300mwcfb boiler for burning oil shale and its layout method

An oil shale and boiler technology, which is applied in the field of 300MWCFB boilers, can solve the problems of difficult design of large-capacity boilers, great influence of combustion in the furnace, and strong abrasion of oil shale, so as to reduce the amount of ignition oil and prolong the residence time. , mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

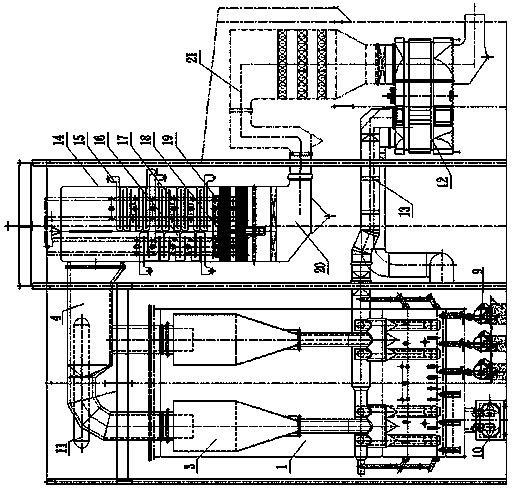

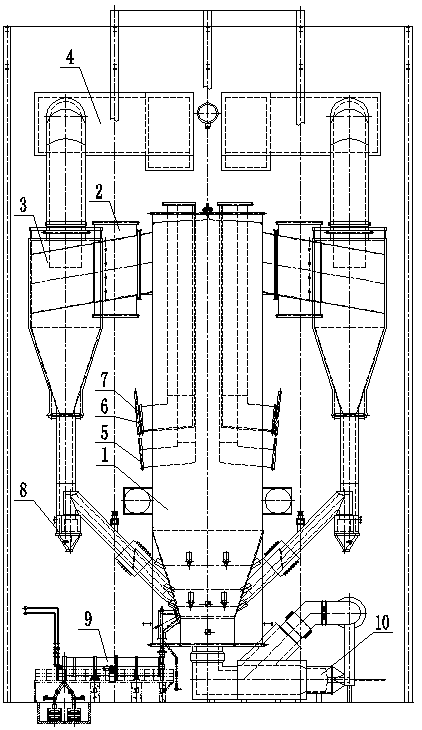

[0020] A 300MW CFB boiler for burning oil shale, which consists of: a boiler body, the front of the boiler body is provided with a square furnace 1, and a pot is arranged directly above the square furnace and in the center of the furnace. A cylinder 11, a slag cooler 9 and an under-bed start-up burner 10 are provided below the square furnace, and a water cooling screen 5, a high-temperature reheater 6 and a high-temperature superheater 7 are arranged in the central area of the upper space in the square furnace, Both sides of the square furnace are symmetrically arranged with steam-water separators 3, the upper part of the steam-water separator is connected to the square furnace through the inlet flue 2, and the lower part of the steam-water separator is connected to the square furnace through the return valve 8, The steam-water separator communicates with the tail wall superheater 14 through the outlet flue 4 .

Embodiment 2

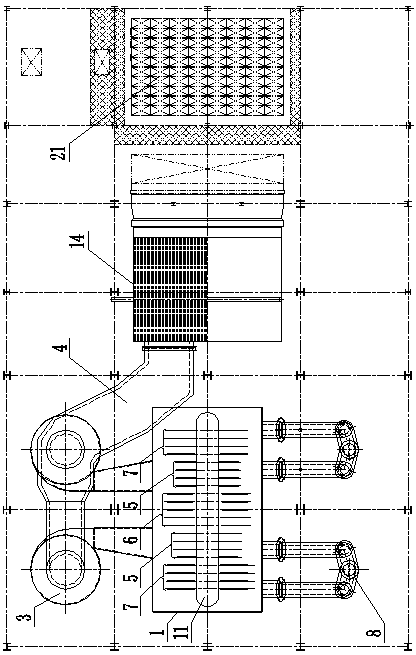

[0022] According to the 300MW CFB boiler for burning oil shale described in Embodiment 1, the described wall-enclosed superheater is arranged directly behind the square furnace, and the described wall-enclosed superheater is divided into front and rear two flues, and the described A low-temperature reheater and an economizer A18 are arranged sequentially from top to bottom in the front flue of the wall superheater, and a medium-temperature superheater 15, a low-temperature superheater 16, and an economizer are arranged in sequence from top to bottom in the rear flue of the wall superheater. Coal boiler B19, the economizer ash hopper 20 is located below the wall-enclosed superheater, the SCR device 21 is connected behind the economizer ash hopper, and an air preheater 12 is installed under the SCR device. The air preheater is connected to the square furnace through the hot air duct, and the flue gas outlet and air inlet of the air preheater are respectively connected to the flue...

Embodiment 3

[0024] According to the 300MW CFB boiler for burning oil shale described in Embodiment 1 or 2, the centerline of the square furnace coincides with the centerline of the boiler body, the slag cooler is drawn from the left side of the square furnace, and the The starter under the bed is led out from the right side of the square furnace, the wall-enclosed superheater is square, and the centerline of the wall-enclosed superheater coincides with the centerline of the boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com