Preparation method of reagent-grade stannous chloride dehydrate crystals

A stannous chloride and dihydrate technology, applied in the directions of stannous chloride, tin halide, etc., can solve the problems of unenvironmental protection, high corrosiveness and large acid loss in the production process, and achieve easy control of process parameters and strong market competition. force, the effect of environmental protection in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

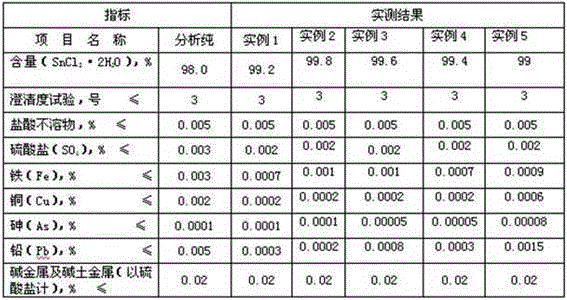

Embodiment 1

[0024] Add 1,300 kg of the above-mentioned pretreated industrial hydrochloric acid into the enamel reaction kettle, start stirring, add tin hydroxide with a metal tin content of 300 kg, raise the temperature to 90°C, stir and react for 30 minutes, the tin hydroxide is completely dissolved, and add the above pretreated The final tin flower is 330 kg (the molar ratio of tin hydroxide to tin ingot is 1:1.1). After heating up to 95°C, heat preservation reaction for 12 hours. The appearance of the solution is colorless and transparent. The content of tetravalent tin is tested by sampling, and the test result is 0.01 %, concentrate the solution under reduced pressure to a specific gravity of 2.0, filter to a cooling crystallizer, cool at 0°C for 24 hours, cut the material, vacuum filter, and centrifuge for 15 minutes to obtain stannous chloride dihydrate crystals. The actual measurement results of various indicators See Schedule.

Embodiment 2

[0026] Add 1,400 kg of the above-mentioned pretreated industrial hydrochloric acid and the stannous chloride mother liquor obtained in Example 1 into the enamel reaction kettle, start stirring, add tin hydroxide with a metal tin content of 300 kg, heat up to 95°C, and stir until hydrogen The tin oxide is completely dissolved, add 390 kg of tin flower after the above pretreatment (the molar ratio of tin hydroxide to tin ingot is 1:1.3), raise the temperature to 100°C and keep it warm for 15 hours. The appearance of the solution is colorless and transparent. Tetravalent tin content, the test result is 0.005%, the solution is concentrated under reduced pressure to a specific gravity of 2.1, filtered to a cooling crystallizer, cooled at 5°C for 18 hours, fed, vacuum filtered, and centrifuged for 12 minutes to obtain chlorine dihydrate For stannous crystal, the measured results of various indicators are shown in the attached table.

Embodiment 3

[0028] Add 1,500 kg of the above-mentioned pretreated industrial hydrochloric acid and the stannous chloride mother liquor obtained in Example 2 into the enamel reaction kettle, start stirring, add tin hydroxide with a metal tin content of 300 kg, heat up to 105°C, and stir until hydrogen The tin oxide is completely dissolved, add 450 kg of tin flower after the above pretreatment (the molar ratio of tin hydroxide to tin ingot is 1:1.5), heat up to 105°C and keep it warm for 18 hours. The appearance of the solution is colorless and transparent, take a sample for inspection Tetravalent tin content, the test result is 0.01%, the solution is concentrated under reduced pressure to a specific gravity of 2.4, filtered to a cooling crystallizer, cooled at 10°C for 16 hours, fed, vacuum filtered, and centrifuged for 10 minutes to obtain chlorine dihydrate For stannous crystal, the measured results of various indicators are shown in the attached table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com