Bi/Er or Bi/Er/Al co-doped quartz fiber and preparation method thereof

A quartz optical fiber and quartz material technology, which is applied in cladding optical fibers, glass optical fibers, glass manufacturing equipment, etc., can solve the problem of limiting the number of wavelength channels that quartz optical fibers can accommodate, and achieve simple structure, good uniformity, and high doping concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

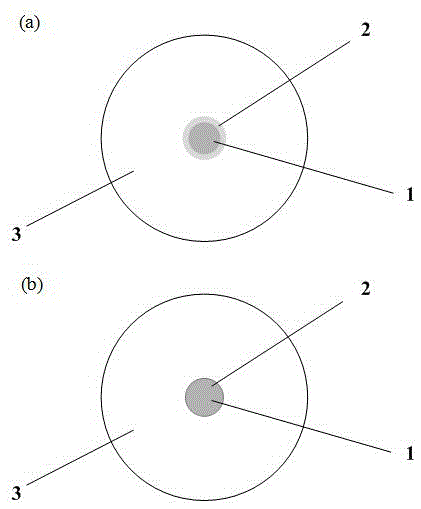

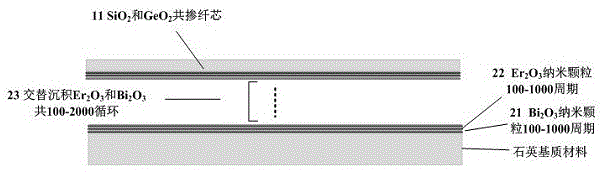

[0030] see figure 1 (a), a Bi / Er or Bi / Er / Al co-doped silica fiber, including a core 1, an inner cladding 2 and a cladding 3, the core 1 is made of GeO doped with a small amount of high refractive index 2 The inner cladding layer 2 is composed of Bi / Er or Bi / Er / Al co-doped ion material, and the inner cladding layer is deposited on the surface of the quartz substrate 21 by atomic layer deposition technology, and the inner cladding layer Bi / Er or Bi / Al Er / Al co-doped material composition. Deposit Al first 2 o 3 Nanoparticles 100 cycles with Bi 2 o 3 100 cycles of nanoparticles, the aluminum source precursor is trimethylaluminum Al(CH 3 ) 3 (TMA); the oxygen source precursor is ozone O 3 or deionized water H 2 O, Bi(thd) 3 is bi 2 o 3 The gas phase precursor material, the deposition temperature is 200 ℃; then, deposit Er 2 o 3 Nanoparticles 100 cycles, Er(thd) 3 and O 3 is used to deposit Er 2 o 3 The gas phase precursor, the deposition temperature range is 200°C...

Embodiment 2

[0032] see figure 1 (a), a Bi / Er or Bi / Er / Al co-doped silica fiber, including a core 1, an inner cladding 2 and a cladding 3, the core 1 is made of GeO doped with a small amount of high refractive index 2 The inner cladding layer 2 is composed of Bi / Er or Bi / Er / Al co-doped ion material, and the inner cladding layer is deposited on the surface of the quartz substrate 21 by atomic layer deposition technology, and the inner cladding layer Bi / Er or Bi / Al Er / Al co-doped material composition. Deposit Al first 2 o 3 Nanoparticles 1500 cycles with Bi 2 o 3 2000 cycles of nanoparticles, the aluminum source precursor is trimethylaluminum Al(CH 3 ) 3 (TMA); the oxygen source precursor is ozone O 3 or deionized water H 2 O, Bi(thd) 3 is bi 2 o 3 The gas phase precursor material of the deposition temperature is 300 °C; then, the deposition of Er 2 o 3 Nanoparticles 100 cycles, Er(thd) 3 and O 3 is used to deposit Er 2 o 3 The gas phase precursor, the deposition temperature...

Embodiment 3

[0034] see figure 1 (b), a Bi / Er or Bi / Er / Al co-doped silica fiber, including a core layer and a cladding layer 3, the core layer is made of GeO doped with a small amount of high refractive index 2 The quartz loose layer is composed of Bi / Er or Bi / Er / Al ion co-doped material, wherein Bi / Er or Bi / Er / Al ion is deposited by atomic layer deposition technology; Made of pure quartz material. Finally, it shrinks into a rod and draws it. Among them, the Bi / Er or Bi / Er / Al co-doped silica fiber is characterized in that the core and cladding diameter ranges are D core =Φ5μm, D cladding =Φ125μm, the refractive index difference between the core layer and the cladding layer is 0.35%. And the shape of the cladding can be a conventional doped silica amplifying fiber type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com