Hydrogel composition for masking pack containing water-soluble polyurethane

A technology of water-soluble polyurethane and composition, applied in the direction of medical preparations containing active ingredients, dressing preparations, skin care preparations, etc., can solve the problems of environmental protection, skin softening, low air permeability, etc., and improve production Efficiency, increased production efficiency, and improved tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~2

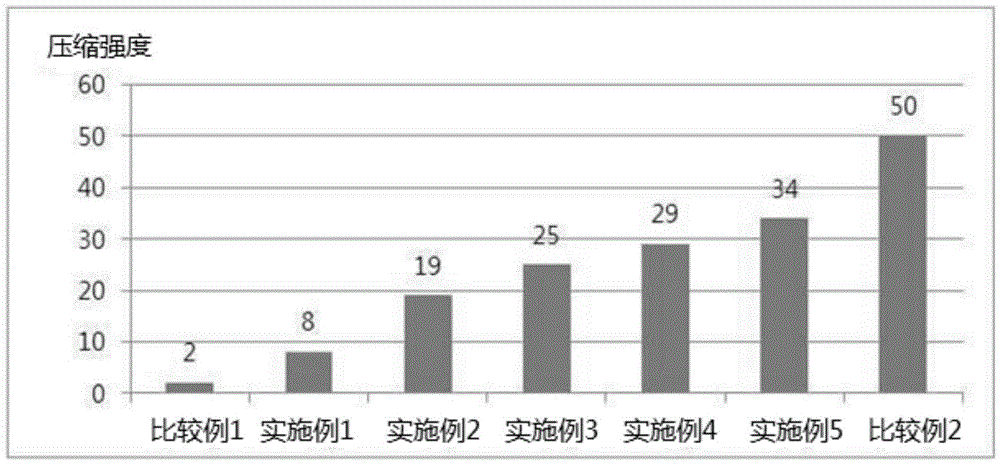

[0053] In order to determine the mixing ratio of the natural polymer gelling agent carrageenan and other natural polymer gelling agents, the following Examples and Comparative Examples were carried out.

[0054] In Examples 1 to 5 and Comparative Examples 1 to 2, the mixing ratio of carrageenan and cinnamon gum was adjusted in the range of 0.2 to 0.8% by weight, and stirred at 75° C. for 30 minutes to produce a hydrogel composition.

[0055] 【Table 1】

[0056]

[0057] The compressive strength was measured and confirmed for the state of the hydrogel composition of the composition.

[0058] The gel strength was measured at normal temperature using Instron5569 (Instronco. USA). The thickness of the test piece used for measurement is 5.0 mm, and its diameter is 10 mm. Three test pieces are manufactured for each sample and measured. During the measurement, the crosshead speed was 10 mm / min., and the compressive strength of the test piece was measured when 50% of the deformati...

Embodiment 6~10 and comparative example 3~4

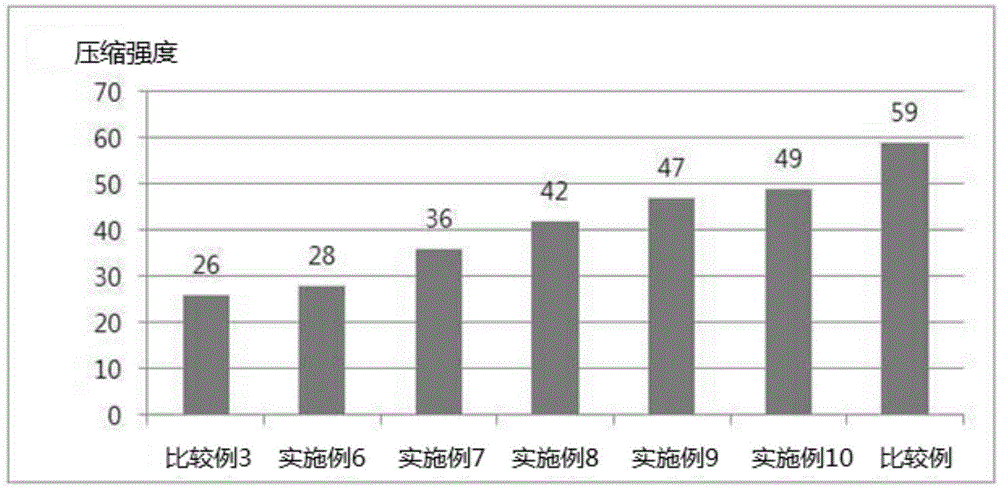

[0061] In order to determine the preferable electrolyte content, experiments of the following examples and comparative examples were carried out.

