Method for removing high ammonia nitrogen from pig farm dry manure cleaning livestock wastewater

A technology for aquaculture wastewater and dry cleaning of manure, which is applied in chemical instruments and methods, animal husbandry wastewater treatment, multi-stage water treatment, etc. Low and ensure the effect of up-to-standard emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

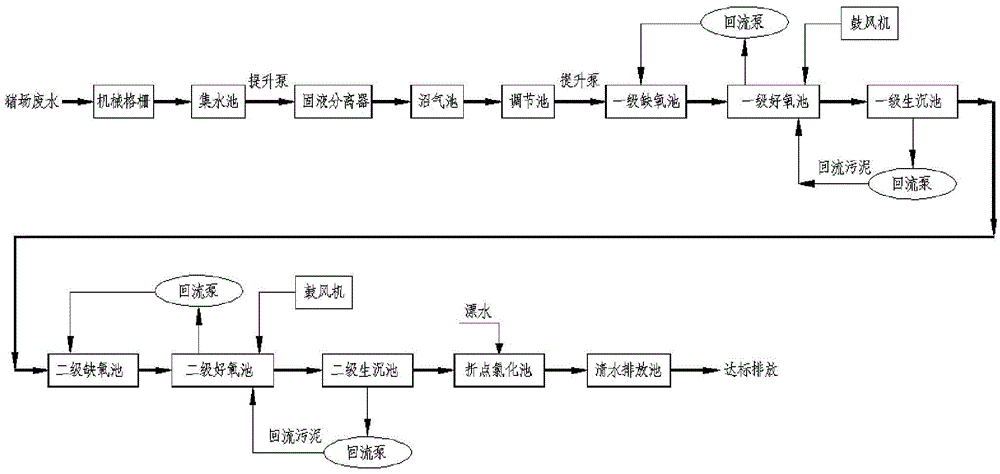

[0023] like figure 1 Shown, a kind of removal method of high ammoniacal nitrogen in the waste water of pig farm dry cleaning manure breeding, it comprises the steps:

[0024] In step (1), the pig-raising wastewater discharged from the pig house first passes through mechanical grilles to remove large particles, and then flows into the sump. Driven by the lift pump, it enters the solid-liquid separator for solid-liquid separation, and most of the wastewater is separated. Suspended matter such as small particles of dung and slag to remove part of the ammonia nitrogen and obtain waste water after slag separation.

[0025] In step (2), the waste water after slag separation enters the biogas digester for anaerobic fermentation, then enters the adjustment pond, and then enters the primary anoxic pond, where it is mixed with the mixed solution from the primary aerobic pond for denitrification. Then, the effluent from the first-level anoxic tank enters the first-level aerobic tank, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com