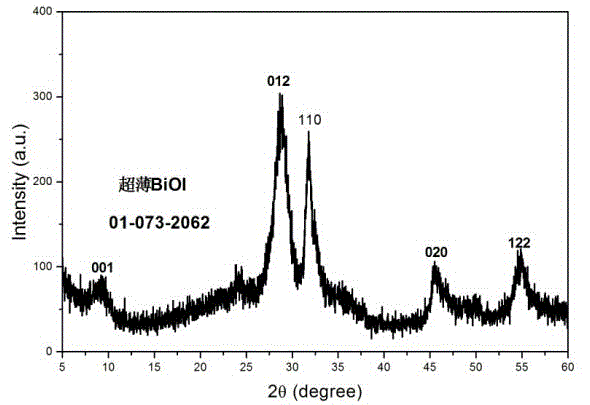

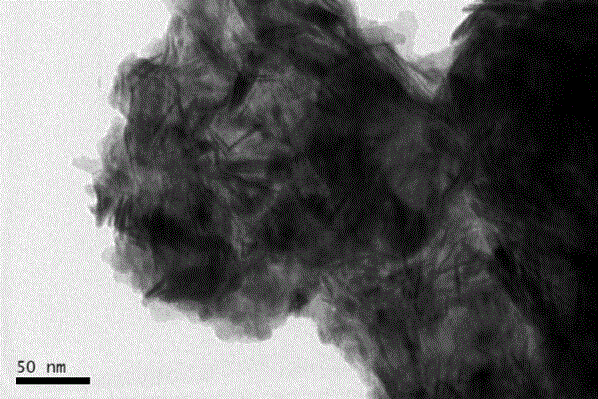

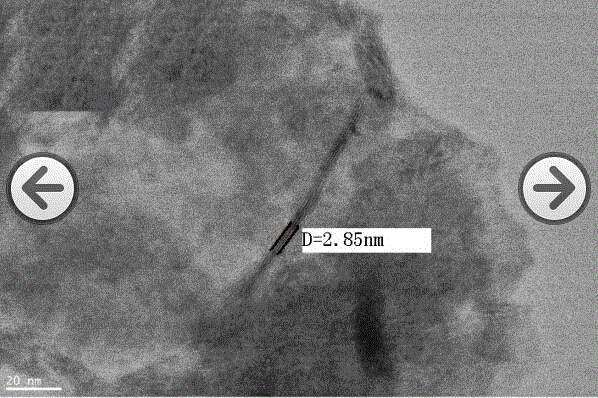

Defect-rich ultra-thin bismuth oxyiodide nano-sheet preparation method

A technology of bismuth iodide and nanosheets is applied in the field of preparation of ultra-thin bismuth iodide nanosheets and achieves the effects of increased photocatalytic activity, good light absorption efficiency and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 3.61g of bismuth nitrate pentahydrate and dissolve in 40mL of ethylene glycol, weigh 1.66g of potassium iodide and dissolve in 40mL of ethylene glycol, mix the two slowly, then add 1mL of benzaldehyde, and stir magnetically for 1h. The mixed solution was transferred to a hydrothermal reactor, and reacted for 18h at 160°C. After the reaction is completed, the hydrothermal reaction kettle is cooled to room temperature, and then the olive-green product in the hydrothermal reaction kettle is washed three times with ethanol and deionized water respectively, and dried. The obtained defect-rich ultrathin bismuth oxyiodide nanosheets exhibit high photocatalytic activity.

Embodiment 2

[0023] Weigh 3.61g of bismuth nitrate pentahydrate and dissolve in 40mL of ethylene glycol, weigh 1.66g of sodium iodide and dissolve in 40mL of ethylene glycol, mix the two slowly, then add 20mg of glucose, and stir magnetically for 1h. The mixed solution was transferred to a hydrothermal reactor, and reacted for 18h at 160°C. After the reaction is completed, the hydrothermal reaction kettle is cooled to room temperature, and then the olive-green product in the hydrothermal reaction kettle is washed three times with ethanol and deionized water respectively, and dried. The obtained defect-rich ultrathin bismuth oxyiodide nanosheets exhibit high photocatalytic activity.

Embodiment 3

[0025] Weigh 3.61g of bismuth nitrate pentahydrate and dissolve in 40mL of ethylene glycol, weigh 1.66g of potassium iodide and dissolve in 40mL of ethylene glycol, mix the two slowly, then add 1mL of benzaldehyde, and stir magnetically for 1h. The mixed solution was transferred to a hydrothermal reactor, and reacted for 24h at 140°C. After the reaction is completed, the hydrothermal reaction kettle is cooled to room temperature, and then the olive-green product in the hydrothermal reaction kettle is washed three times with ethanol and deionized water respectively, and dried. The obtained defect-rich ultrathin bismuth oxyiodide nanosheets exhibit high photocatalytic activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com