Method for making canned cherries

A technology for cherries and canned food, applied in the functions of food ingredients, preservation of food ingredients as antimicrobials, food preservation, etc., can solve the problems of short maturity period, damage and loss of nutrients, and impermanence, and prevent iron or cyanide. The effect of glycoside poisoning, promoting hemoglobin regeneration and preventing cherry aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

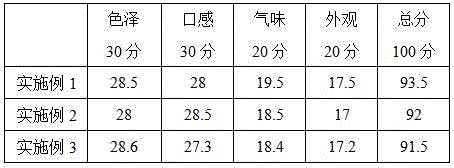

Examples

Embodiment 1

[0022] A preparation method of canned cherries, comprising the following steps:

[0023] 1) Select fresh cherries with uniform particles, bright color and plumpness, immerse in water, the weight ratio of cherries to water is 1:1.8, then add mixed enzyme with 4% of the mass of cherries, mix well, soak at 42-46°C for 4 day, take it out, wash it with water, and dry it in the air; the mixed enzymes are neutral cellulase, hemicellulase, pectinase and amylase; the neutral cellulase, hemicellulase, pectinase and amylase The mass ratio is 3:3:1.5:1;

[0024] 2) Immerse the cherries treated in step 1) in water again, the weight ratio of cherries to water is 1:1.2, add alkaline protease with 2.8% of the mass of cherries, heat up to 53°C for 9 hours, and continue to heat up to 102°C for 6 minutes , then lower the temperature to 30°C, add 0.8% lipase of cherry quality, keep it warm for 1-2 hours, then raise the temperature to 103°C and keep it warm for 7 minutes, take it out, wash it wit...

Embodiment 2

[0029] A preparation method of canned cherries, comprising the following steps:

[0030] 1) Select fresh cherries with uniform particles, bright color and plumpness, immerse in water, the weight ratio of cherries to water is 1:1.5, then add 3% mixed enzyme of cherry mass, mix well, soak at 38°C for 3 days, Take it out, wash it with clear water, and dry it in the air; the mixed enzymes are neutral cellulase, hemicellulase, pectinase and amylase; the quality of the neutral cellulase, hemicellulase, pectinase and amylase The ratio is 3:3:1.5:1;

[0031] 2) Immerse the cherries treated in step 1) in water again, the weight ratio of cherries to water is 1:1, add alkaline protease with 2.5% of the mass of cherries, heat up to 50°C for 8 hours, and continue to heat up to 100°C for 5 minutes , then lower the temperature to 30°C, add 0.5% lipase of cherry mass, keep it warm for 1h, then raise the temperature to 100°C and keep it warm for 5min, take it out, wash it with clean water, an...

Embodiment 3

[0036] A preparation method of canned cherries, comprising the following steps:

[0037] 1) Select fresh cherries with uniform particles, bright color and plumpness, immerse in water, the weight ratio of cherries to water is 1:2, then add 5% mixed enzyme of cherry mass, mix well, soak at 46°C for 5 days, Take it out, wash it with clear water, and dry it in the air; the mixed enzymes are neutral cellulase, hemicellulase, pectinase and amylase; the quality of the neutral cellulase, hemicellulase, pectinase and amylase The ratio is 3:3:1.5:1;

[0038] 2) Immerse the cherries treated in step 1) in water again, the weight ratio of cherries to water is 1:1.5, add alkaline protease with 3% of the mass of cherries, heat up to 55°C for 10 hours, and continue to heat up to 105°C for 8 minutes , then lower the temperature to 30°C, add lipase with 1% of the mass of cherries, keep it warm for 2 hours, then raise the temperature to 105°C and keep it warm for 8 minutes, take it out, wash it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com