Preparation method of tackifier for addition type liquid silicone rubber

A liquid silicone rubber and tackifier technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reducing LED life, yellowing, reducing LED light efficiency, etc., to achieve compatibility Good, excellent adhesive strength, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

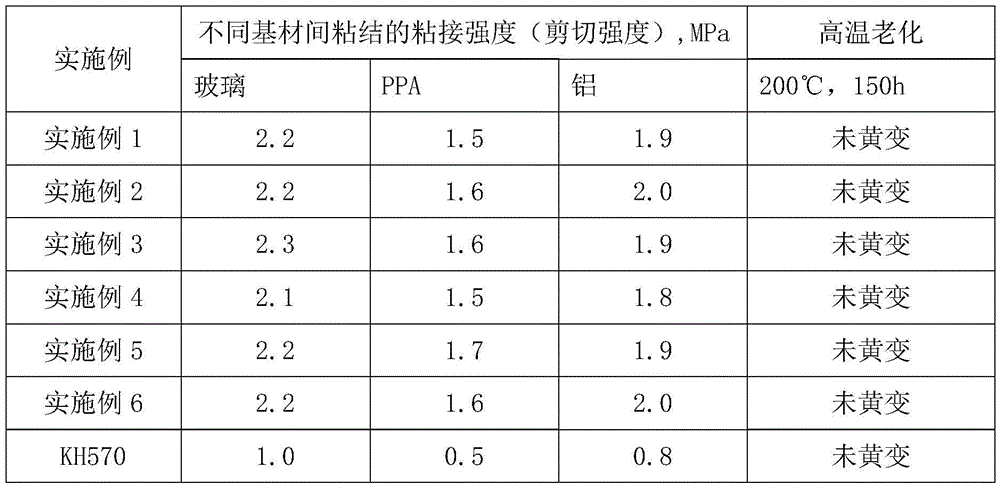

Examples

Embodiment 1

[0020] Under a nitrogen atmosphere and an ice-water bath, add 20 parts of methacryloxypropyltrimethoxysilane, 100 parts of tetramethylcyclotetrasiloxane, and 0.1 part of chloroplatinic acid catalyst into the reactor, and stir evenly; While stirring, slowly add 30 parts of vinyltrimethoxysilane dropwise, after 0.5h, the dropwise addition is completed, and the reaction is stirred at a constant temperature for 1.0h; the temperature rise rate is controlled at 1.0°C / min, the temperature is raised to 40°C, and the reaction is stirred at a constant temperature for 6.0h; Under a vacuum of 0.04MPa, the temperature was further raised to 100°C, and the temperature was lowered until no fraction flowed out. Stop vacuuming, stop stirring, fill with nitrogen, cool down to room temperature, and obtain the expected tackifier. The stirring rate of the whole reaction was 200r / min.

Embodiment 2

[0022] Under a nitrogen atmosphere and an ice-water bath, add 50 parts of methacryloxypropyltrimethoxysilane, 140 parts of tetramethylcyclotetrasiloxane, and 0.3 parts of chloroplatinic acid catalyst into the reactor, and stir evenly; At the same time, 50 parts of vinyltriethoxysilane was slowly added dropwise, and the dropwise addition was completed for 1.0h, and the reaction was stirred at a constant temperature for 3.0h; the temperature increase rate was controlled at 1.0°C / min, and the temperature was raised to 70°C, and the reaction was stirred at a constant temperature for 2.0h; Under the vacuum degree of 0.06MPa, the temperature was further raised to 80, and the temperature was lowered until no fraction flowed out. Stop vacuuming, stop stirring, fill with nitrogen, cool down to room temperature, and obtain the expected tackifier. The stirring rate of the whole reaction was 250r / min.

Embodiment 3

[0024] Under a nitrogen atmosphere and an ice-water bath, add 40 parts of methacryloxypropyltrimethoxysilane, 130 parts of hydrogen-containing silicone oil or tetramethylcyclotetrasiloxane, and 0.2 parts of chloroplatinic acid catalyst into the reactor, and stir Evenly; while stirring, slowly add 45 parts of vinyltriacetoxysilane dropwise, 1.0h after the dropwise addition, and keep stirring for 2.0h at a constant temperature; control the heating rate at 1.0°C / min, raise the temperature to 65°C, and stir at a constant temperature for 2.5 h; under the vacuum degree of -0.04MPa, the temperature was further raised to 100°C, and the temperature was lowered until no fraction flowed out. Stop vacuuming, stop stirring, fill with nitrogen, cool down to room temperature, and obtain the expected tackifier. The stirring rate of the whole reaction was 250r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com