Cataplasm and method for producing same

A manufacturing method and peg technology, which are applied in the field of peg and its manufacture, can solve problems such as decreased adhesion and inhibit the decline of adhesion, and achieve the effect of sufficient adhesion and maintenance of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Hereinafter, the poultry of the present invention will be described in detail using examples and test examples, but the present invention is not limited by the examples. In addition, unless otherwise specified, the content described in Tables 1-12 shows mass %. The preparation method of the poultry and the measurement method of the adhesive force in the Examples and Test Examples are as follows.

[0076] (Poultry preparation method)

[0077] Stir and mix the necessary ingredients for the prescribed time to obtain a paste. The obtained paste was evenly spread on the release liner so that the paste mass per sheet of poultice (140 mm×100 mm) was 5 g, and immediately thereafter, a nonwoven fabric was further laminated to prepare a poultice.

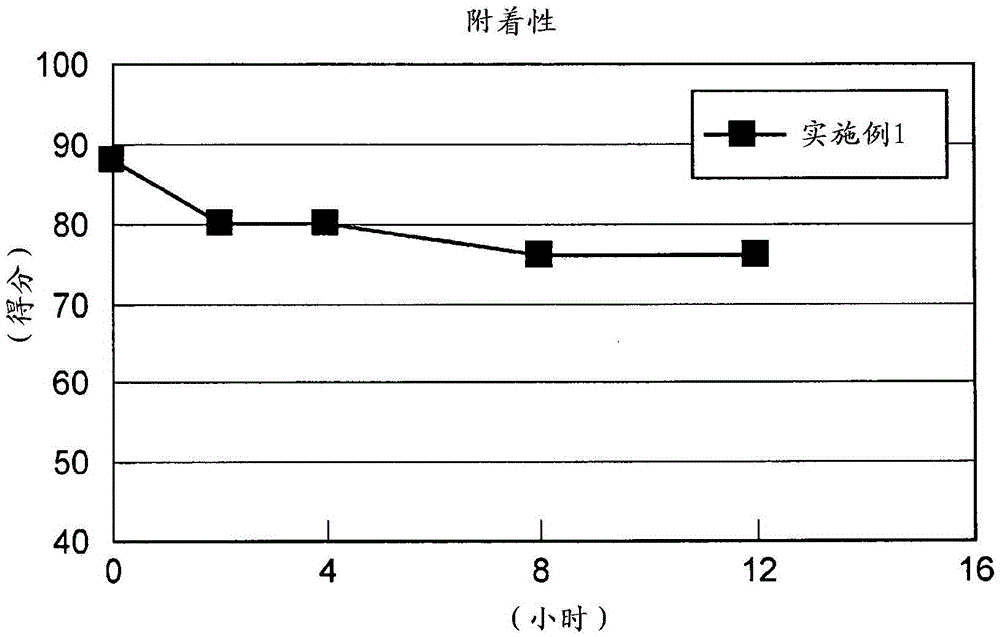

Embodiment 1

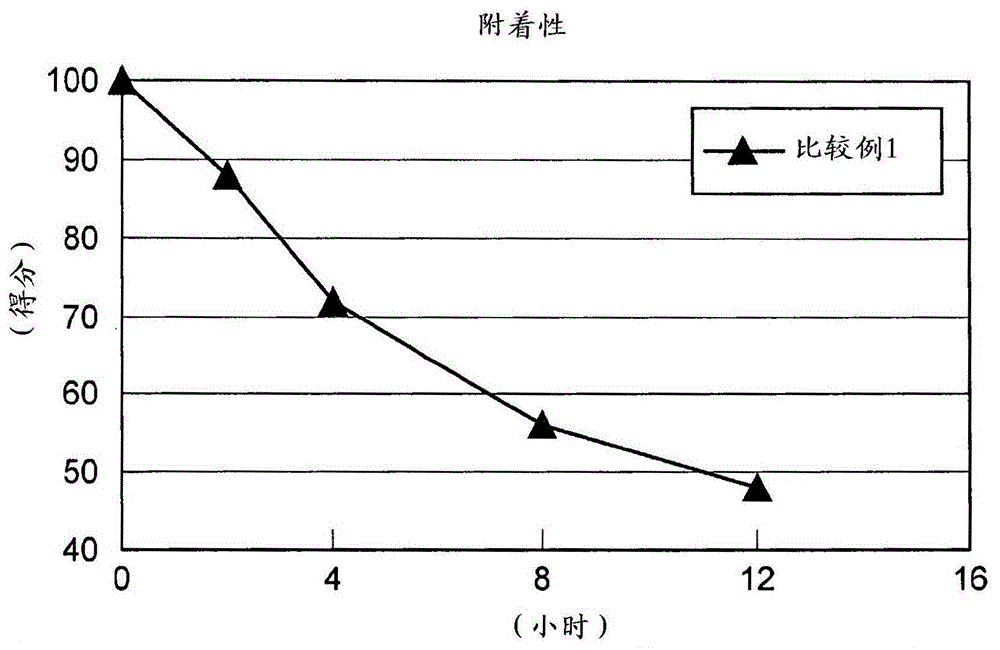

[0096] Time-dependent changes in the adhesive force of a cement compound containing a completely neutralized polyacrylic acid and a methyl acrylate-2-ethylhexyl acrylate copolymer emulsion

[0097] (1) Test sample

