Preparation method of FexOy/SiO2 aerogel nano-composite

A nanocomposite material and airgel technology, which is applied in the field of preparation of FexOy/SiO2 airgel nanocomposite materials, can solve the problems of long processing time, high sintering temperature, high risk, etc., and achieve the change of harsh conditions and preparation process Controllable, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

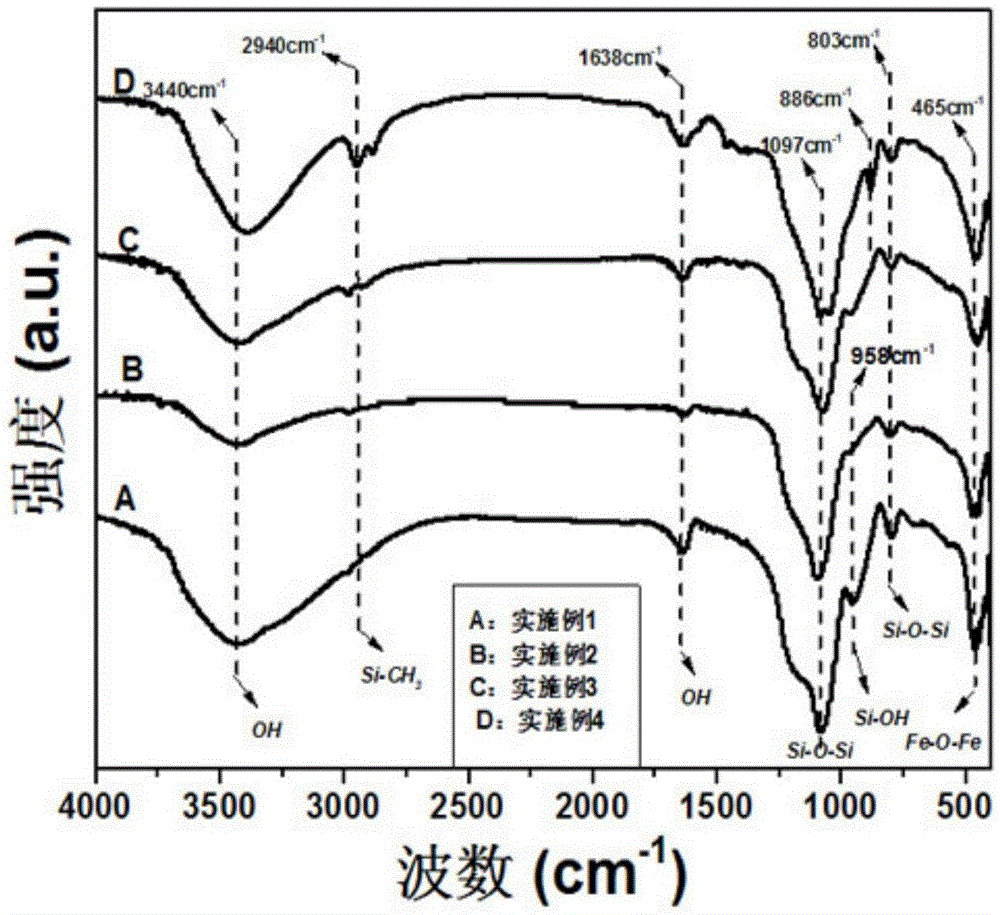

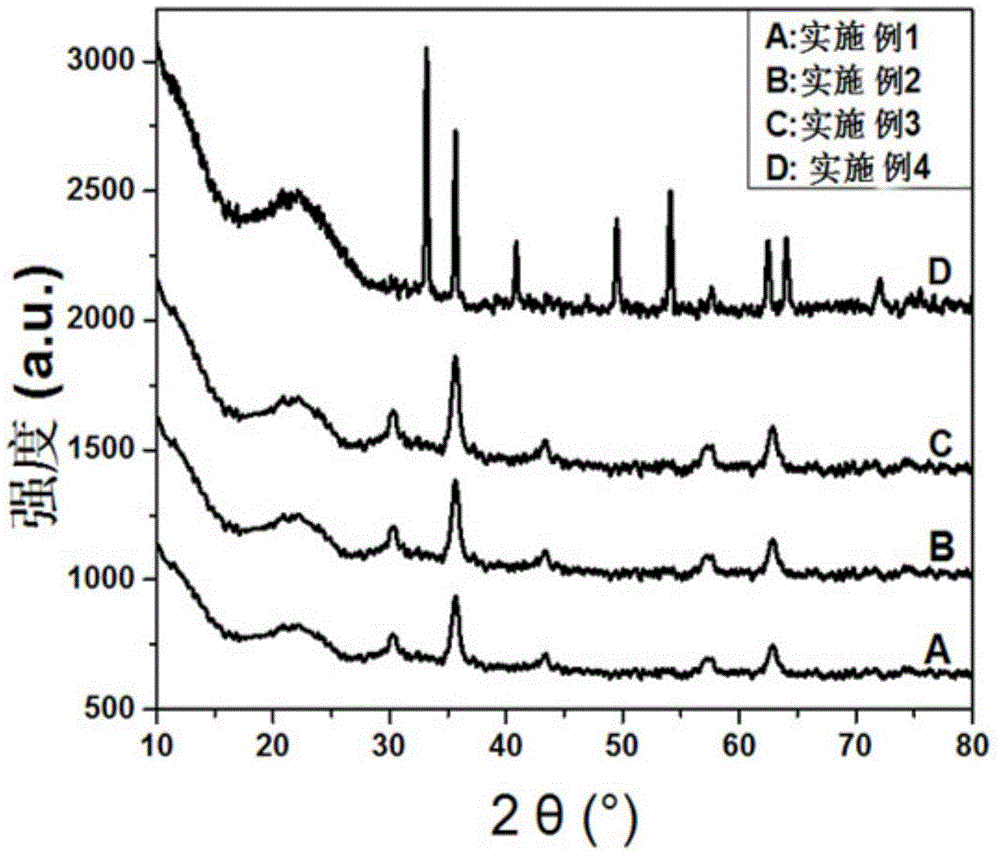

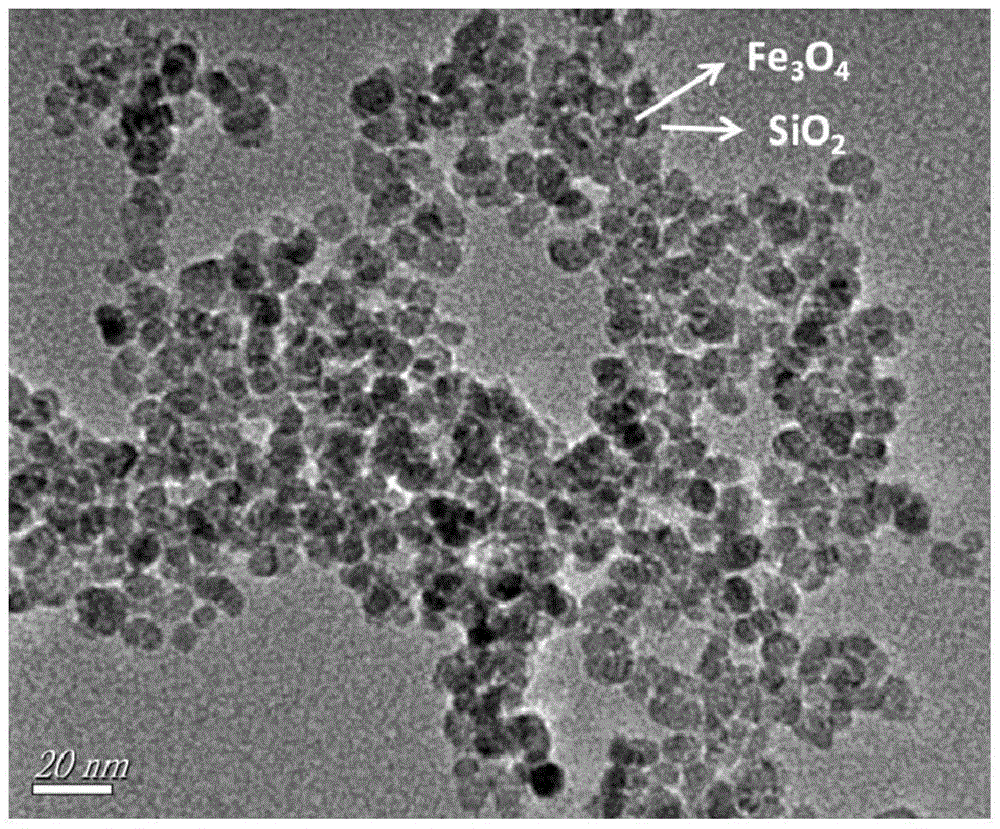

Embodiment 1

[0026] Weigh 0.433gFeCl 3 ·6H 2 O was dissolved in 3 mL ethanol and stirred until FeCl 3 ·6H 2 O was completely dissolved and 0.537 g H was added to the solution 2 O, then add 1.0g propylene oxide, stir vigorously for 3min, and let stand for 3min to 5min to form a brown-red gel. The gel was treated with TEOS, EtOH, H at 60°C 2 O is soaked in a mixed solution with a volume ratio of 10:9:1 for aging, and the solution is changed every 24 hours for a total of 6 times. The wet gel was placed in a 25mL polytetrafluoroethylene autoclave for solvothermal reaction, and 13mL of ethanol was added as a solvent for the solvothermal reaction. The