[0062] In Examples 6 to 10 and Comparative Examples 3 to 4, cinnamon gum and carrageenan were respectively maintained at 0.5% by weight, potassium chloride was changed to 0.09 to 1.1% by weight, and stirred at 75°C for 30 minutes to produce water Gel composition.

[0063] 【Table 2】

[0064]

[0065] The compressive strength was measured and confirmed for the state of the hydrogel composition of the composition.

[0066] The gel strength was measured at normal temperature using Instron5569 (Instronco. USA). The thickness of the test piece used for measurement is 5.0 mm, and its diameter is 10 mm. Three test pieces are manufactured for each sample and measured. During the measurement, the crosshead speed was 10 mm / min., and the compressive strength of the test piece was measured when 50% of the deformation was achieved.

[006...

Embodiment 11~14 and comparative example 5~6

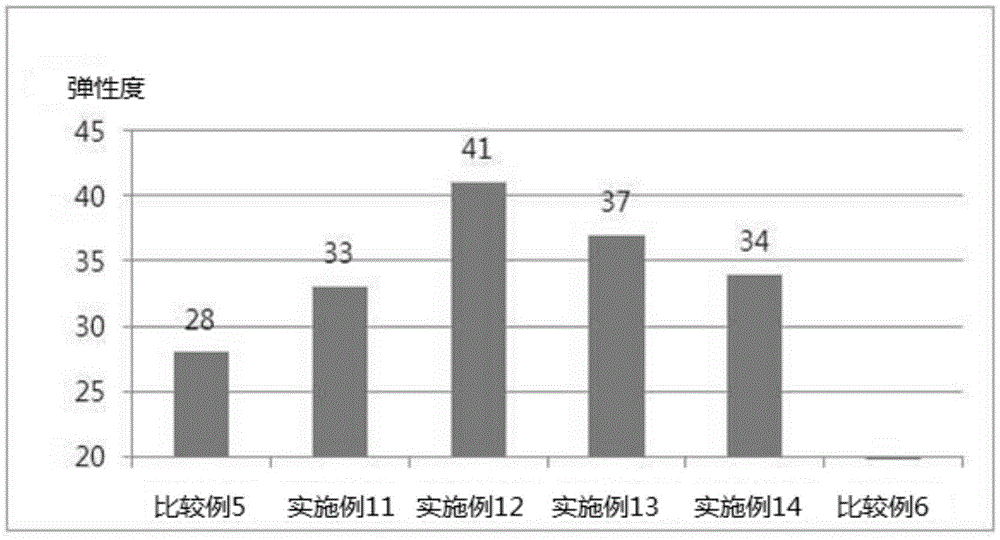

[0069] In order to confirm the preferable content ratio of water-soluble polyurethane, the experiment of the following Example and a comparative example was performed.

[0070] In Examples 11-14 and Comparative Examples 5-6, 0.5% by weight of cinnamon gum, 0.5% by weight of carrageenan, and 0.2% by weight of potassium chloride were maintained in the purified water, and the water-soluble polyurethane was adjusted within the range of 0.009-5.5% by weight. , and stirred at 75° C. for 30 minutes to prepare a hydrogel composition.

[0071] 【table 3】

[0072]

[0073] The gel elastic properties of the fabricated hydrogel compositions were confirmed.

[0074] Gel elasticity was measured at normal temperature using Instron5569 (Instronco. USA). The thickness of the test piece used for measurement is 5.0 mm, and its diameter is 10 mm. Three test pieces are manufactured for each sample and measured. During the measurement, the speed of the crosshead (Crosshead) was 10mm / min., and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com