Ultra-high molecular weight polyethylene fiber and preparation method thereof

An ultra-high molecular weight, polyethylene fiber technology, applied in the chemical post-treatment of synthetic polymer rayon filaments, textiles and papermaking, etc., can solve the problems of affecting the mechanical properties of fibers, poor spinnability of polyethylene fibers, etc. Convenience, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

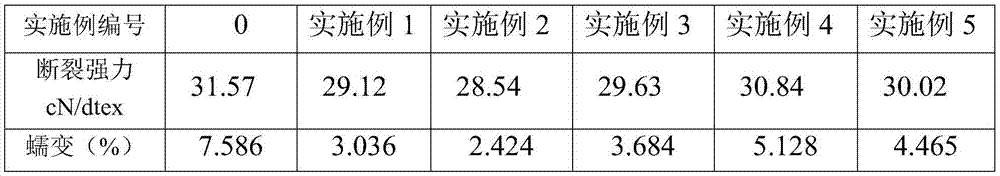

Examples

Embodiment 1

[0023] With acetone as a solvent, triallyl cyanurate is dissolved in acetone to prepare an acetone solution with a mass concentration of triallyl cyanurate of 2%. The ultra-high molecular weight polyethylene as-spun fibers after solvent extraction were placed in the acetone solution and immersed for 20 minutes, and the mass ratio of the acetone solution to the ultra-high-molecular-weight polyethylene as-spun fibers was 5:1.

[0024] The as-spun silk was taken out from the acetone solution, dried naturally in the air, and then subjected to four-stage thermal drawing in hot air at 70°C, 100°C, 120°C and 140°C, with a total draw ratio of 15 times.

[0025] Under the protection of nitrogen, the drawn fibers were irradiated by an electron beam device with a dose rate of 5 kGy / s, and the irradiation dose was 10 kGy, to obtain irradiated cross-linked ultra-high molecular weight polyethylene fibers.

Embodiment 2

[0027] With tetrahydrofuran as a solvent, triallyl isocyanurate is dissolved in tetrahydrofuran to prepare a tetrahydrofuran solution with a mass concentration of triallyl isocyanurate of 4%. The ultra-high molecular weight polyethylene as-spun fibers after solvent extraction were placed in the tetrahydrofuran solution and immersed for 30 minutes. The mass ratio of the tetrahydrofuran solution to the ultra-high-molecular-weight polyethylene as-spun fibers was 10:1.

[0028] The as-spun silk was taken out from the tetrahydrofuran solution, dried naturally in the air, and then subjected to four-stage thermal drawing in hot air at 90°C, 110°C and 140°C, with a total draw ratio of 20 times.

[0029] Under the protection of acetylene, the stretched fibers were irradiated by an electron beam device with a dose rate of 5 kGy / s, and the radiation dose was 20 kGy, to obtain irradiated cross-linked ultra-high molecular weight polyethylene fibers.

Embodiment 3

[0031] Using ethanol as a solvent, 1,6-hexanediol diacrylate was dissolved in ethanol to prepare an ethanol solution with a mass concentration of 1,6-hexanediol diacrylate of 6%. The ultra-high molecular weight polyethylene as-spun fibers after solvent extraction were placed in the ethanol solution, and immersed for 30 minutes, and the mass ratio of the ethanol solution to the ultra-high-molecular-weight polyethylene as-spun fibers was 20:1.

[0032] The as-spun silk was taken out from the ethanol solution, dried naturally in the air, and then subjected to five-stage thermal drawing in hot air at 90°C, 110°C, 120°C, 130°C and 140°C, with a total draw ratio of 24 times.

[0033] The drawn fiber was irradiated by an electron beam device with a dose rate of 10kGy / s under vacuum, and the irradiation dose was 40kGy, to obtain an ultra-high molecular weight polyethylene fiber crosslinked by irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com