Material structure used for realizing InGaAs light absorption wavelength expansion

A material structure, light absorption technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large dark current of InAs, slow response speed of PbSe, low light detection rate, etc., to achieve high microstrip density of states and practical value. The effect of high and large light absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

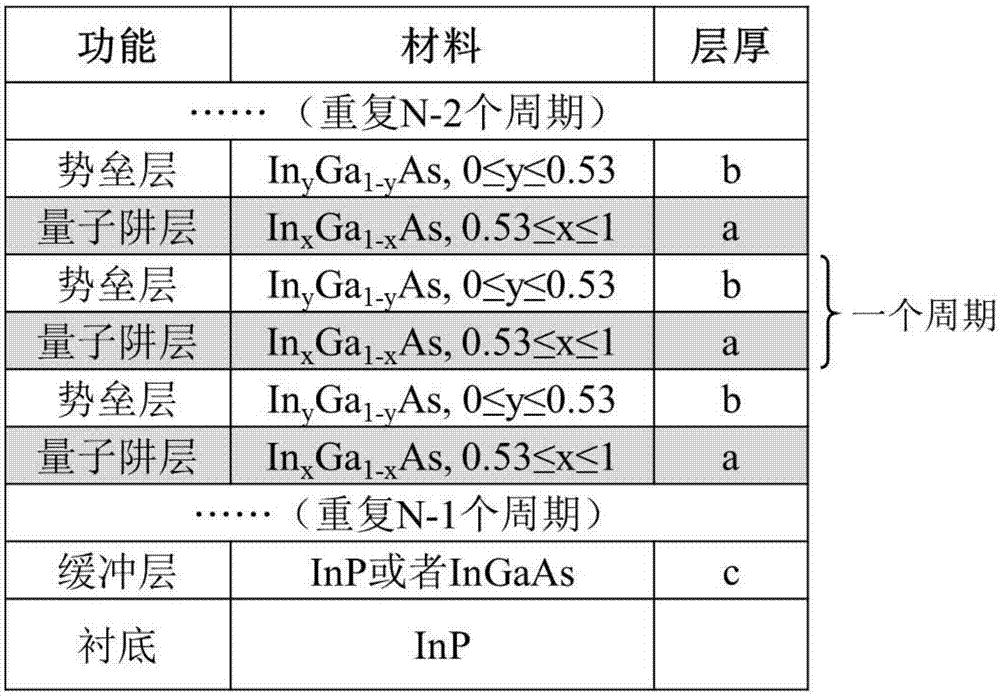

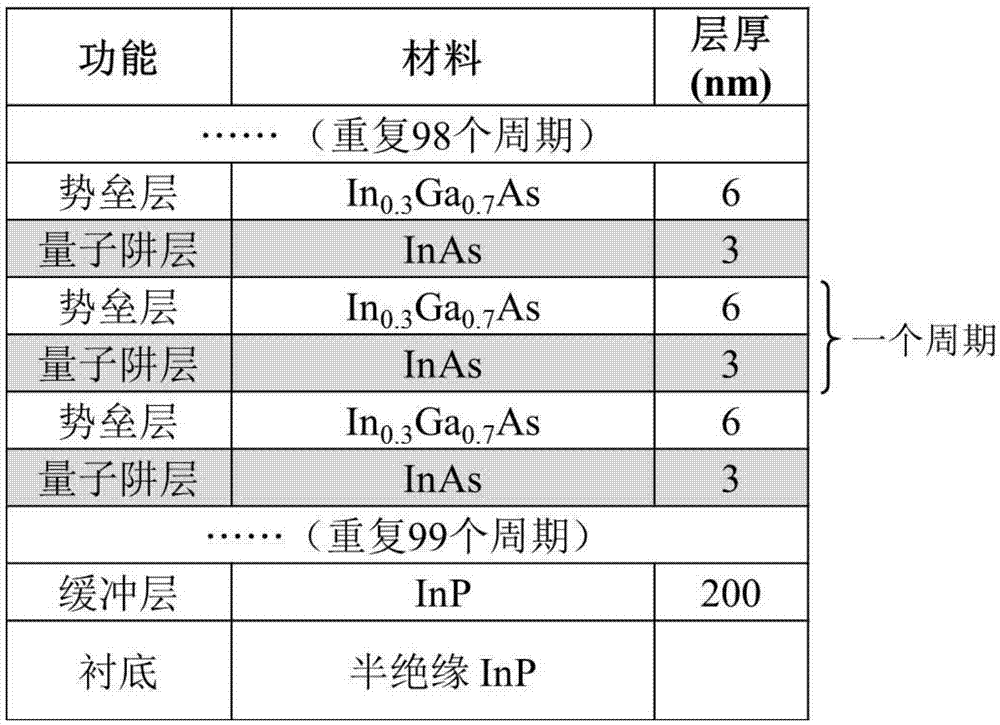

[0038] Growth of InGaAs strain-compensated quantum well superlattice structure with light absorption long-wavelength cut-off wavelength of 2.1 μm:

[0039] The purpose of this embodiment is to obtain an InGaAs strain-compensated quantum well superlattice material structure with a light absorption long-wave cut-off wavelength of 2.1 μm. The quantum wells and barrier layers shown in this embodiment are all made of InGaAs single-layer material with a fixed In composition, and neither includes a sub-layer structure. Each superlattice period contains a layer of 3nm thick InAs compressive strain quantum well, a layer of 6nm thick In 0.3 Ga 0.7 As tensile strain barrier. The overall strain compensation of the material is close to 100%. Specific material structures such as figure 2 shown. Its structure contains the following materials in order from bottom to top:

