High-strength low-covering-thickness high-grade nano finish paint for vehicles and preparation method thereof

A low-coverage, high-strength technology, used in coatings, anti-corrosion coatings, etc., to solve problems such as high cover thickness and poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

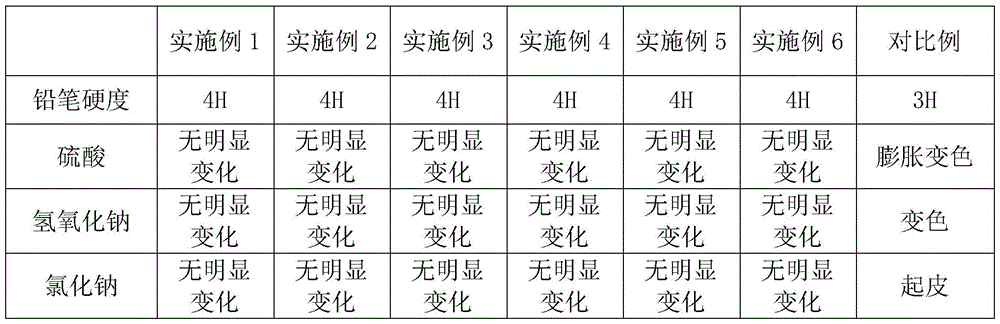

Examples

Embodiment 1

[0028] High-strength, low-coverage high-grade automotive nano-finish paint, including the following components in parts by weight: 54 parts of silicone acrylic resin, 4.5 parts of polycarboxylate ammonium salt, 1 part of acrylic defoamer, 0.9 part of hydrogenated castor oil , 7.2 parts of mixed solvent mixed with xylene and cyclohexanone with a mass ratio of 1:2, 3.5 parts of zinc naphthenate, 0.2 part of polyurethane thickener, 0.2 part of salicylic acid ultraviolet absorber, 0.7 part of propylene glycol 12 parts, 12 parts of composite nano zinc silicon iron powder, 3.5 parts of ammonium octanoate.

[0029] The steps of its preparation method are as follows:

[0030] (1) Add nano-iron oxide into deionized water, stir ultrasonically for 40 minutes until uniformly dispersed, add CTAB, tetraethyl orthosilicate, isopropanol, and ammonia water, heat to 45°C and stir for 10 hours, filter and add ammonium nitrate In the ethanol solution, heat to 90°C and reflux at a constant temper...

Embodiment 2

[0035]High-strength, low-coverage high-grade automotive nano-finish paint, including the following components in parts by weight: 52 parts of silicone acrylic resin, 5 parts of polycarboxylate ammonium salt, 2 parts of acrylic defoamer, 0.4 part of hydrogenated castor oil , 7.7 parts of mixed solvent mixed with xylene and cyclohexanone with a mass ratio of 1:2, 3.2 parts of zinc naphthenate, 0.3 part of polyurethane thickener, 0.4 part of salicylic acid ultraviolet absorber, 0.5 part of propylene glycol 14 parts, 14 parts of composite nano zinc silicon iron powder, 4 parts of ammonium octanoate.

[0036] Its preparation method is with embodiment 1.

Embodiment 3

[0038] High-strength, low-coverage high-grade automotive nano-finish paint, including the following components in parts by weight: 55 parts of silicone acrylic resin, 5.5 parts of polycarboxylate ammonium salt, 1.4 parts of acrylic defoamer, 0.6 part of hydrogenated castor oil , 7 parts of mixed solvent mixed with xylene and cyclohexanone with a mass ratio of 1:2, 4 parts of zinc naphthenate, 0.3 part of polyurethane thickener, 0.6 part of salicylic acid ultraviolet absorber, 0.3 part of propylene glycol 10 parts, 10 parts of composite nano zinc silicon iron powder, 3 parts of ammonium octanoate.

[0039] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com