Synthetic method of guanethidine subplate drug intermediate cycloheptanone

A technology of guanethidine sulfate and its synthesis method, which is applied in the field of synthesis of cycloheptanone, a pharmaceutical intermediate of guanethidine sulfate, can solve the problems of slow onset of action, reduce intermediate links, reduce reaction temperature and reaction time, The effect of increasing the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

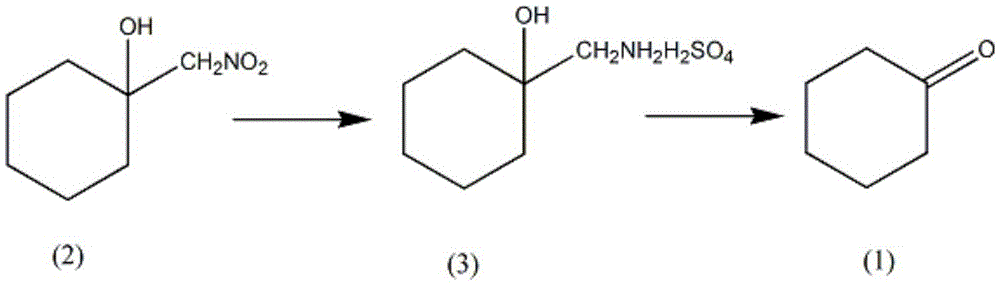

Method used

Image

Examples

example 1

[0012] (i) In a reaction vessel equipped with a stirrer, a thermometer, and a dropping funnel, add 500ml of water, 1.5mol of aluminum powder, and a phosphoric acid solution with a mass fraction of 40%, so that the temperature of the solution is controlled at 60°C, and dropwise add nitromethyl Cycloethanol 1.2mol, after adding, keep the solution temperature at 40°C, add 30mL sulfuric acid solution with a mass fraction of 40% every 30min, add 3 times in total, keep the pH of the solution at 3 for 1h, then filter, the filtrate is aminomethyl Cycloethanoic aluminum sulfate solution, the filtrate cake is used for the next batch after being washed with solvent methanol;

[0013] (ii) Use sulfuric acid to adjust the pH of the solution to 2 °C, slowly add 1.5 mol of sodium sulfite dissolved in 200 ml of water to form a solution, control the reaction temperature at 3 °C, keep the constant temperature for 20 minutes after adding, and then raise the temperature to 30 ℃, the reaction time...

example 2

[0015] (i) In a reaction vessel equipped with a stirrer, a thermometer, and a dropping funnel, add 550 ml of water, 1.5 mol of metal zinc powder, and a phosphoric acid solution with a mass fraction of 45%, so that the temperature of the solution is controlled at 65° C. Cycloethanol 1.2mol, after the addition, keep the solution temperature at 45°C, add 30mL of sulfuric acid solution with a mass fraction of 43% every 30min, add 3 times in total, keep the pH of the solution at 3 for 1h, then filter, the filtrate is ammonia Cycloethanoic zinc sulfate solution, the filtrate cake is used for the next batch after being washed with methyl ether solvent;

[0016] (ii) Use sulfuric acid to adjust the pH of the solution to 3, reduce the temperature of the solution to 4°C, slowly add 1.7mol of sodium sulfite dissolved in 200ml of water to form a solution, control the reaction temperature at 4°C, keep the constant temperature state for 20 minutes after adding, and then raise the temperature...

example 3

[0018] (i) In a reaction vessel equipped with a stirrer, a thermometer, and a dropping funnel, add 600ml of water, 1.5mol of metal aluminum powder, and a phosphoric acid solution with a mass fraction of 50%, so that the temperature of the solution is controlled at 70°C, and dropwise add nitrate Cycloethanol 1.2mol, after the addition, keep the solution temperature at 50°C, add 30mL sulfuric acid solution with a mass fraction of 45% every 30min, add 3 times in total, keep the pH of the solution at 4 for 1h, then filter, the filtrate is ammonia Cycloethanoic aluminum sulfate solution, the filtrate cake is used for the next batch after washing with methanol solvent;

[0019] (ii) Use sulfuric acid to adjust the pH of the solution to 3, reduce the temperature of the solution to 5°C, slowly add 2mol of sodium sulfite dissolved in 200ml of water to form a solution, control the reaction temperature at 5°C, keep the constant temperature state for 20 minutes after adding, and then raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com