[0098] Using fully neutralized polyacrylic acid (trade name: VISCOMATEF480SS, manufactured by Showa Denko Co., Ltd.) instead of partially neutralized polyacrylic acid, mix 16.7% by mass of methyl acrylate·2-ethylhexyl acrylate copolymer resin emulsion (trade name: NIKASOLTS-620 (manufactured by Nippon Carbide Industries Co., Ltd.), 30% by mass of concentrated glycerin, and 37.8% by mass of purified water were followed in the same manner as in Comparative Example 1 to prepare a poultice (Example 1).

[0099] (2) Test method

[0100] The test was performed by the same method as [Comparative Example 1].

[0101] (3) Test results

[0102] Such as figure 2 As shown, the adhesion score of Comparative Example 2 was 90 immediately after application, and the adhesion s...

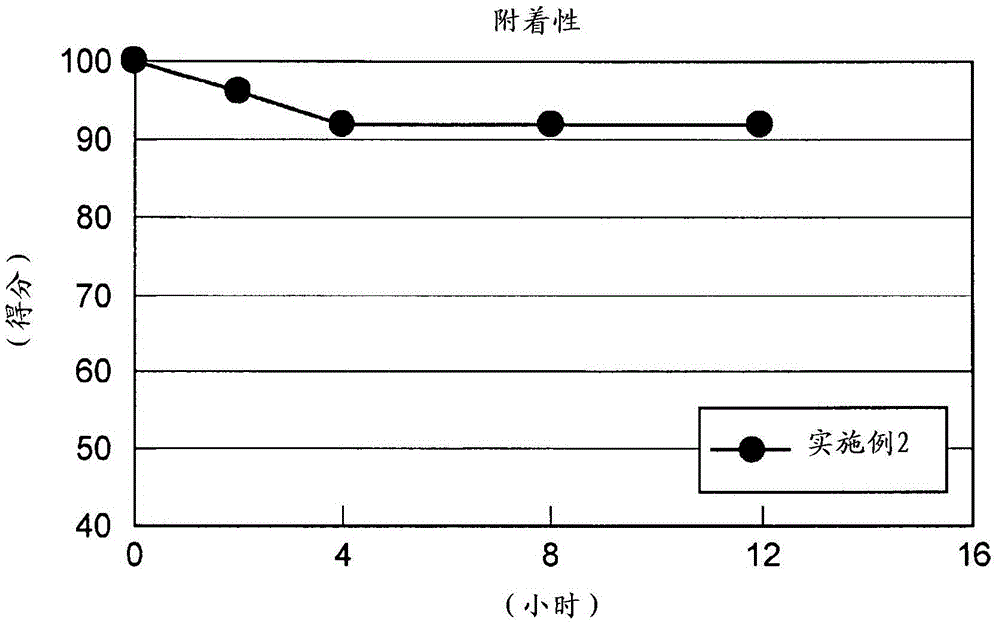

Embodiment 2

[0104] Time-dependent changes in the adhesive force of a poultry compounded with partially neutralized polyacrylic acid and methyl acrylate-2-ethylhexyl acrylate copolymer emulsion

[0105] (1) Test sample

[0106] Mix 16.7% by mass of methyl acrylate·2-ethylhexyl acrylate copolymer (trade name: NIKASOLTS-620, manufactured by Nippon Carbide Industry Co., Ltd.), 30% by mass of concentrated glycerin, and 37.8% by mass of purified water. Otherwise, it carried out similarly to the comparative example 1, and obtained the poultice (Example 2).

[0107] (2) Test method

[0108] The test was performed by the same method as [Comparative Example 1].

[0109] (3) Test results

[0110] Such as image 3 As shown, the adhesion score of Example 1 was 100 immediately after application, and the adhesion score decreased by about 9% after 12 hours from application. The adhesion score of Example 1 did not decrease from 4 hours to 12 hours after attachment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com