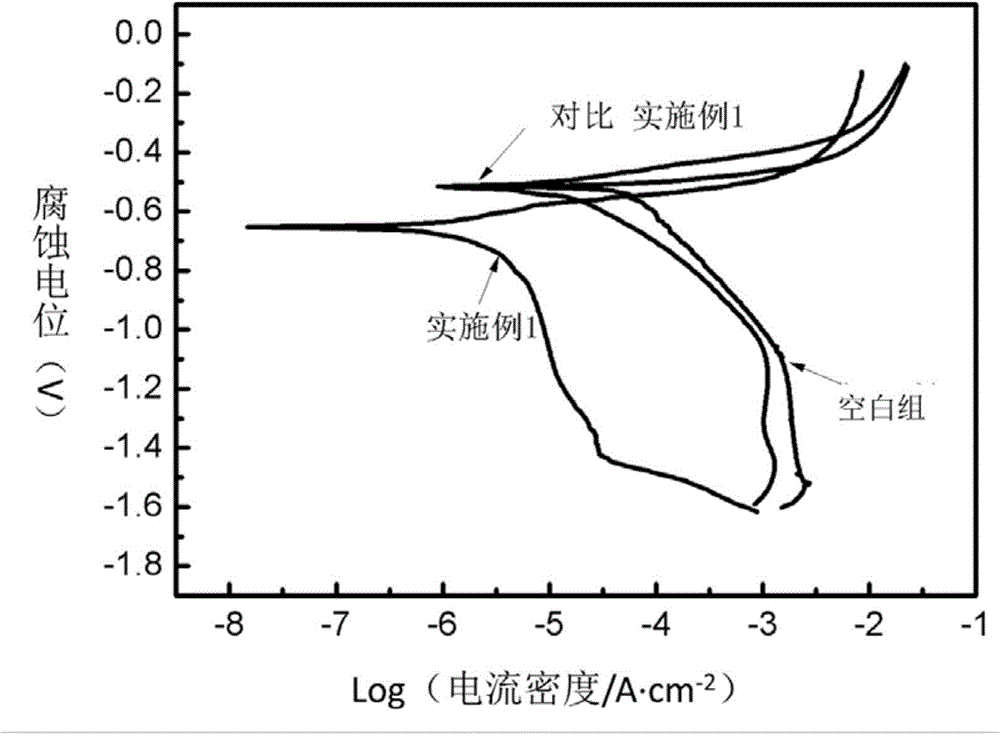

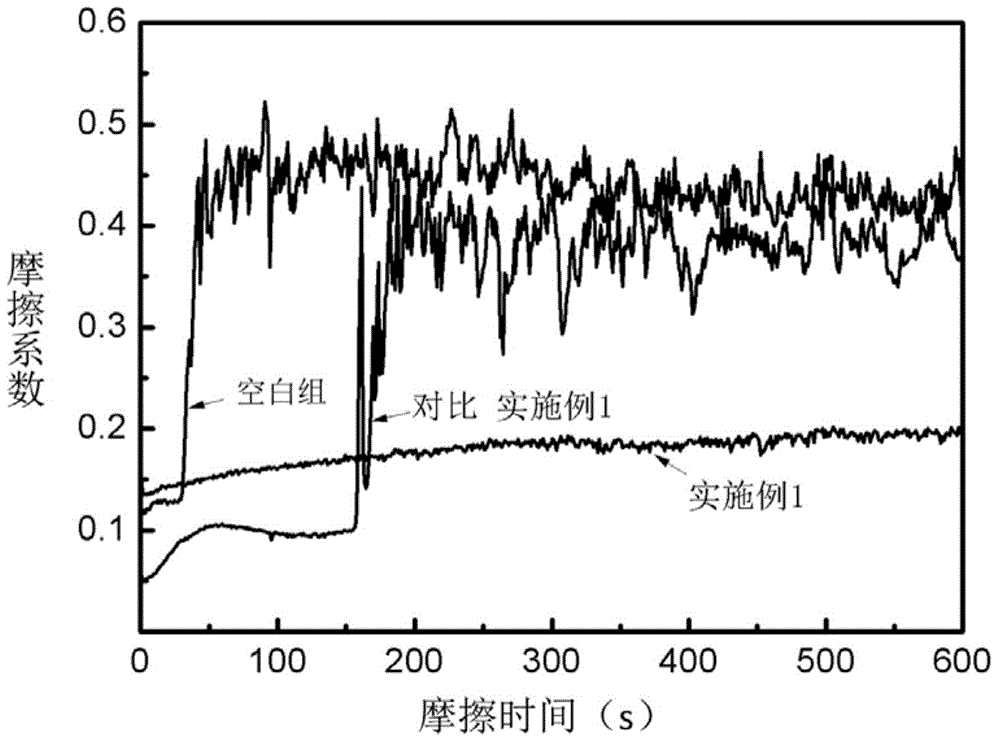

Embodiment 1

[0046] Wash the aluminum alloy with acetone and deionized water for 10 minutes respectively; then soak it in 40% hydrochloric acid aqueous solution for texturing treatment, the soaking temperature is room temperature, and the soaking time is 30s. Figure 7a The textured surface with micro-nano structure is shown; then the aluminum alloy sheet is put into the hydrolyzed octadecyltriethoxysilane solution, the immersion temperature is room temperature, and the immersion time is 12h, followed by heat treatment, heat treatment The temperature is 80° C. to obtain an anti-corrosion and wear-resistant coating on the surface of the aluminum alloy.

[0047] Comparative Example 1 (Comparative Example 1):

[0048] This comparative example is a comparative example of Example 1.

[0049] In this comparative example, no texturing treatment was performed on the aluminum alloy substrate, only the surface was self-assembled with silane solution, the assembly temperature was room temperature, a...

