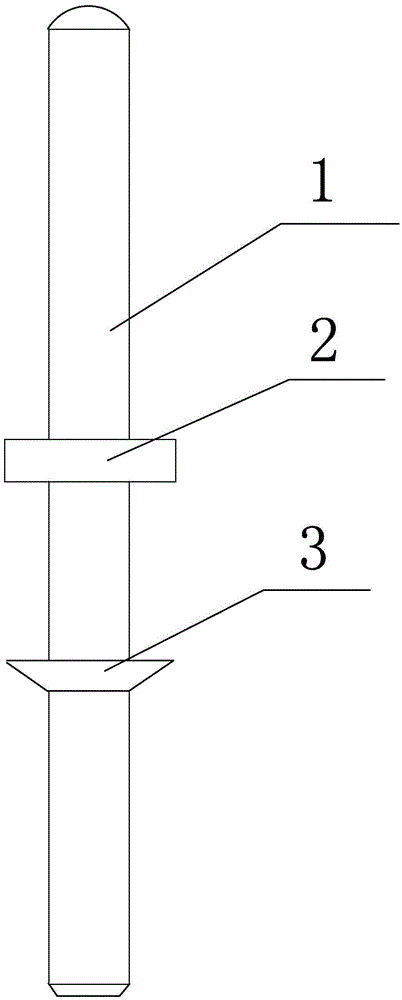

Connector used for lawn mower

A connector and lawn mower technology, applied in the direction of cutter, harvester, application, etc., can solve the problems of affecting the use of the connector, general thermal fatigue resistance, reducing the use efficiency and service life of the connector, etc. Fatigue resistance, improved strength and stress relaxation resistance, effect of increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

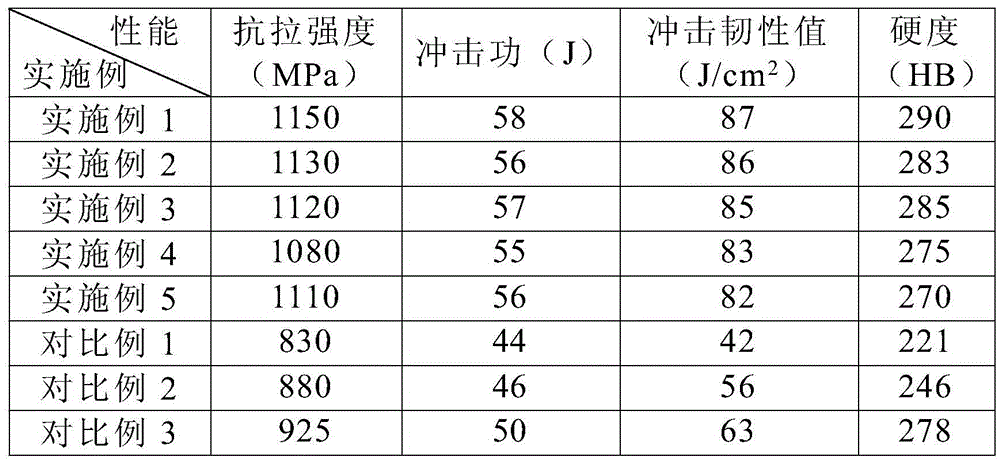

Embodiment 1

[0033] The carbon fiber coated with SiC coating on the surface is woven into three-dimensional braided carbon fiber (braiding angle is 20-35 degrees) through three-dimensional five-way mixing; SiC is coated on the carbon fiber by physical sputtering method, and the thickness of SiC coating is 0.8 μm ;

[0034] After the three-dimensional braided carbon fiber is fixed in the mold, pour the metal liquid formed by smelting the tin-phosphorus bronze alloy to obtain a semi-finished product of the three-dimensional braided carbon fiber / tin-phosphorus bronze composite material (the volume percentages of the three-dimensional braided carbon fiber and the tin-phosphorus bronze alloy in the composite material are respectively 8% and 92%); wherein, tin phosphor bronze consists of the following components by weight: Zn: 3.0%, Sn: 4.0%, P: 0.02%, Fe: 0.03%, Ni: 0.7%, Si: 0.07%, rare earth elements : 0.3%, Pb<0.02%, Al<0.002%, Sb<0.002%, Bi<0.002%, the balance is Cu and unavoidable impurity...

Embodiment 2

[0038] The carbon fiber coated with SiC coating on the surface is woven into three-dimensional braided carbon fiber (braiding angle is 20-35 degrees) through three-dimensional five-way mixing; SiC is coated on the carbon fiber by physical sputtering method, and the thickness of SiC coating is 1.0 μm ;

[0039] After the three-dimensional braided carbon fiber is fixed on the mould, pour the metal liquid formed by smelting the tin-phosphorus bronze alloy to obtain a semi-finished product of the three-dimensional braided carbon fiber / tin-phosphorus bronze composite material (the volume percentages of the three-dimensional braided carbon fiber and the tin-phosphorus bronze alloy in the composite material are respectively 6% and 94%); wherein, tin phosphor bronze is composed of the following components by weight: Zn: 3.2%, Sn: 3.8%, P: 0.025%, Fe: 0.02%, Ni: 0.8%, Si: 0.06%, rare earth elements : 0.4%, Pb<0.02%, Al<0.002%, Sb<0.002%, Bi<0.002%, the balance is Cu and unavoidable imp...

Embodiment 3

[0043] The carbon fiber coated with SiC coating on the surface is woven into a three-dimensional braided carbon fiber (braiding angle is 20-35 degrees) through three-dimensional five-way mixing; the carbon fiber is coated with SiC by physical sputtering method, and the thickness of the SiC coating is 0.7 μm ;

[0044] After the three-dimensional braided carbon fiber is fixed in the mold, pour the metal liquid formed by smelting the tin-phosphorus bronze alloy to obtain a semi-finished product of the three-dimensional braided carbon fiber / tin-phosphorus bronze composite material (the volume percentages of the three-dimensional braided carbon fiber and the tin-phosphorus bronze alloy in the composite material are respectively 7% and 93%); Among them, tin phosphor bronze is composed of the following components by weight: Zn: 2.8%, Sn: 4.2%, P: 0.015%, Fe: 0.04%, Ni: 0.6%, Si: 0.08%, rare earth elements : 0.2%, Pb<0.02%, Al<0.002%, Sb<0.002%, Bi<0.002%, the balance is Cu and unavo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com