Ceramic-metal composite liner plate for large semi-autogenous mill and casting method of ceramic-metal composite liner plate

A metal composite and semi-autogenous grinding machine technology, applied in the field of mechanical parts manufacturing, can solve the problems of low hardness, poor wear resistance, short service life, etc., to improve density, facilitate exhaust and feeding, and prevent blowback and splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

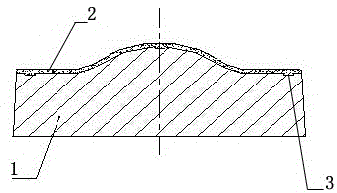

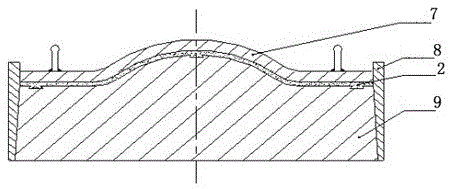

[0031] A ceramic-metal composite liner for a large semi-autogenous mill. A ceramic composite layer is arranged on a metal substrate. The chemical composition of the metal substrate and the weight percentages of each component are: C: 0.6%, Mn: 1.0%, Si: 1.0%, Cr: 2.2%, Mo: 0.8%, Ni: 1.0%, Cu: 0.15%, La: 0.01%, P2 o 3 Powder, 4% borax and 4% phenolic resin, the trough thickness of the liner is 160mm, and the weight is 1650kg.

[0032]The casting method of the ceramic-metal composite liner for a large semi-autogenous mill includes a casting process and a heat treatment process:

[0033] (1) Casting process

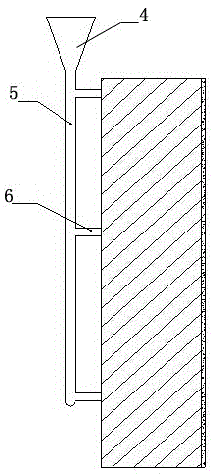

[0034] The process adopts the lost foam negative pressure casting process, including the following steps:

[0035] Making the liner model: First, prepare the matrix model with EPS and pre-open multiple dovetail grooves on its upper surface, place it in the mold frame after drying, and then, according to the weight percentage, use mechanical powder mixing equipment to mix 2...

Embodiment 2

[0042] A ceramic-metal composite liner for a large semi-autogenous mill. A ceramic composite layer is arranged on a metal substrate. The chemical composition of the metal substrate and the weight percentages of each component are: C: 0.55%, Mn: 1.2%, Si: 0.9%, Cr: 2.0%, Mo: 0.7%, Ni: 0.7%, Cu: 0.1%, La: 0.02%, P2 o 3 Powder, 6% borax and 4% phenolic resin, the trough thickness of the liner is 165mm, and the weight is 1760kg.

[0043] The casting method of the ceramic-metal composite liner for a large semi-autogenous mill includes a casting process and a heat treatment process:

[0044] (1) Casting process

[0045] The process adopts the lost foam negative pressure casting process, including the following steps:

[0046] Making the liner model: first, prepare the matrix model with EPS and pre-open multiple dovetail grooves on its upper surface, place it in the mold frame after drying, and then, according to the weight percentage, use mechanical powder mixing equipment to mix ...

Embodiment 3

[0053] A ceramic-metal composite liner for a large semi-autogenous mill. A ceramic composite layer is arranged on a metal substrate. The chemical composition of the metal substrate and the weight percentages of each component are: C: 0.65%, Mn: 0.8%, Si: 0.7%, Cr: 2.5%, Mo: 0.6%, Ni: 0.8%, Cu: 0.2%, La: 0.02%, P2 o 3 Powder, 5% borax and 4% phenolic resin, the trough thickness of the liner is 150mm, and the weight is 1580kg.

[0054] The casting method of the ceramic-metal composite liner for a large semi-autogenous mill includes a casting process and a heat treatment process:

[0055] (1) Casting process

[0056] The process adopts the lost foam negative pressure casting process, including the following steps:

[0057] Making the liner model: first, prepare the matrix model with EPS and pre-open multiple dovetail grooves on its upper surface, place it in the mold frame after drying, and then, according to the weight percentage, use mechanical powder mixing equipment to mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com