Preparation method for drug-carrier mode composite micro-powder

A drug and carrier technology, applied in the field of drug-carrier mode compound micropowder preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

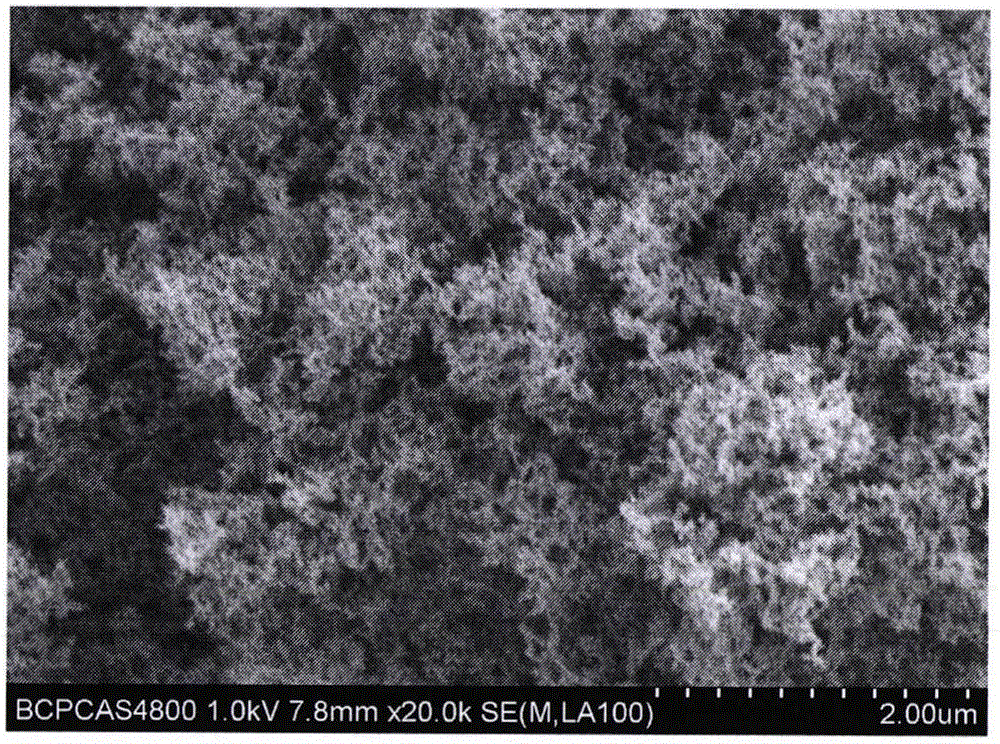

[0038] figure 1 It is the scanning electron microscope microscopic morphology of fumed silica. The geometric particle size of individual fumed silica particles is 5-20nm, and the geometric particle size of aggregates is 1-10μm. Fumed silica is divided into two types: hydrophobic and hydrophilic, and the corresponding type is selected according to the properties of the dispersion medium in the preparation of the composite micropowder.