[0040] Material 1: semi-insulating InP (001) substrate.

[0041] Material 2: non-doped InP buffer layer with a th...

Embodiment 2

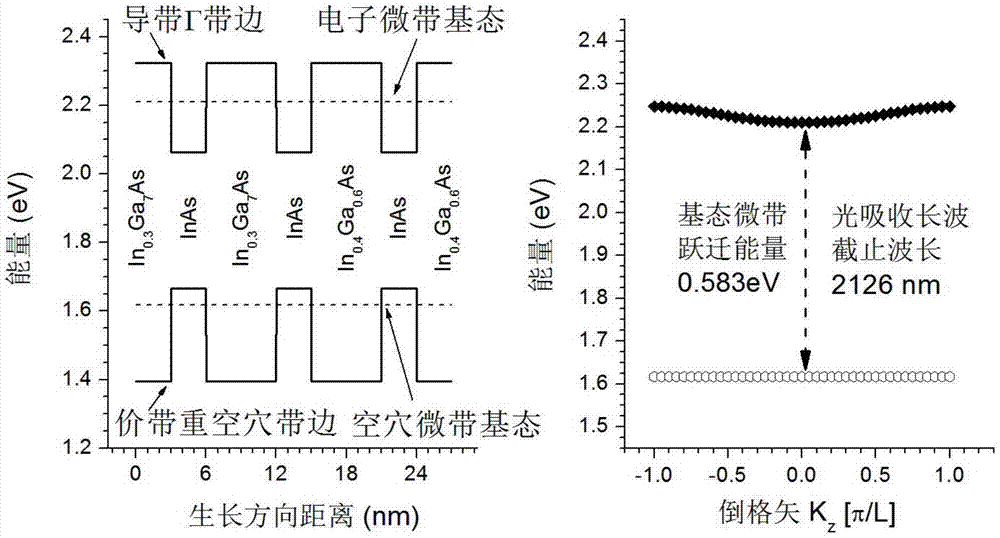

[0050] Growth of InGaAs strain-compensated quantum well superlattice structure with light absorption long-wave cut-off wavelength of 2.5 μm:

[0051] The purpose of this embodiment is to obtain an InGaAs strain-compensated quantum well superlattice material structure with a light absorption long-wave cut-off wavelength of 2.5 μm. The quantum well shown in this embodiment adopts InGaAs single-layer material with fixed In composition and does not include sub-layer structure. The barrier layer adopts an asymmetric barrier structure, including two InGaAs sublayer structures with different In compositions. Each superlattice period contains three layers of material: the compressive strain quantum well is a layer of InAs with a thickness of 1.53nm, and one side of the quantum well is a layer of InAs with a thickness of 2nm. 0.3 Ga 0.7 As tensile strain barrier, the other side is a layer of 2nm thick In 0.4 Ga 0.6 As tensile strain barrier. The overall strain compensation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com