Multistage fermentation device containing fermentation liquor reflux and denitrification system

A fermentation device and fermentation system technology, applied in the field of biomass resource utilization, can solve problems such as the inability of biogas projects to run stably, and achieve the effects of prolonging the number of biogas slurry reflux, improving utilization ratio, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

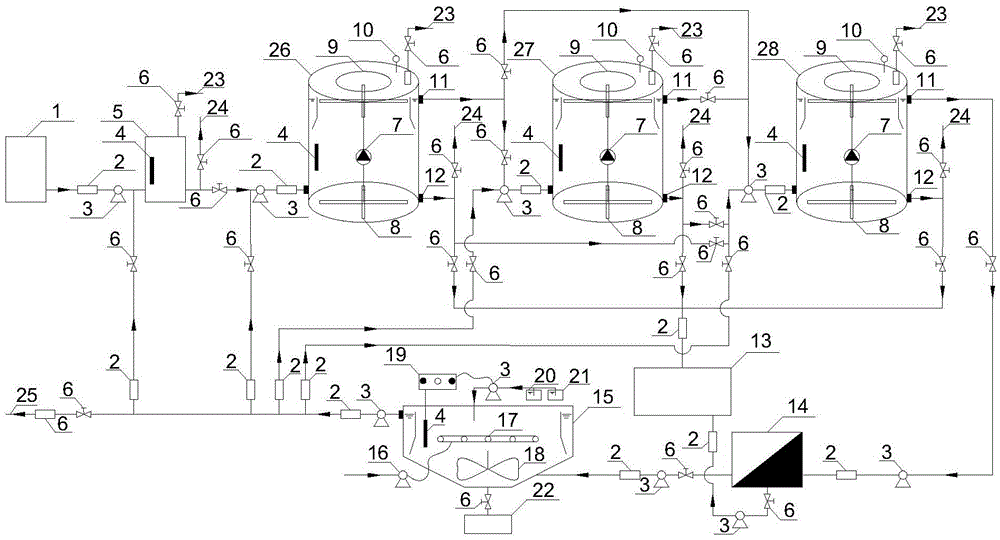

[0038] Use the above-mentioned anaerobic fermentation device to treat the food waste generated in a canteen. Before the food waste enters the anaerobic fermentation system, it is pretreated to remove bones, peels, plastic bags, etc. with large particle sizes. The sorted food waste is crushed and mixed with a mixer, then mixed with the refluxing biogas slurry, and then enters the mixing and feeding device 5, and the pH of the fermentation feed liquid is adjusted to 6-6.5. The regulated fermentation feed liquid enters the No. 1 fermentation tank 26 through the valve 6, the pump 3 and the flow meter 2 for fermentation. The hydraulic retention time of the fermentation feed liquid in the No. 1 fermenter 26 is 1 day. The fermented liquid produced by the No. 1 fermenter 26 enters the No. 2 fermenter 27 through the fermented liquid outlet 11, valve 6, pump 3 and flowmeter 2 for fermentation. The hydraulic retention time of the fermented liquid in No. 2 fermenter 27 is 8 days. The f...

