Production technology for high-density culture of chlorella by utilizing fermentation method

A production process and fermentation culture technology, which is applied in the production process field of high-density cultivation of chlorella by fermentation method, can solve the problems of easy pollution, low quality, and low density of algae cells, so as to reduce production costs, increase protein content, and shorten abnormal The effect of the incubation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

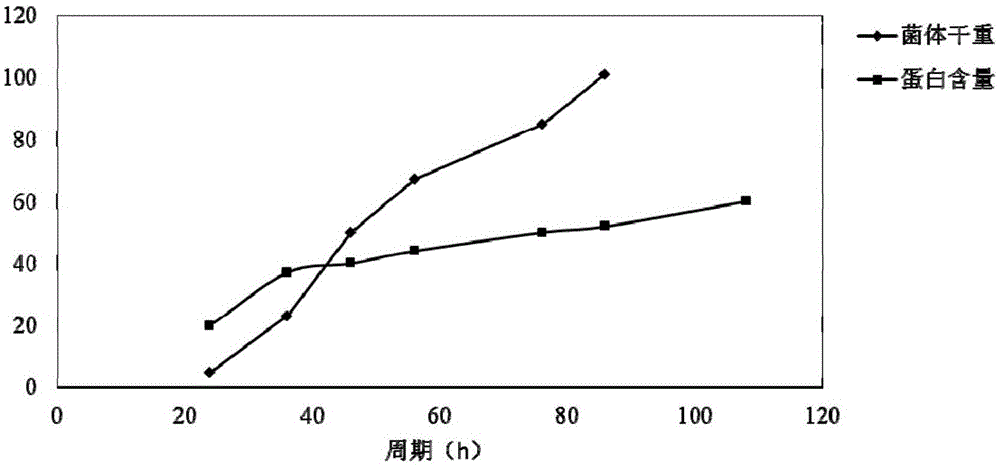

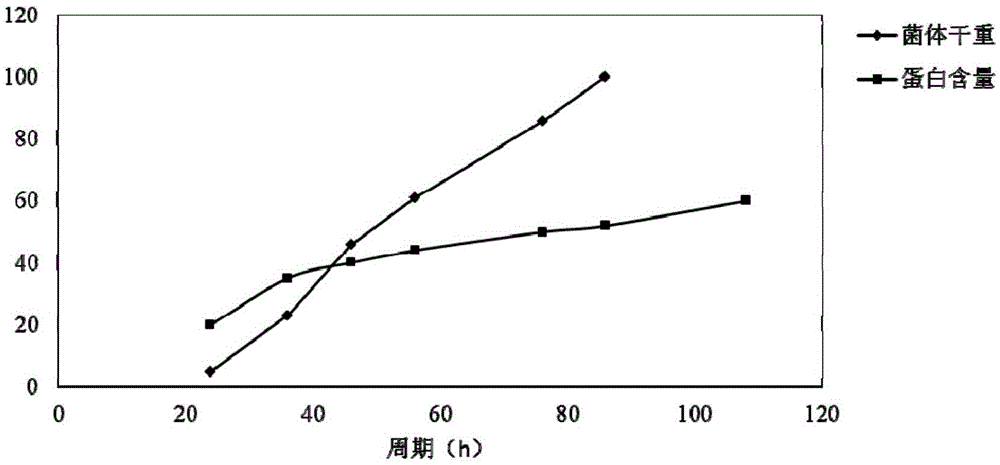

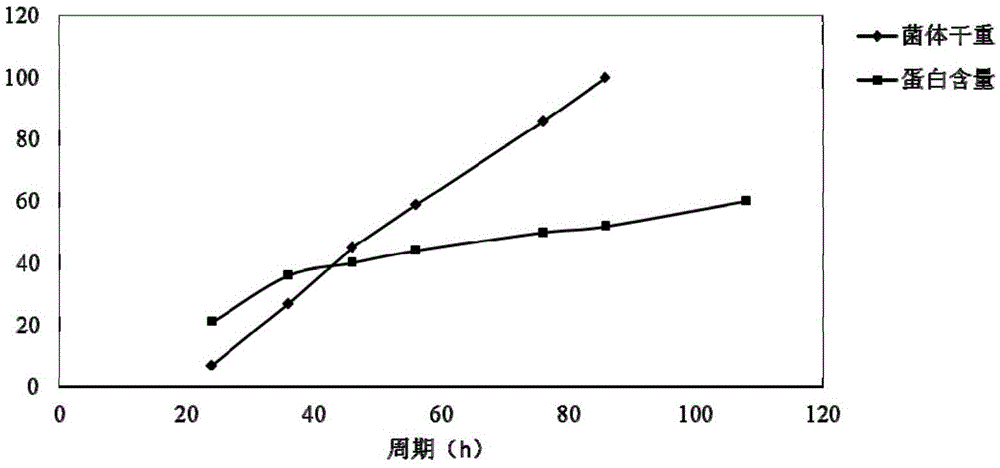

Image

Examples

Embodiment 1

[0042] The present invention, the production technique of chlorella, specifically adopts following method:

[0043] (1) Put the activated Chlorella algae and the newly connected shake flask into the shaker for light culture. After 3 days of normal culture, insert it into the 5L shake flask according to the subculture operation and cultivate it for 2 generations. Continue to pass on to the third generation. During generation, cultivate under light in a shaker, and after 3 days of normal culture, the concentration of the algae liquid reaches 10g / L;

[0044] (2) Step (1) is used to cultivate the chlorella seed solution in the logarithmic phase of growth, and insert it into a 150L seed tank by 10% (v / v) to carry out different culture;

[0045] 150L seed tank with fixed capacity of 100L,

[0046] The medium formula is:

[0047] Glucose: 30-60g / L, magnesium sulfate: 0.5-1.6g / L, calcium citrate: 0.1-0.5g / L, sodium phosphate: 1.0-2.0g / L, dipotassium hydrogen phosphate: 0.3-0.8g / L ,...

Embodiment 2

[0078] The present invention, the production technique of chlorella, specifically adopts following method:

[0079] (1) Put the activated Chlorella algae and the newly connected shake flask into the shaker for light culture. After 3 days of normal culture, insert it into the 5L shake flask according to the subculture operation and cultivate it for 2 generations. Continue to pass on to the third generation. During the generation, culture in the shaker under light, and after 3 days of normal culture, the concentration of the algae liquid reaches 8g / L;

[0080] (2) The chlorella seed solution cultivated in step (1) to the logarithmic phase of growth is inserted into a 150L seed tank at 10% (v / v) for abnormal cultivation;

[0081] 150L seed tank with fixed capacity of 100L;

[0082] The medium formula is as follows:

[0083] Glucose: 30-60g / L, magnesium sulfate: 0.5-1.6g / L, calcium citrate: 0.1-0.5g / L, sodium phosphate: 1.0-2.0g / L, dipotassium hydrogen phosphate: 0.3-0.8g / L , f...

Embodiment 3

[0114] The present invention, the production technique of chlorella, specifically adopts following method:

[0115] (1) Put the activated Chlorella algae and the newly connected shake flask into the shaker for light culture. After 3 days of normal culture, insert it into the 5L shake flask according to the subculture operation and cultivate it for 2 generations. Continue to pass on to the third generation. During the generation, culture in the shaker under light, after 3 days of normal culture, the concentration of the algae liquid reaches 11g / L;

[0116] (2) Step (1) is used to cultivate the chlorella seed solution in the logarithmic phase of growth, and insert it into a 150L seed tank by 10% (v / v) to carry out different culture;

[0117] 150L seed tank with fixed capacity of 100L;

[0118] The medium formula is as follows:

[0119] Glucose: 30-60g / L, magnesium sulfate: 0.5-1.6g / L, calcium citrate: 0.1-0.5g / L, sodium phosphate: 1.0-2.0g / L, dipotassium hydrogen phosphate: 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com