reaction time was 24 hours and the reaction temperature was 200°C. After the reaction, it was naturally cooled to room temperature. The wet gel after the solvothermal reaction was soaked and washed with acetonitrile, and washed once every 12 hours, a total of 3 times. Place the washed wet gel in a vacuum drying oven at a controlled temperatu...

Embodiment 2

[0028] Weigh 0.433gFeCl 3 ·6H 2 O was dissolved in 3 mL ethanol and stirred until FeCl 3 ·6H 2 O was completely dissolved and 0.537 g H was added to the solution 2 O, then add 1.0g propylene oxide, stir vigorously for 3min, and let stand for 3min to 5min to form a brown-red gel. The gel was treated with TEOS, EtOH, H at 60°C 2O is soaked in a mixed solution with a volume ratio of 10:9:1 for aging, and the solution is changed every 24 hours for a total of 6 times. The wet gel was placed in a 25mL polytetrafluoroethylene autoclave for solvothermal reaction, and 13mL of ethylene glycol was added as a solvent for the solvothermal reaction. The reaction time was 24h and the reaction temperature was 200°C. After the reaction, it was naturally cooled to room temperature. The wet gel after the solvothermal reaction was soaked and washed with acetonitrile, and washed once every 12 hours, a total of 3 times. Place the washed wet gel in a vacuum drying oven at a controlled tempera...

Embodiment 3

[0030] Weigh 0.433gFeCl 3 ·6H 2 O was dissolved in 3 mL ethanol and stirred until FeCl 3 ·6H 2 O was completely dissolved and 0.537 g H was added to the solution 2 O, then add 1.0g propylene oxide, stir vigorously for 3min, and let stand for 3min to 5min to form a brown-red gel. The gel was treated with TEOS, EtOH, H at 60°C 2 O is soaked in a mixed solution with a volume ratio of 10:9:1 for aging, and the solution is changed every 24 hours for a total of 6 times. The wet gel was placed in a 25mL polytetrafluoroethylene autoclave for solvothermal reaction, and 13mL of tert-butanol was added as a solvent for the solvothermal reaction. The reaction time was 24 hours and the reaction temperature was 200°C. After the reaction, it was naturally cooled to room temperature. The wet gel after the solvothermal reaction was soaked and washed with acetonitrile, and washed once every 12 hours, a total of 3 times. Place the washed wet gel in a vacuum drying oven at a controlled temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com