Embodiment 2

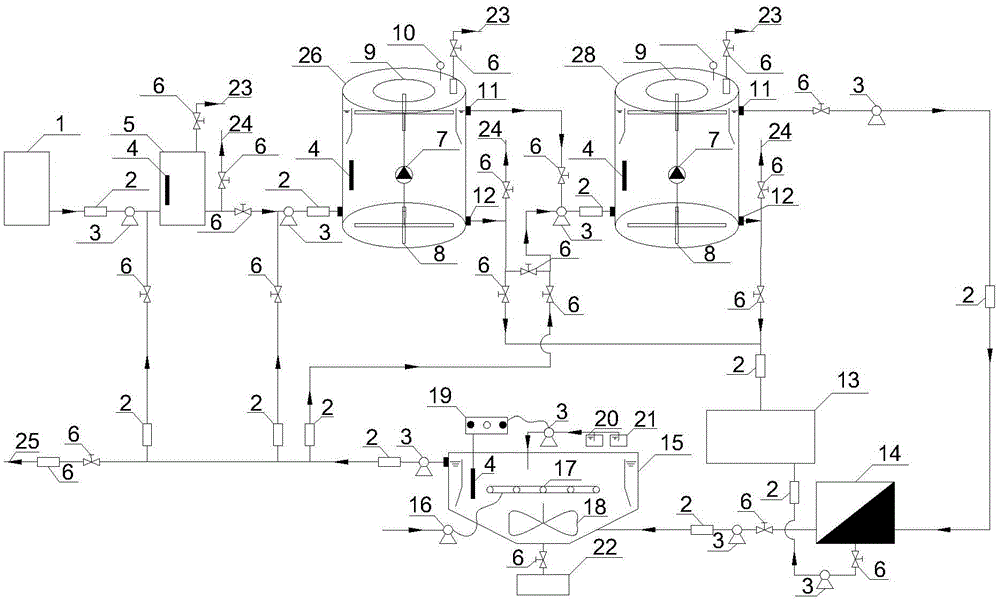

[0040] combine figure 1 To illustrate this embodiment, in this embodiment, a part of the biogas slurry treated by the fermentation liquid denitrification system is returned in equal amounts to the front ends of No. 1 fermenter 26, No. Reactor for fermentation. The food waste feed load of the whole fermentation system is increased to 1.2 times that of Example 1. Other connections and operating parameters are the same as in Example 1. The yields of hydrogen and methane in the fermentation system were 220-330ml / gVS and 610-900ml / gVS respectively. The recovery rate of struvite is 280-4000mg / L- biogas slurry. The concentration of ammonia nitrogen in the discharged biogas slurry is lower than 2700mg / L.

Embodiment 3

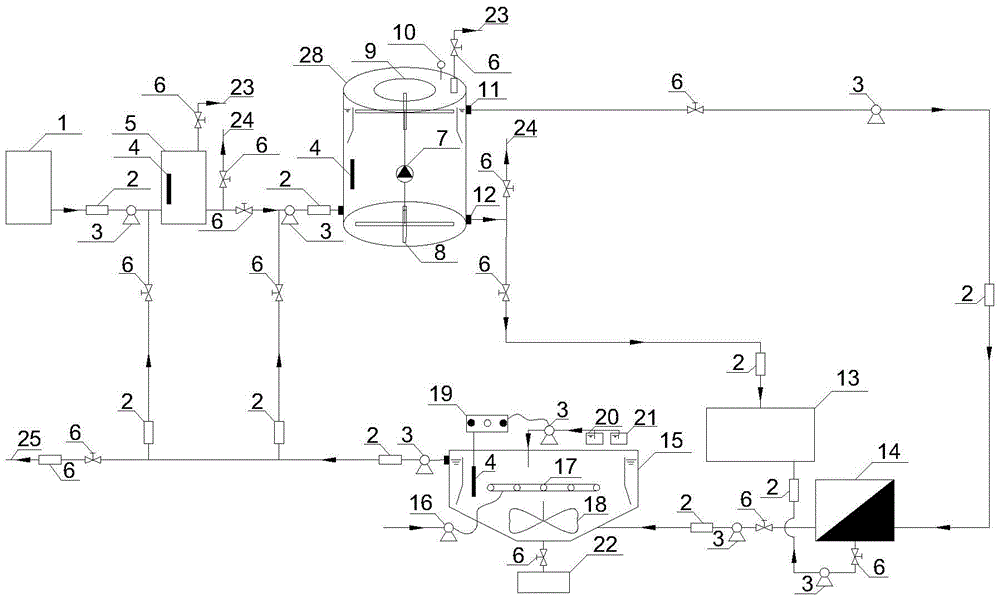

[0042] combine figure 2 To illustrate this embodiment, in this embodiment, the fermented liquid produced by No. 1 fermenter 26 enters No. 3 fermenter 28 through fermented liquid outlet 11, valve 6, pump 3 and flowmeter 2 for fermentation. Simultaneously, the fermentation residue produced by No. 1 fermenter 26 enters No. 3 fermenter 28 through residue discharge port 12, valve 6, pump 3 and flowmeter 2 for fermentation. The fermentation residue produced by the No. 3 fermentation tank 28 is discharged to the biogas residue treatment system 13 through the residue discharge port 12 , the valve 6 and the flow meter 2 . The hydraulic retention time of the fermented liquid in No. 3 fermenter 28 is 35 days. The fermented liquid produced by the No. 3 fermenter 28 enters the solid-liquid separator 14 through the fermented liquid discharge port 11, the valve 6, the pump 3 and the flowmeter 2 for solid-liquid separation. Other connections and operating parameters are the same as in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com