Electrode preparation method for improving current expansion and luminous efficiency of GaAs-based light-emitting diode

A light-emitting diode and current expansion technology, which is applied in the field of optoelectronics, can solve the problems of low light extraction efficiency and poor current expansion effect, and achieve the effects of improving current expansion efficiency, improving light extraction efficiency, and avoiding absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

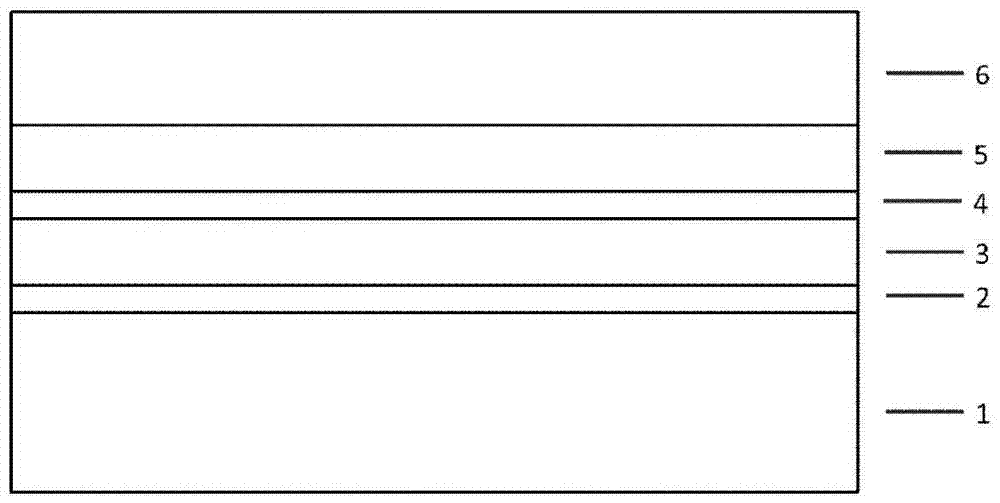

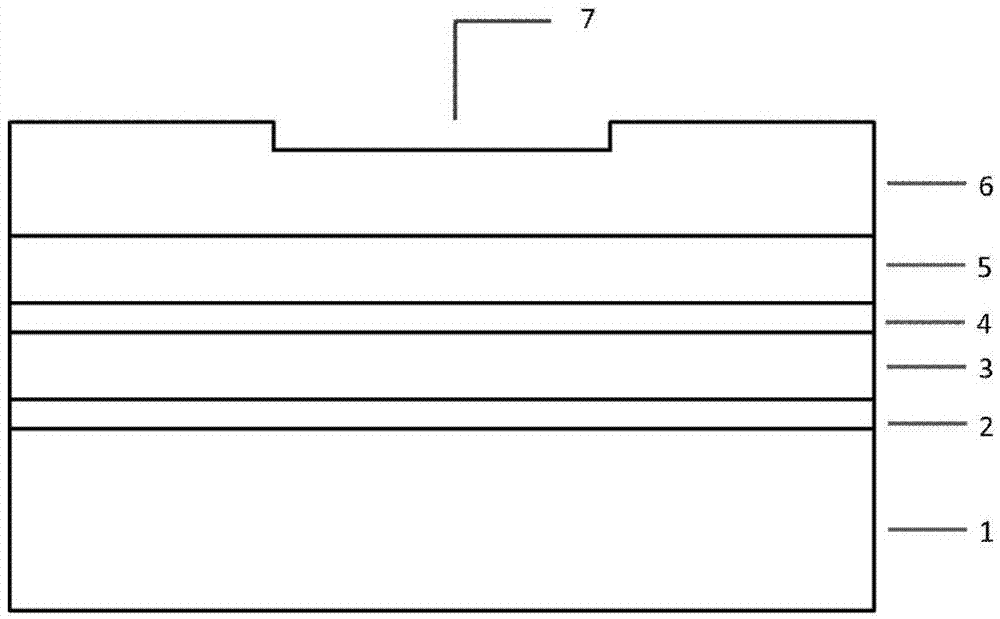

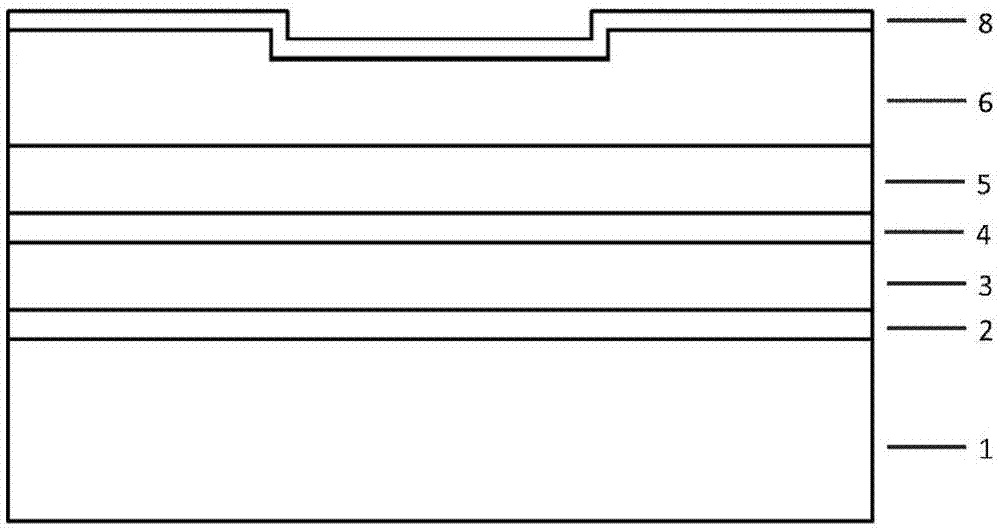

[0038] An electrode preparation method for improving the current expansion and light extraction efficiency of GaAs-based light-emitting diodes, comprising the following steps:

[0039](1) Current blocking area: Utilize photoresist coating and plasma etching to prepare pattern recessed area on GaAs base epitaxial wafer, and remove photoresist; Described step (1) utilizes photoresist coating to refer to GaAs base epitaxial wafer Coat photoresist on the epitaxial wafer, and photolithographically pattern; use a glue spinner to evenly coat a layer of photoresist on the GaAs-based epitaxial wafer, the photoresist is positive photoresist, and the thickness of the photoresist is 1.2-1.5 μm; Use an exposure machine to expose, then develop and harden the film to produce the required photolithographic pattern; use plasma etching to etch the p-type current spreading layer 6 in the photolithographic pattern area to form a current blocking region 7, such as figure 2 As shown, the etching d...

Embodiment 2

[0046] As described in Example 1, the electrode preparation method for improving the current expansion and light extraction efficiency of GaAs-based light-emitting diodes, the difference is that in the step (2), the ITO film is deposited on the GaAs-based epitaxial wafer by magnetron sputtering method completed.

[0047] The method for evaporating a metal thin film on the surface of the GaAs substrate in the step (6) is an electron beam evaporation method.

Embodiment 3

[0049] A kind of electrode preparation method that improves GaAs-based light-emitting diode current expansion and light extraction efficiency as described in embodiment 1, and its difference is that, the lithography pattern described in described step (1) and step (3) is circular; The diameter of the photolithographic pattern in the step (1) is 10±5 μm longer than the diameter of the photolithographic pattern in the step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com