Separation and purification method of salvianolic acid B and preparation method of salvianolic acid B magnesium salt

A technology for separation and purification of salvianolic acid, applied in the field of separation and purification of salvianolic acid B, can solve the problems of limited use of high-speed countercurrent chromatography, cumbersome operation process, complicated process, etc., and achieve time-saving purification methods, high purity, and purification methods simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

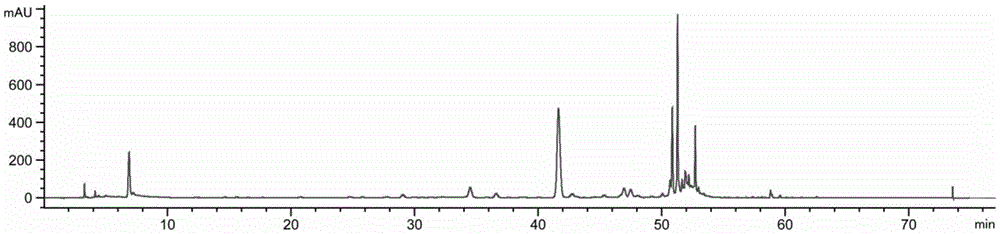

[0038] Embodiment 1: the preparation of high-purity salvianolic acid A

[0039] (1) Extraction of salvianolic acid B: Take about 500g of salvia miltiorrhiza medicinal material powder, add 75wt% ethanol, the mass ratio of salvia miltiorrhiza medicinal material powder to ethanol is 1:12g / mL; ultrasonic extraction 2 times, 30 minutes each time, filter , combined the filtrates, concentrated under reduced pressure, added an appropriate amount of water to the concentrated solution, extracted an equal volume of dichloromethane to remove impurities, adjusted the pH of the aqueous layer to 2 with 2.5N hydrochloric acid, and extracted twice with an equal volume of ethyl acetate. The ethyl acetate extract was concentrated under reduced pressure to obtain the crude extract of salvianolic acid B.

[0040] (2) Magnesium salt complexation purification: NaHCO 3 with MgCl 2Add the solution with a molar ratio of 2:1 into the crude extraction of salvianolic acid B to dissolve it, extract twice...

Embodiment 2

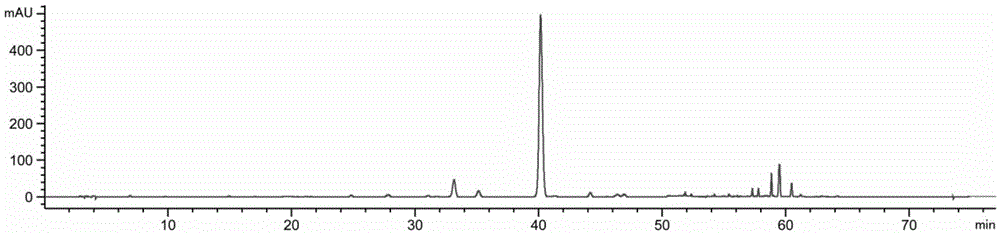

[0045] Embodiment 2: preparation of salvianolic acid B magnesium salt

[0046] Take MgCl 2 Soluble in distilled water, prepared to a concentration of 1wt% MgCl 2 aqueous solution, then dropwise add 1wt% NaOH aqueous solution until no white precipitate is generated, filter the precipitate, wash the precipitate with distilled water until neutral; take Mg(OH) 2 Add water, pass CO 2 60-90min until the solution is clear, and ultrasonic for 10min to remove excess CO in the solution 2 , the solution is filtered to remove insoluble particles, and the magnesium bicarbonate solution is obtained; the magnesium bicarbonate solution must be prepared immediately after use.

[0047] Add 20 mg of the 98% salvianolic acid B sample prepared in Example 1 into the freshly prepared magnesium bicarbonate solution, and shake to dissolve it. Extract with an equal volume of ethyl acetate, combine the extracts, concentrate under reduced pressure and evaporate to dryness to obtain high-purity salvia...

Embodiment 3

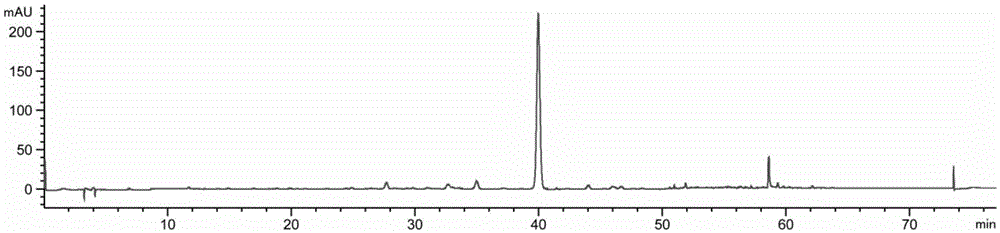

[0048] Embodiment 3: preparation of salvianolic acid B magnesium salt

[0049] Take MgCl 2 Soluble in distilled water, formulated to a concentration of 0.05wt% MgCl 2 Aqueous solution; The 98% salvianolic acid B sample 20mg that embodiment 1 prepares joins MgCl 2 In aqueous solution, stirring at room temperature, NaHCO was added dropwise 3 Aqueous solution; after the dropwise addition, filter with suction and freeze-dry to obtain salvianolic acid B magnesium salt complex.

[0050] The MgCl 2 MgCl contained in the solution 2 The ratio of the number of moles to the number of moles of salvianolic acid B is 1:2. Among them, the NaHCO 3 NaHCO contained in the solution 3 The molar ratio of the moles of salvianolic acid B and salvianolic acid B is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com