Embodiment 2

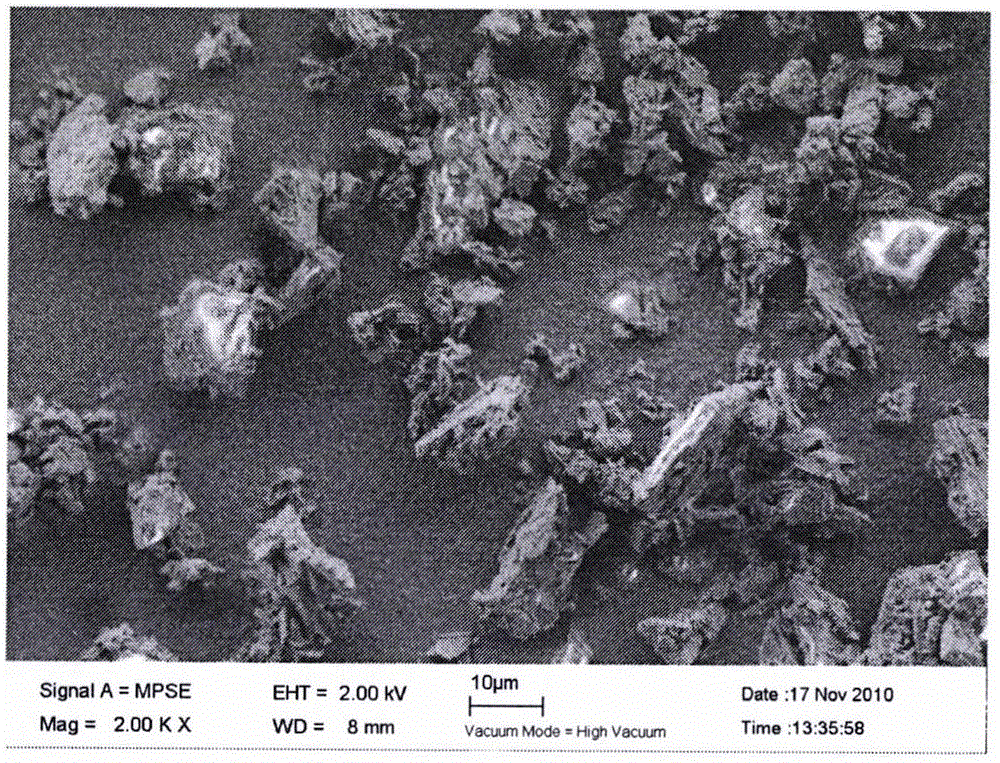

[0040] Pentoxyverine citrate is a widely used non-addictive antitussive. In addition to its direct inhibitory effect on the respiratory center, it also has a weak atropine effect, which can slightly inhibit the endobronchial receptors and weaken the cough reflex. It can relax the spastic bronchial smooth muscle, reduce airway resistance, and is suitable for inhalation and local drug administration in the respiratory tract. The raw material of pentoxyverine citrate has a purity higher than 99%. It is fully dried and ground after recrystallization. Its macroscopic appearance is white powder. Scanning electron microscope microscopic appearance as figure 2 shown.

Embodiment 3

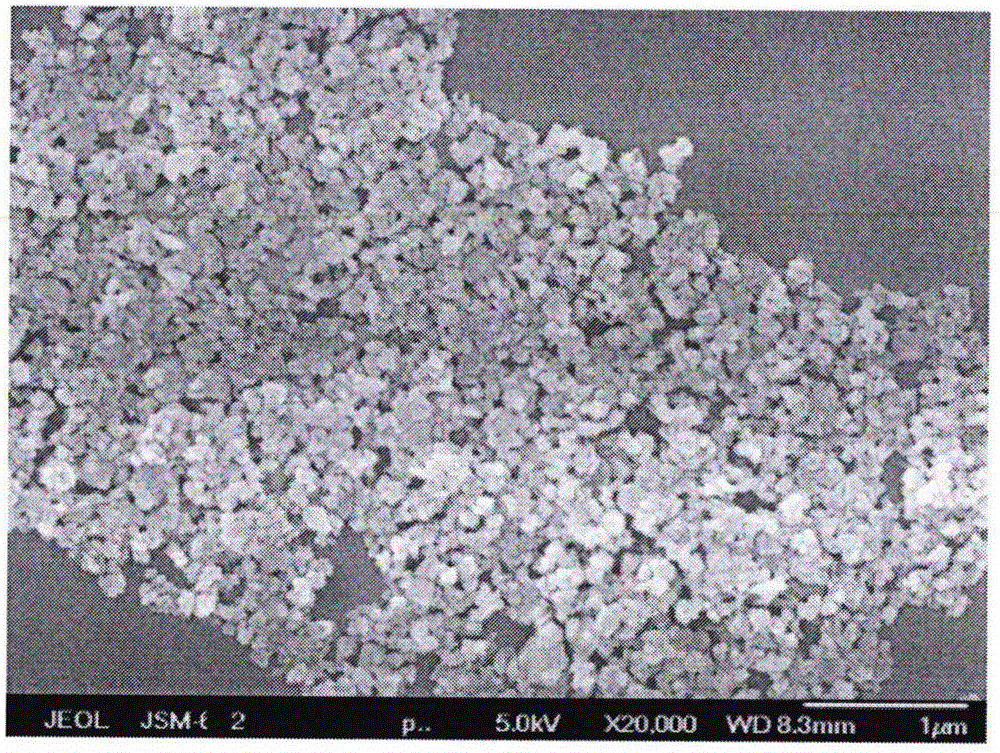

[0042] Pentoxyverine citrate suspended particles with a geometric particle size of 10-1000nm were prepared by high-pressure homogenization: disperse pentoxyverine citrate in isopropanol, and the concentration of pentoxyverine citrate was 1.5 twice the concentration of the saturated solution.

[0043] With 750Bar as the homogenization pressure, adjust the number of homogenization: when the number of homogenization is 1-2 times, the homogenization process is not smooth, there is clogging, and the geometric particle size of the suspended particles is greater than 1 μm; when the number of homogenization is 3-4 times, The homogenization process is smooth without clogging, and the geometric particle size of the suspended particles is 400-800nm; when the number of homogenization is 5 times, the geometric particle size of the suspended particles is 100-200nm; continue to increase the number of homogenizations, and choose 10 times of homogenization , 15 times, 20 times, 30 times, the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com