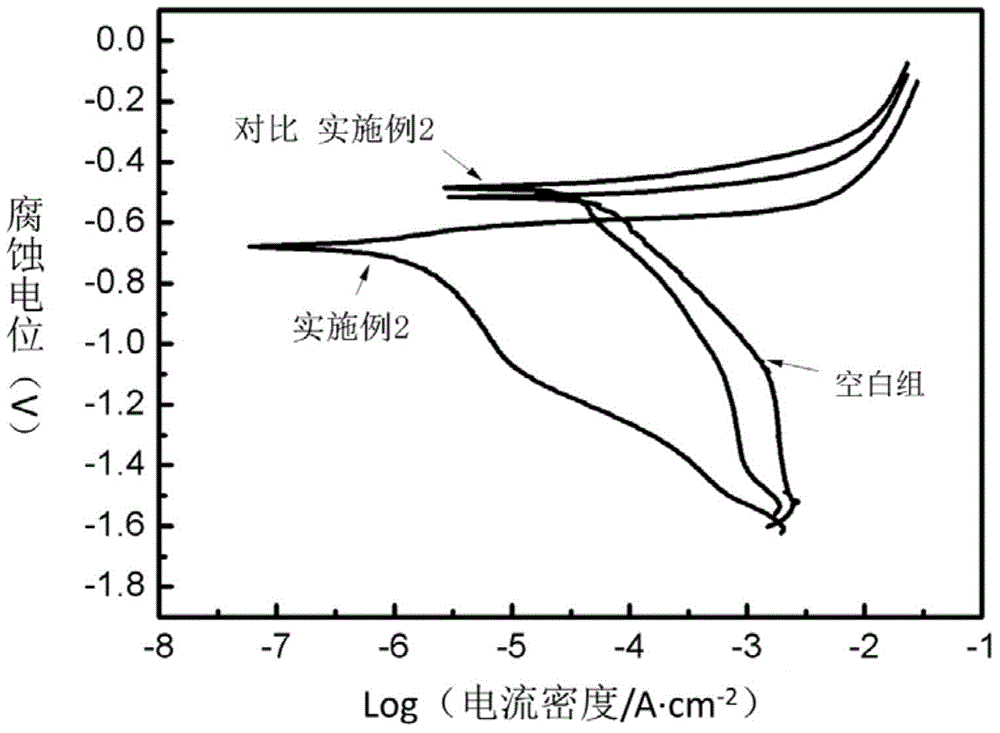

Embodiment 2

[0059] Wash the aluminum alloy with acetone and deionized water for 10 minutes respectively; Figure 7b The immersion temperature of the textured surface with micro-nano structure shown is room temperature, and the immersion time is 120s; then the aluminum alloy sheet is put into the hydrolyzed dodecyltriethoxysilane solution, the immersion temperature is room temperature, and the immersion time is 120s. The time is 12 hours, and then heat treatment is performed, and the heat treatment temperature is 80° C. to obtain an anti-corrosion and wear-resistant coating on the surface of the aluminum alloy.

[0060] Comparative example 2 (comparative example 2):

[0061] This comparative example is a comparative example of Example 2.

[0062] In this comparative example, no texturing treatment was performed on the aluminum alloy substrate, only the surface was self-assembled with silane solution, the assembly temperature was room temperature, and the assembly time was 12 hours, foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com