Preparation method of chewable tablets containing chitosan oligosaccharide

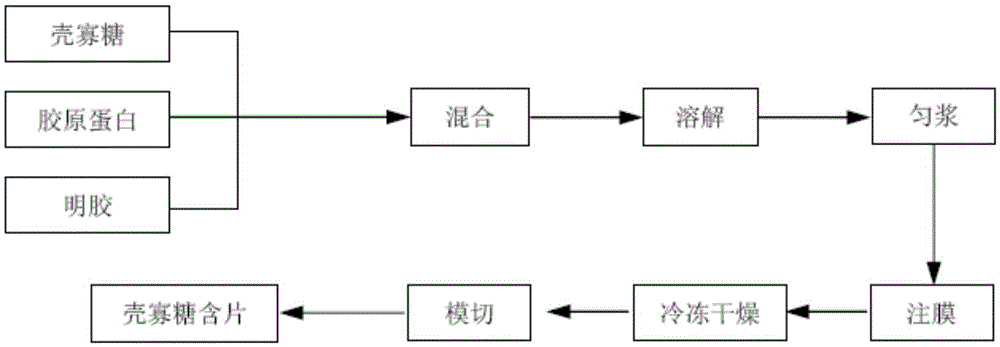

A technology of chitosan oligosaccharides and chewable tablets, which is applied in the field of food science, can solve the problems of inconvenient application, small amount of chitosan oligosaccharides, and unsatisfactory taste, etc., and achieves the effects of portability, low water content, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 0.3 kg of chitosan (polymer 12), 2 kg of collagen (average molecular weight 3200 Da) and 7.7 kg of gelatin (average molecular weight 25000 Da), and mix them uniformly.

[0022] (2) Add the chitosan oligosaccharide, collagen and gelatin mixture obtained in step (1) into 400kg of pure water, stir at 70°C for 15min, and press filter twice through a 300-mesh screen to make it fully mixed to form homogenate.

[0023] (3) Pour chitosan oligosaccharide, collagen and gelatin homogenate obtained in step (2) into a mould, the depth of the homogenate layer is controlled at 10mm, and the surface is scraped off with a spatula.

[0024] (4) Put the mold containing chitosan oligosaccharide, collagen and gelatin homogenate in step (3) into a freeze dryer, pre-freeze at -40°C for 60 minutes, then vacuumize and freeze-dry for 16 hours, and the film after freeze-drying The water content is controlled at 4.8%.

[0025] (5) Die-cut the oligochitosan, collagen and gelatin film pr...

Embodiment 2

[0027] (1) Weigh 0.2kg of chitosan (polymer 14), 3kg of collagen (average molecular weight 3600Da) and 6.8kg of gelatin (average molecular weight 30000Da), and mix them uniformly.

[0028] (2) Add the chitosan oligosaccharide, collagen and gelatin mixture obtained in step (1) into 300kg of pure water, stir at 65°C for 20min, and press filter twice through a 250-mesh screen, so that it is fully mixed to form homogenate.

[0029] (3) Pour chitosan oligosaccharide, collagen and gelatin homogenate obtained in step (2) into a mould, the depth of the homogenate layer is controlled at 15mm, and the surface is scraped off with a spatula.

[0030] (4) Put the mold filled with chitosan oligosaccharide, collagen and gelatin homogenate in step (3) into a freeze dryer, pre-freeze at -40°C for 40 minutes, then vacuumize and freeze-dry for 20 hours, and the freeze-dried film The water content is controlled at 3.6%.

[0031] (5) Die-cut the oligochitosan, collagen and gelatin film prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com