Technology for producing nickel acetate through ion exchange method

An ion-exchange method and an ion-exchange technology are applied in the field of producing nickel acetate by ion-exchange method, can solve the problems such as the inability to realize continuous production, and achieve the effects of high strength, high content and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

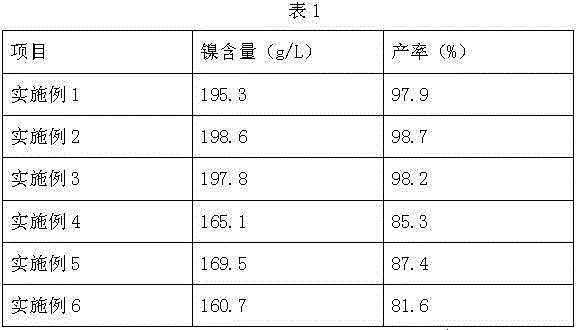

Examples

Embodiment 1

[0031] The technique of producing nickel acetate by ion exchange method comprises the following steps

[0032] Step 1: Resin Transformation

[0033] Sodium hydroxide is configured into a solution with a mass concentration of 5%. When the temperature of the solution drops below 40 degrees Celsius, the solution enters from the upper end of the ion exchange column at a speed of 2 m / hour and then recovers the outflowing solution for the next configuration of alkali Liquid, the transformation consumption of solution is the volume of 2 times of resin;

[0034] Step Two: Wash

[0035] Use deionized water with a conductivity of less than 10μs / cm to enter from the upper end of the ion exchange column to wash the lye in the ion exchange column, and the washing water is recovered for the preparation of lye;

[0036] Step Three: Ion Exchange

[0037] Pass the nickel salt solution of any concentration through the resin layer at a flow rate of 10 m / h in the ion exchange column, the sodiu...

Embodiment 2

[0056] The technique of producing nickel acetate by ion exchange method comprises the following steps

[0057] Step 1: Resin Transformation

[0058] Sodium carbonate is configured into a solution with a mass concentration of 10%. When the temperature of the solution drops below 40 degrees Celsius, the solution enters from the upper end of the ion exchange column at a speed of 4 m / hour and then recovers the outflowing solution for the next configuration of lye , the transformation consumption of solution is 2.5 times the volume of resin;

[0059] Step Two: Wash

[0060] Use deionized water with a conductivity of less than 10μs / cm to enter from the upper end of the ion exchange column to wash the lye in the ion exchange column, and the washing water is recovered for the preparation of lye;

[0061] Step Three: Ion Exchange

[0062] Pass the nickel salt solution of any concentration through the resin layer at a flow rate of 25 m / h in the ion exchange column, the sodium ions on...

Embodiment 3

[0075] The technique of producing nickel acetate by ion exchange method comprises the following steps

[0076] Step 1: Resin Transformation

[0077] Sodium carbonate is configured into a solution with a mass concentration of 20%. When the temperature of the solution drops below 40 degrees Celsius, the solution enters from the upper end of the ion exchange column at a speed of 5 m / hour and then recovers the outflowing solution for the next configuration of lye , the transformation consumption of solution is 3 times the volume of resin;

[0078] Step Two: Wash

[0079] Use deionized water with a conductivity of less than 10μs / cm to enter from the upper end of the ion exchange column to wash the lye in the ion exchange column, and the washing water is recovered for the preparation of lye;

[0080] Step Three: Ion Exchange

[0081] Pass the nickel salt solution of any concentration through the resin layer at a flow rate of 40 m / h in the ion exchange column, the sodium ions on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com