Ammonia-nitrogen removing method for treating high-concentration ammonia-nitrogen waste water

An ammonia nitrogen wastewater, high concentration technology, applied in separation methods, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of free ammonia inhibiting microbial activity, low ammonia nitrogen removal efficiency, and increasing oxygen supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

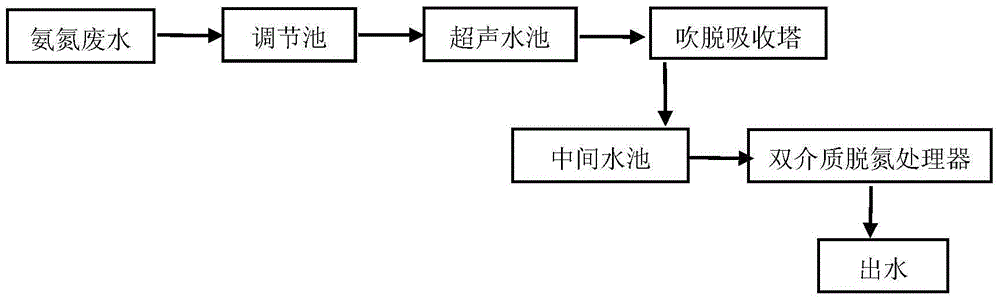

[0032] The following is a detailed description of the general process of high-concentration ammonia-nitrogen wastewater treatment combined with ultrasonic stripping method and biological nitrogen removal method in combination with the ammonia nitrogen wastewater treatment flow chart.

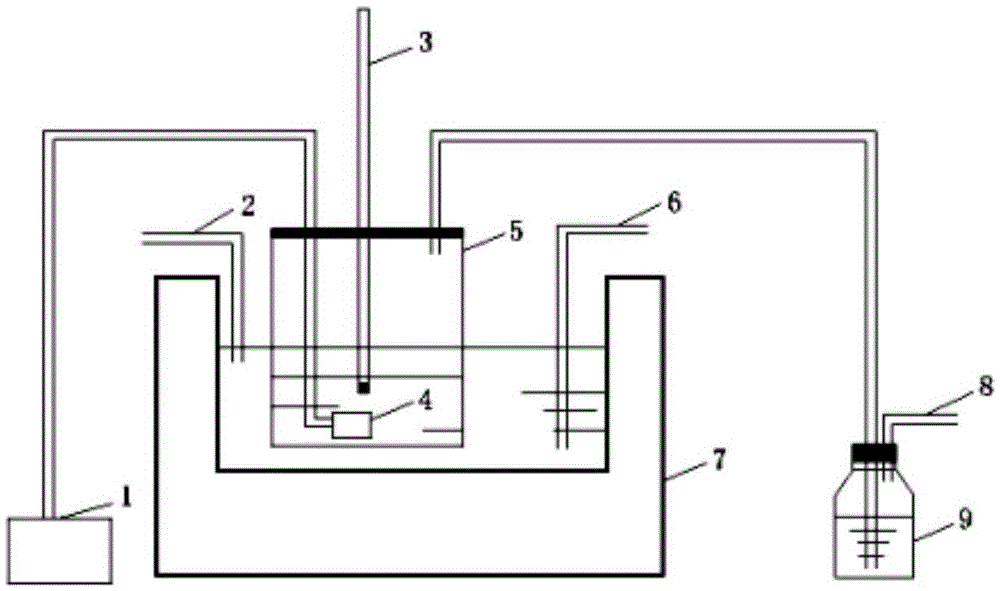

[0033] figure 1 As shown, 1-air pump, 2-outlet pipe, 3-thermometer, 4-aeration head, 5-beaker, 6-inlet pipe, 7-ultrasonic generator, 8-exhaust pipe, 9-absorption bottle.

[0034] Pretreatment stage: After the high-concentration ammonia-nitrogen wastewater enters the regulating tank, it is lifted by the pump to the ultrasonic pool, the steam is heated and due to the cavitation of the ultrasonic generator, the ammonia-nitrogen wastewater can be converted into ammonium salt to the maximum under the ultrasonic treatment Gaseous ammonia (free ammonia) greatly improves the subsequent ammonia nitrogen stripping treatment effect. After steam heating and ultrasonic action, the sewage is lifted to the ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com